Chlorine Injection for Well Water: A Comprehensive Guide

Ensuring safe, clean water is paramount for any household, especially those relying on well water. One effective method for achieving this is chlorine injection, a process that sanitizes water by eliminating harmful microorganisms. This guide provides a detailed overview of chlorine injection, from its fundamental principles to its impact on the environment, ensuring you have all the information needed to make informed decisions about your water treatment options.

Understanding Chlorine Injection

Chlorine injection is a widely accepted practice in treating well water. This method involves adding chlorine to water systems to eradicate pathogens and improve water quality. Understanding its mechanics is essential for implementing it effectively in your water treatment process.

The Basics of Chlorine Injection

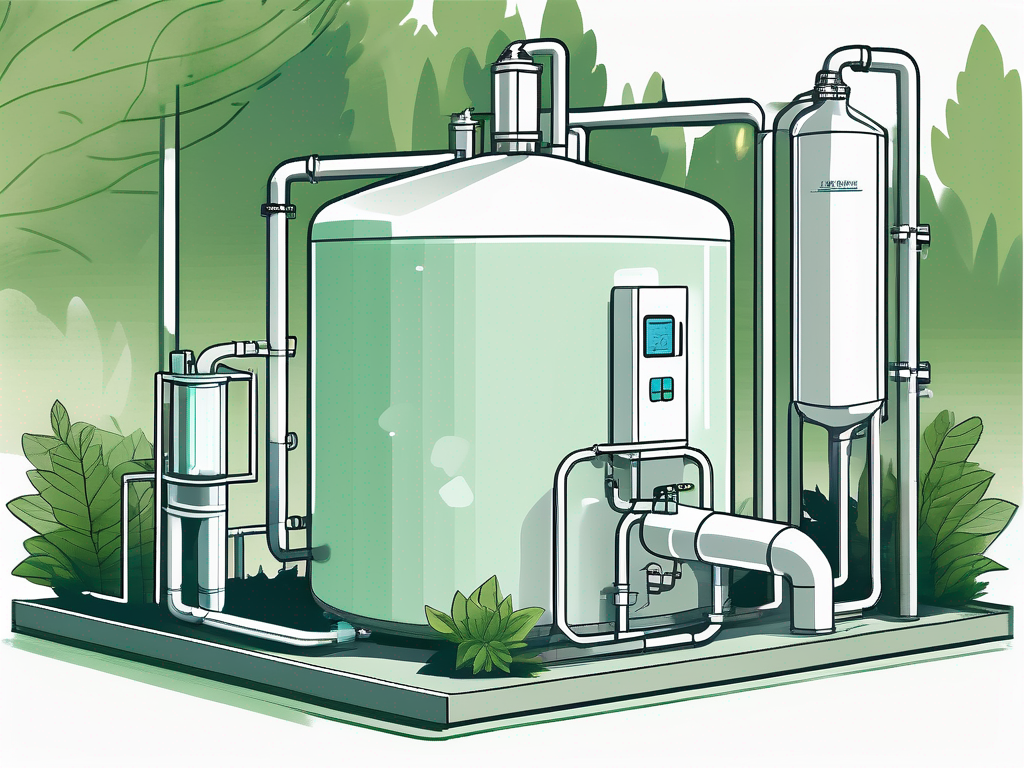

At its core, chlorine injection involves the precise introduction of chlorine into the water supply. This can be done continuously or as a shock treatment, depending on the specific needs of the water system. The process is often automated through injection pumps that ensure the right dosage is delivered consistently.

The chlorine typically used comes in various forms, including liquid chlorine, gas, or solid tablets. Each has its pros and cons, but the goal remains the same: achieving optimal disinfection to provide clean, safe drinking water. Liquid chlorine, for instance, is often favored for its ease of use and effectiveness, while solid tablets may be preferred for their convenience and lower risk of handling hazards.

Importance of Chlorine in Water Treatment

The necessity of chlorine in water treatment can hardly be overstated. Chlorine is not just a disinfectant; it’s a chemical agent that combats a wide array of harmful microorganisms. Effective against bacteria, viruses, and other pathogens, chlorine ensures that any water sourced from wells is safe for consumption.

