Managing assets effectively is crucial for ensuring the smooth operation and longevity of wastewater systems. Specifying engineers play a key role in this process, as they are responsible for selecting and designing the assets that make up these systems. In this comprehensive guide, we will explore the fundamentals of asset management, the principles of effective asset management, the lifecycle of wastewater assets, the role of technology in asset management, regulatory compliance, and future trends in the industry.

Understanding the Basics of Asset Management

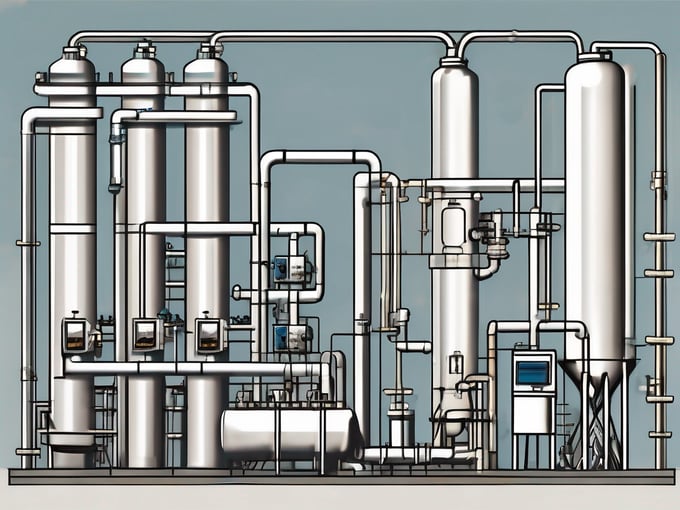

Asset management is the systematic approach to acquiring, operating, maintaining, and disposing of assets to optimize their performance and value. In the wastewater industry, this involves managing the infrastructure, equipment, and systems that collect, treat, and dispose of wastewater.

Asset management is a critical aspect of the wastewater industry, as it ensures the efficient and effective operation of wastewater treatment systems. By implementing asset management practices, organizations can minimize failures, extend asset lifespan, reduce costs, and enhance the overall efficiency of wastewater systems.

When it comes to asset management in the wastewater industry, there are several key components that need to be considered. These include asset inventory and condition assessment, risk management, maintenance planning, and asset performance monitoring.

Defining Asset Management in the Wastewater Industry

In the wastewater industry, asset management encompasses a range of activities aimed at ensuring the optimal performance and longevity of assets. Asset inventory and condition assessment involve identifying and cataloging all assets within a wastewater system, as well as assessing their current condition.

Risk management is another crucial aspect of asset management in the wastewater industry. It involves identifying potential risks and developing strategies to mitigate them. This could include implementing preventive maintenance programs, conducting regular inspections, and investing in backup systems to minimize the impact of asset failures.

Maintenance planning is an integral part of asset management in the wastewater industry. It involves developing comprehensive maintenance schedules and procedures to ensure that assets are properly maintained and serviced. This includes routine maintenance tasks such as cleaning, lubrication, and calibration, as well as more complex repairs and replacements.

Asset performance monitoring is essential for effective asset management in the wastewater industry. It involves continuously monitoring the performance of assets to identify any deviations from expected performance levels. This could include monitoring parameters such as flow rates, pressure levels, and energy consumption. By closely monitoring asset performance, organizations can detect potential issues early on and take proactive measures to address them.

The Role of Specifying Engineers in Asset Management

Specifying engineers play a crucial role in asset management within the wastewater industry. They are responsible for selecting the appropriate assets based on the specific requirements of the wastewater treatment process, regulatory standards, and budget constraints.

Specifying engineers work closely with stakeholders to understand the unique needs of the wastewater system and identify the most suitable assets. This involves conducting thorough research, evaluating different options, and considering factors such as performance, reliability, and cost-effectiveness.

Once the assets are selected, specifying engineers are involved in the design phase, ensuring that the assets are integrated seamlessly into the wastewater system. They collaborate with maintenance and operations teams to develop maintenance plans, identify potential risks, and address any asset performance issues that may arise.

Throughout the asset lifecycle, specifying engineers provide ongoing technical support. They work closely with vendors and contractors to ensure that the assets are installed correctly and meet the required specifications. They also stay updated on the latest advancements in asset management practices and technologies to continuously improve the performance and efficiency of wastewater systems.