Additionally, chlorine helps to prevent the regrowth of pathogens in the distribution system. By maintaining a residual level of chlorine in the water, households can defend against potential contaminants that may infiltrate the supply from various sources. This is particularly crucial in areas where water quality can fluctuate due to environmental changes or infrastructure issues. Moreover, chlorine's role extends beyond mere disinfection; it also aids in the oxidation of iron and manganese, which can lead to clearer water and reduced staining in plumbing fixtures.

Furthermore, the use of chlorine in water treatment is supported by extensive research and regulatory guidelines, ensuring that it is applied safely and effectively. Water treatment facilities often conduct regular testing to monitor chlorine levels, ensuring they remain within the recommended limits for safe consumption. This rigorous oversight not only protects public health but also instills confidence in the water supply, allowing communities to thrive with access to clean, potable water.

The Science Behind Chlorine Injection

The effectiveness of chlorine injection is rooted in chemistry. Understanding the science behind the process can offer insights into why it works and how to apply it safely and effectively.

How Chlorine Kills Bacteria and Viruses

Chlorine acts as a potent antimicrobial agent. When introduced into water, it disrupts the cellular structure of bacteria and viruses, leading to their eventual destruction. The chlorination process generates hypochlorous acid and hypochlorite ions, both of which are capable of penetrating microorganisms and interfering with their biochemical processes.

This mode of action makes chlorine exceptionally effective against pathogens such as E. coli and Giardia, which are commonly found in contaminated well water. The speed and efficacy with which chlorine works make it a staple in water treatment protocols worldwide. Moreover, chlorine's ability to form a residual disinfectant means that it continues to protect water as it travels through pipes, ensuring that consumers receive safe drinking water at the tap.

Chemical Reactions Involved in Chlorine Injection

The injection of chlorine into water involves several key chemical reactions. When chlorine meets water, it reacts with it to form hydrochloric acid and hypochlorous acid. These chemicals play critical roles in the disinfection process.

Interestingly, the concentration of chlorine and the contact time are vital factors that determine the overall effectiveness of the treatment. Higher concentrations and longer exposure times typically yield better disinfection results, but they must be managed carefully to avoid excessive chlorine levels that can produce harmful by-products. Additionally, various factors such as pH levels, temperature, and the presence of organic matter can influence the efficiency of chlorine disinfection. For instance, higher pH levels can reduce the effectiveness of hypochlorous acid, necessitating careful monitoring and adjustment to maintain optimal conditions for disinfection.

Different Methods of Chlorine Injection

There are various methods for chlorine injection, each tailored to different needs, budgets, and water quality specifications. Knowing these methods helps in deciding which approach is best suited for your well water treatment.

Liquid Chlorine Injection

This method involves the direct injection of liquid chlorine into the water supply. It is one of the most common techniques used in residential and commercial applications due to its effectiveness and ease of use. Liquid chlorine provides immediate results and is usually stored in a tank connected to an injection pump.

However, users must take care when handling liquid chlorine, as it can be corrosive and harmful. Proper storage and management practices are essential for safety. Regular maintenance of the injection system is also crucial to ensure that the chlorine is being dispensed at the correct dosage, which is vital for effective disinfection and to prevent any potential adverse effects on the water quality.

Chlorine Gas Injection

Chlorine gas injection involves using gaseous chlorine, which is then mixed with water to create a chlorine solution. This method is often employed in larger treatment facilities due to the need for specialized equipment and precautions when handling gas. The concentration levels of chlorine can be tightly controlled, providing a very effective disinfectant.

This method is highly efficient, but its complexity means that it is typically reserved for larger-scale operations rather than individual households. Facilities utilizing chlorine gas must implement rigorous safety protocols, including gas detection systems and emergency response plans, to mitigate the risks associated with chlorine gas leaks. Additionally, staff must be trained in handling hazardous materials to ensure compliance with safety regulations.

Chlorine Tablet Injection

Chlorine tablets are a convenient option for those looking to treat their well water. These tablets dissolve at a controlled rate, releasing chlorine gradually into the water supply. This method allows for quieter operation and easier handling than liquid versions.

While chlorine tablets offer safety and simplicity, it's essential to choose the right type of tablet according to your system’s specifications and water quality needs. They can be an excellent option for smaller systems or intermittent use. Furthermore, the use of tablets can reduce the risk of over-chlorination, as the controlled release mechanism helps maintain consistent chlorine levels. Users should also consider the environmental impact of chlorine tablets, as some formulations may contain additives that can affect water quality. Regular testing of water quality is recommended to ensure that the chlorine levels remain within safe limits, providing effective disinfection without compromising the health of the ecosystem.

Safety Measures in Chlorine Injection

Implementing chlorine injection systems does come with its set of safety considerations. Understanding and following these measures ensures the safe handling of chlorine and minimizes potential hazards.

Handling and Storing Chlorine Safely

Chlorine must be treated with respect and caution. When handling chlorine solutions or gases, always wear appropriate personal protective equipment, including gloves and goggles. Store chlorine in labeled, sealed containers away from direct sunlight and heat sources to prevent accidental reactions or leaks.

Always keep chlorine products out of reach of children and pets to reduce the risk of accidental exposure. Regular training and safety drills can help ensure that all household members understand how to handle chlorine safely. Additionally, it is advisable to have a designated area for chlorine storage that is well-ventilated and equipped with emergency equipment, such as eyewash stations and safety showers, to address any accidental exposure quickly. Keeping a detailed inventory of chlorine supplies can also help in monitoring usage and ensuring that expired or unused products are disposed of properly.

Protective Equipment for Chlorine Injection

Using chlorine requires appropriate protective equipment to safeguard against potential hazards. Ideal protective gear includes:

- Gloves: Chemical-resistant gloves are essential to protect skin.

- Goggles: Eye protection prevents chlorine vapors from causing irritation.

- Respirators: In situations where there could be exposure to chlorine gas, a respirator is necessary.

Ensuring that all equipment is in good working condition and used correctly is key for safety during chlorine injection. Regular inspections of protective gear should be conducted to check for any signs of wear or damage, as compromised equipment can significantly increase the risk of exposure. Furthermore, it is important to educate all personnel on the correct procedures for donning and doffing protective equipment to avoid contamination. Training sessions can also include simulations of emergency scenarios, so that individuals are well-prepared to respond effectively in the event of an incident involving chlorine exposure.

Maintenance of Chlorine Injection Systems

Regular maintenance of chlorine injection systems is crucial for ensuring their effectiveness and longevity. Establishing a routine can prevent system failures and ensure consistent water quality. In addition to routine checks, it is also important to train staff on proper handling and operational procedures to minimize human error and enhance system reliability.

Regular System Checks and Balancing

Periodic inspection of chlorine injection systems, including reviewing the pump operation, tank levels, and chlorine concentrations, can help identify issues before they escalate. Balancing chlorine levels is essential to maintain water quality without exceeding safety thresholds. Furthermore, it is advisable to conduct these checks during different times of the day, as water demand and chemical reactions can vary, impacting chlorine efficacy. Regular calibration of monitoring equipment also ensures that readings are accurate, which is vital for maintaining compliance with health and safety regulations.

Keeping records of system performance can also help monitor any changes in operation, allowing for timely intervention if necessary. These logs can serve as valuable data for trend analysis, enabling operators to anticipate maintenance needs and optimize chemical dosing strategies based on historical performance.

Troubleshooting Common Issues

Common issues in chlorine injection can range from insufficient chlorine levels to equipment malfunctions. Understanding how to troubleshoot these problems is vital:

- If chlorine levels drop, check the pump and ensure it is operating correctly.

- Excess chlorine may indicate a malfunction in the monitoring system, requiring immediate attention.

- Monitor for odors that may indicate chlorine gas leaks, which must be addressed immediately.