In conclusion, asset management is a critical aspect of the wastewater industry. By implementing effective asset management practices and involving specifying engineers, organizations can ensure the optimal performance, longevity, and cost-effectiveness of their wastewater systems.

Key Principles of Effective Asset Management

While asset management practices can vary between organizations, there are several key principles that underpin effective asset management in the wastewater industry.

Effective asset management is crucial in the wastewater industry to ensure the smooth operation of infrastructure and to minimize costs. By implementing strategic planning, risk management, and asset performance monitoring, specifying engineers can optimize asset performance and enhance overall efficiency.

The Importance of Strategic Planning

Strategic planning is essential for aligning asset management goals with the overall objectives of the organization. It involves conducting risk assessments, setting performance targets, and developing long-term plans to optimize asset performance and minimize costs.

During the strategic planning process, specifying engineers consider various factors such as the age of assets, expected lifespan, and budget constraints. By establishing clear objectives and strategies, they can prioritize investments, allocate resources effectively, and ensure that asset management activities are aligned with business priorities.

Furthermore, strategic planning enables organizations to anticipate future needs and adapt to changing circumstances. It allows for the identification of potential risks and the development of contingency plans to mitigate them.

Risk Management and Asset Performance

Risk management plays a crucial role in asset management. Specifying engineers must identify the risks associated with each asset and develop strategies to mitigate them. This involves understanding potential failure modes, assessing the consequences of failures, and implementing preventive and corrective measures.

By conducting thorough risk assessments, specifying engineers can identify vulnerabilities in the wastewater infrastructure. They can then develop strategies to minimize the likelihood of failures and reduce the impact of any potential disruptions. This proactive approach helps to ensure the continuous and reliable operation of assets.

Monitoring asset performance is another integral part of risk management. By collecting and analyzing data on asset condition, availability, and reliability, specifying engineers can identify performance trends, anticipate failures, and schedule maintenance activities proactively.

Through regular inspections and condition assessments, specifying engineers can identify signs of deterioration or wear in assets. This allows for timely repairs or replacements, preventing major failures and costly emergency repairs. Additionally, by monitoring asset performance, engineers can optimize maintenance schedules, reducing downtime and maximizing asset lifespan.

Moreover, asset performance monitoring provides valuable data for decision-making. By analyzing performance trends, specifying engineers can identify areas for improvement and implement strategies to enhance asset efficiency and reliability.

In conclusion, effective asset management in the wastewater industry relies on strategic planning, risk management, and asset performance monitoring. By implementing these key principles, specifying engineers can optimize asset performance, minimize costs, and ensure the reliable operation of wastewater infrastructure.

The Lifecycle of Wastewater Assets

Assets in the wastewater industry go through a lifecycle that involves various stages, from asset acquisition and installation to operation, maintenance, and disposal.

Asset Acquisition and Installation

During asset acquisition, specifying engineers evaluate different options, considering factors such as performance, cost, and compatibility with existing systems. They collaborate with suppliers to ensure that the assets meet the required specifications and regulatory standards.

Asset acquisition is a complex process that involves extensive research and analysis. Specifying engineers carefully assess the needs of the wastewater treatment facility and consider the long-term goals of the organization. They take into account factors such as the capacity of the assets, their durability, and their ability to handle different types of wastewater.

Once the assets are selected, the installation phase begins. This is a critical phase that requires careful planning and coordination. Specifying engineers work closely with contractors and construction teams to ensure that the assets are installed correctly. They verify that all the necessary connections are made, and that the assets are aligned and secured properly.

During the installation process, specifying engineers conduct initial testing to ensure that the assets are functioning as expected. They also provide training to the operations and maintenance teams, equipping them with the knowledge and skills necessary to operate and maintain the assets effectively.

Operation and Maintenance of Assets

Once the assets are in operation, specifying engineers oversee their performance and maintenance. They develop maintenance plans based on asset condition and criticality, ensuring that preventive and corrective actions are implemented to maximize asset reliability and availability.

Specifying engineers work closely with operations and maintenance teams to monitor the assets' performance. They regularly inspect the assets, checking for any signs of wear and tear or potential issues. By conducting routine inspections, they can identify and address any maintenance needs promptly, minimizing the risk of asset failure or downtime.