Quick response to these issues can prevent more extensive problems down the line. Additionally, it is beneficial to familiarize oneself with the specific components of the chlorine injection system, such as the injector, flow meter, and check valves, as understanding their roles can aid in diagnosing issues more effectively. Regular training sessions can also empower staff to recognize unusual signs or symptoms of malfunction, further enhancing the system's reliability and safety.

Environmental Impact of Chlorine Injection

While chlorine injection is an effective water treatment method, it's essential to consider its environmental implications. The balance between safe water and environmental stewardship is crucial for sustainable practices. The use of chlorine has been a cornerstone in public health for decades, ensuring that pathogens are eliminated from drinking water. However, as our understanding of environmental science evolves, so too must our approach to water treatment, integrating methods that prioritize both human health and ecological integrity.

Chlorine and Water Ecosystems

The discharge of chlorinated water can negatively impact local ecosystems if not appropriately handled. Chlorine can harm aquatic life; therefore, it’s imperative to neutralize residual chlorine before water is released back into the environment. Fish, amphibians, and invertebrates are particularly sensitive to chlorine exposure, which can disrupt their reproductive systems and overall health. Moreover, the formation of chlorinated byproducts, such as trihalomethanes, can further exacerbate environmental issues, leading to long-term contamination of water bodies.

Understanding local regulations regarding chlorine discharge is vital for compliance and environmental protection. Using dechlorination methods can help mitigate these impacts. Techniques such as activated carbon filtration, chemical neutralization, or ultraviolet light treatment can effectively reduce chlorine levels before water is returned to natural habitats. Additionally, monitoring the health of local aquatic ecosystems can provide valuable feedback on the effectiveness of these mitigation strategies, fostering a more responsive approach to water treatment practices.

Responsible Use of Chlorine

Responsible use of chlorine in water treatment includes minimizing chemical usage while ensuring efficacy. Employing the right dosage based on regular testing for water quality can help maintain an effective balance. This not only protects the environment but also enhances the safety and taste of drinking water. Advanced technologies, such as automated dosing systems, can optimize chlorine application, ensuring that only the necessary amounts are used, thus reducing the risk of over-chlorination.

Engaging with local environmental agencies can provide additional guidelines on sustainable practices, protecting both public health and local ecosystems. Collaboration with these agencies can lead to the development of community-focused initiatives aimed at raising awareness about the importance of responsible chlorine use. Educational programs can empower residents to understand the implications of water treatment methods and encourage them to advocate for practices that prioritize both water safety and environmental health. Furthermore, exploring alternative disinfection methods, such as ozone or hydrogen peroxide, could pave the way for a more sustainable future in water treatment, aligning public health goals with ecological preservation.

Alternatives to Chlorine Injection

For those seeking alternatives to chlorine injection, various water treatment methods are available, each with different advantages. Understanding these options can lead to better-informed decisions.

UV Light Water Treatment

Ultraviolet (UV) light treatment is an increasingly popular method for disinfecting water without using chemicals. UV light effectively neutralizes bacteria and viruses by damaging their DNA, rendering them harmless. This method is especially desirable for those looking to avoid chlorine's taste and smell. The process is quick and efficient, often requiring only a matter of seconds to treat water, making it suitable for both residential and commercial applications.

However, UV treatment does require clear water to be effective, which means additional pretreatment might be necessary in turbid situations. Moreover, while UV light can eliminate pathogens, it does not remove chemical contaminants or particulates, so it is often used in conjunction with other filtration methods to ensure comprehensive water quality.

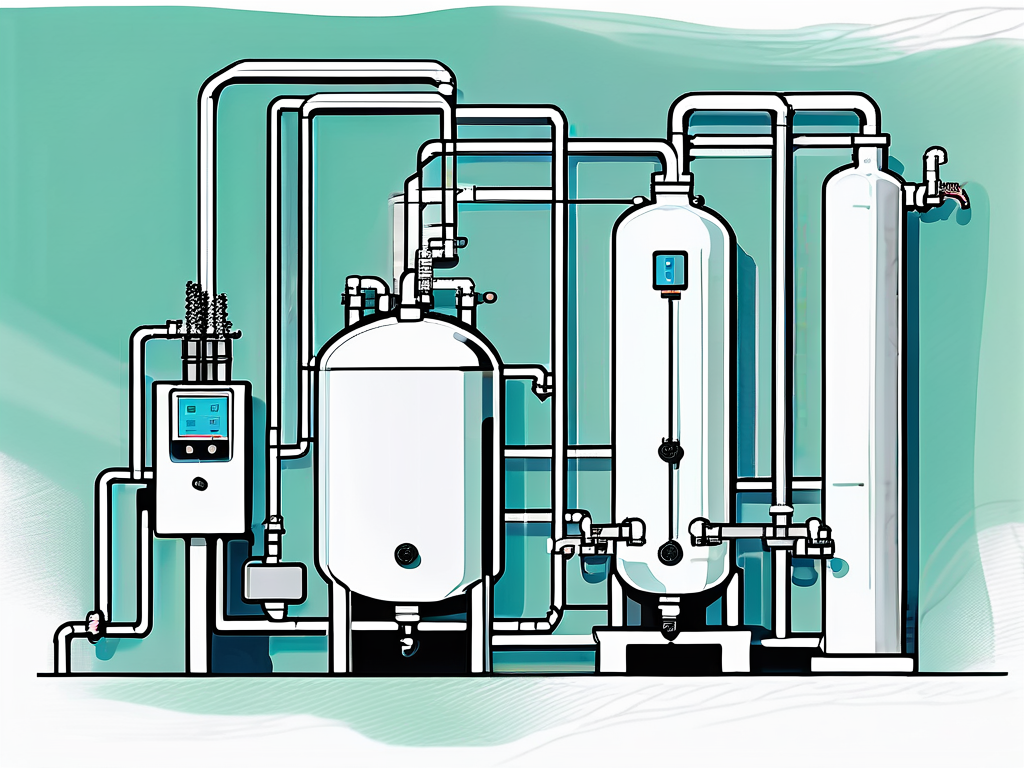

Ozone Water Treatment

Ozone treatment involves dissolving ozone gas into water, where it acts as a powerful oxidizing agent. Ozone is highly effective at killing pathogens and does not leave harmful residues like chlorinated compounds. This method can also help in the removal of unpleasant tastes and odors from water, making it particularly appealing for drinking water applications. Additionally, ozone has the ability to break down organic materials, which can further improve water quality.

However, ozone systems can be more expensive and complex, requiring careful monitoring and expertise. The short half-life of ozone means that it must be generated on-site and used immediately, which can pose logistical challenges for larger operations. Furthermore, while ozone is highly effective, it is important to ensure that the concentration levels are carefully controlled to avoid potential health risks associated with high ozone exposure.

Reverse Osmosis Systems

Reverse osmosis (RO) systems work by forcing water through a semipermeable membrane, effectively removing impurities, including microorganisms. This method provides excellent filtration, removing not only bacteria and viruses but also dissolved salts, heavy metals, and other contaminants. As a result, RO systems are often used in areas where water quality is a significant concern, such as in industrial applications or in regions with high levels of pollutants.

While reverse osmosis is highly effective, it does not specifically target pathogens like chlorine does, making it suitable for different applications. Additionally, RO systems can waste a considerable amount of water during the filtration process, which is an important factor to consider for those in water-scarce regions. Regular maintenance and replacement of the membranes are also necessary to ensure optimal performance, adding to the overall cost of the system.

When considering alternatives to chlorine injection, evaluate your specific needs, local water quality, and the pros and cons of each treatment option. Factors such as installation costs, maintenance requirements, and the specific contaminants present in your water supply should all play a role in your decision-making process. Understanding the nuances of each method can help you choose the best solution for your water treatment needs.

In conclusion, chlorine injection remains a vital process in treating well water, ensuring safety and quality for everyday use. Understanding its mechanics, methods, and safety involves comprehensively considering the benefits and responsibilities of using chlorine for disinfection.