In addition to maintenance, specifying engineers also play a role in optimizing asset performance. They monitor key performance indicators, such as flow rates, pressure levels, and energy consumption. By analyzing data and trends, they can identify opportunities for efficiency improvements and process optimization. This may involve adjusting operational parameters, implementing new technologies, or making modifications to the assets.

Asset Disposal and Replacement

At the end of their lifecycle, assets need to be disposed of properly. Specifying engineers coordinate the disposal process, ensuring compliance with environmental regulations and identifying opportunities for asset reuse or recycling.

Asset disposal is a critical step in the lifecycle, as it involves the proper handling and disposal of potentially hazardous materials. Specifying engineers work closely with waste management companies to ensure that the assets are disposed of in an environmentally responsible manner. They may explore options for asset reuse or recycling, minimizing the environmental impact of the disposal process.

Asset replacement is another important aspect of the lifecycle. As technology advances and wastewater treatment requirements evolve, specifying engineers evaluate the performance and condition of existing assets. They consider factors such as the assets' efficiency, capacity, and compatibility with new technologies. Based on their assessment, they plan for upgrades or replacements to ensure the continued effectiveness of the wastewater treatment system.

Asset replacement involves careful planning and budgeting. Specifying engineers collaborate with financial teams to assess the costs and benefits of replacing assets. They consider factors such as the expected lifespan of the new assets, the potential energy savings, and the impact on overall system performance. By making informed decisions, they can ensure that the wastewater treatment facility remains efficient and compliant with regulatory standards.

The Role of Technology in Asset Management

Technology plays a crucial role in modern asset management practices. It enables specifying engineers to streamline their processes, enhance data analysis capabilities, and improve decision-making.

Asset management is a complex and multifaceted discipline that involves the tracking, maintenance, and optimization of physical assets. With the rapid advancements in technology, asset management has been revolutionized, allowing organizations to achieve higher levels of efficiency and effectiveness.

Utilizing Digital Tools for Asset Tracking

Asset tracking systems, including databases, barcoding, and RFID (Radio Frequency Identification) tags, help specifying engineers maintain accurate asset inventories. These tools facilitate the tracking of assets throughout their lifecycle, making it easier to schedule maintenance activities, monitor performance, and optimize resource allocation.

For example, barcoding systems enable engineers to quickly scan assets and update their status in a centralized database. This eliminates the need for manual data entry and reduces the chances of errors or discrepancies. RFID tags, on the other hand, provide real-time visibility of assets, allowing engineers to locate and track them with ease.

By leveraging digital tools for asset tracking, organizations can improve their inventory management, minimize the risk of asset loss or theft, and ensure compliance with regulatory requirements.

Predictive Maintenance and IoT in the Wastewater Industry

The Internet of Things (IoT) allows for real-time monitoring of assets, enabling predictive maintenance practices. Specifying engineers can leverage IoT sensors and data analytics to detect anomalies, predict failures, and schedule maintenance activities before asset performance is compromised.

In the wastewater industry, where asset reliability is crucial for uninterrupted operations, predictive maintenance has become increasingly important. By continuously monitoring key parameters such as flow rates, pressure levels, and equipment vibrations, engineers can identify potential issues and take proactive measures to prevent failures.

IoT sensors embedded in wastewater treatment plants can collect vast amounts of data, which can be analyzed using advanced algorithms and machine learning techniques. This analysis helps engineers identify patterns, correlations, and trends that may indicate impending asset failures. By acting upon these insights, organizations can minimize unplanned downtime, reduce maintenance costs, and optimize asset lifespan.

Furthermore, IoT-enabled asset management systems can integrate with enterprise resource planning (ERP) software, allowing for seamless coordination between maintenance activities, inventory management, and financial planning. This integration enhances the overall efficiency and effectiveness of asset management practices.

In conclusion, technology has transformed asset management by providing powerful tools for asset tracking and enabling predictive maintenance practices. As organizations continue to embrace technological advancements, the role of technology in asset management will only become more prominent, driving further improvements in operational efficiency and cost-effectiveness.

Regulatory Compliance and Asset Management

Regulatory compliance is a critical aspect of asset management in the wastewater industry. Specifying engineers must ensure that assets meet the relevant regulatory standards and requirements throughout their lifecycle.

Understanding Wastewater Regulations

Specifying engineers need to have a comprehensive understanding of wastewater regulations to ensure compliance. This involves staying updated on regulatory changes, conducting regular audits, and collaborating with regulatory agencies to address any compliance issues.

Wastewater regulations are put in place to protect public health and the environment. These regulations outline the permissible levels of pollutants that can be discharged into water bodies, as well as the treatment processes that need to be followed. They also cover aspects such as monitoring and reporting requirements, ensuring that wastewater treatment facilities are operating efficiently and effectively.

Staying updated on regulatory changes is crucial for specifying engineers. Regulations can be revised or updated periodically to reflect new scientific knowledge, technological advancements, or changing environmental priorities. By staying informed, engineers can ensure that the assets they manage remain compliant with the latest standards.

Regular audits are another important aspect of understanding wastewater regulations. These audits involve a thorough examination of the wastewater treatment facility's operations, processes, and documentation to ensure compliance. Audits can be conducted internally or by third-party organizations specializing in regulatory compliance. They help identify any gaps or areas of improvement, allowing engineers to take corrective actions and maintain compliance.

Collaboration with regulatory agencies is essential for addressing compliance issues. Specifying engineers work closely with these agencies to seek guidance, clarify regulations, and resolve any compliance-related challenges. This collaboration ensures that the assets they manage align with the goals and requirements set by the regulatory bodies.

Ensuring Compliance through Effective Asset Management

Effective asset management practices, such as regular inspections, preventive maintenance, and performance monitoring, are instrumental in maintaining regulatory compliance. Specifying engineers implement measures to ensure that assets meet the required standards and mitigate any risks that could lead to non-compliance.

Regular inspections play a crucial role in asset management for regulatory compliance. These inspections involve visual assessments, testing, and monitoring of various components of the wastewater treatment facility. By identifying any signs of wear and tear, corrosion, or malfunctioning equipment, engineers can take timely actions to rectify the issues and prevent any potential non-compliance.

Preventive maintenance is another key aspect of effective asset management. By following a scheduled maintenance plan, engineers can ensure that all equipment and systems are operating optimally. This includes regular cleaning, lubrication, calibration, and replacement of worn-out parts. Preventive maintenance not only extends the lifespan of assets but also reduces the likelihood of unexpected breakdowns or failures that could result in non-compliance.

Performance monitoring is essential for maintaining regulatory compliance. Engineers utilize various monitoring techniques, such as flow meters, water quality analyzers, and data loggers, to continuously assess the performance of the wastewater treatment facility. By monitoring parameters such as pollutant levels, treatment efficiency, and energy consumption, engineers can identify any deviations from the regulatory requirements and take corrective actions promptly.

In addition to inspections, maintenance, and monitoring, asset management for regulatory compliance also involves record-keeping and documentation. Engineers maintain detailed records of inspections, maintenance activities, performance data, and any non-compliance incidents. These records serve as evidence of compliance and can be used for audits, reporting to regulatory agencies, and future reference.

By implementing these asset management practices, specifying engineers ensure that the assets under their management remain compliant with the regulatory standards. They not only protect public health and the environment but also contribute to the overall sustainability and efficiency of wastewater treatment operations.

Future Trends in Asset Management for the Wastewater Industry

The asset management landscape is continually evolving, driven by technological advancements and changing industry demands. Specifying engineers need to stay abreast of these trends to remain effective in their roles.

The Impact of Sustainability on Asset Management

Sustainability is becoming increasingly important in asset management practices. Specifying engineers are encouraged to design and select assets that minimize environmental impact, conserve resources, and increase energy efficiency. They must consider the lifecycle environmental impact and incorporate sustainable practices throughout the asset management process.

The Role of AI and Machine Learning in Future Asset Management

Artificial Intelligence (AI) and Machine Learning are poised to transform asset management in the wastewater industry. These technologies can analyze vast amounts of data, predict asset performance, and optimize maintenance strategies.

Specifying engineers can leverage AI and Machine Learning algorithms to automate tasks, identify patterns, and make data-driven decisions, leading to more efficient asset management practices.

In conclusion, effective asset management is crucial for specifying engineers in the wastewater industry. By understanding the basics of asset management, following key principles, managing the lifecycle of assets, utilizing technology, ensuring regulatory compliance, and staying ahead of future trends, specifying engineers can optimize asset performance, minimize costs, and contribute to the sustainable and efficient operation of wastewater systems.