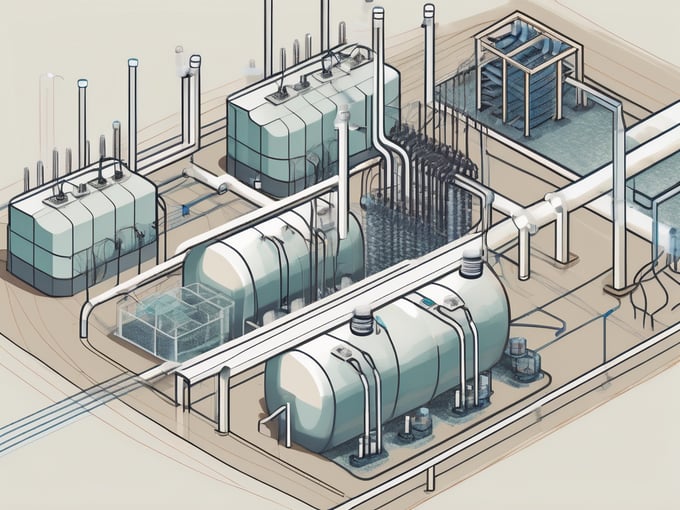

In the world of wastewater management, Ethernet/IP has emerged as a powerful tool for facilitating efficient operations and data management. With its ability to provide seamless connectivity and real-time monitoring, Ethernet/IP is revolutionizing the way wastewater applications are managed. This comprehensive guide aims to provide a deeper understanding of Ethernet/IP and its key components, as well as the benefits it offers in wastewater applications. Additionally, we will explore how to set up and maintain Ethernet/IP systems, as well as discuss future trends in this rapidly evolving technology.## Understanding Ethernet/IP in Wastewater Management

Defining Ethernet/IP

Ethernet/IP is an industrial communication protocol that enables the exchange of data between devices within a local area network (LAN). It is built on standard Ethernet and Internet Protocol (IP) technologies, making it compatible with a wide range of devices and systems. In the context of wastewater management, Ethernet/IP enables seamless data exchange between various components of the system, including sensors, programmable logic controllers (PLCs), human-machine interfaces (HMIs), and data storage units.

With the increasing demand for efficient and sustainable wastewater management solutions, the role of Ethernet/IP has become even more significant. By providing a reliable and standardized communication platform, Ethernet/IP ensures that all the devices and systems in a wastewater management network can seamlessly communicate with each other, enabling efficient data exchange and control.

Furthermore, Ethernet/IP offers several advantages over traditional communication protocols in wastewater management applications. Its compatibility with standard Ethernet and IP technologies means that it can leverage existing network infrastructure, reducing the need for additional hardware and cabling. This not only simplifies the installation process but also reduces costs associated with network expansion and maintenance.

Role of Ethernet/IP in Wastewater Applications

In wastewater applications, Ethernet/IP plays a crucial role in facilitating real-time monitoring and control. It allows operators to remotely monitor process variables such as flow rates, pressure levels, temperature, and chemical concentrations, ensuring optimal performance and adherence to regulatory requirements.

With Ethernet/IP, operators can access real-time data from various sensors and devices spread across the wastewater management system. This data provides valuable insights into the system's performance, allowing operators to identify potential issues and take proactive measures to address them. For example, if a sudden increase in flow rate is detected, operators can quickly investigate the cause and take necessary actions to prevent any adverse effects on the system.

Moreover, Ethernet/IP enables seamless integration of different components within the wastewater management system. For instance, PLCs can communicate with HMIs to provide operators with a user-friendly interface for monitoring and controlling the system. Data storage units can collect and store historical data, allowing operators to analyze trends and make informed decisions regarding system optimization and maintenance.

Another significant advantage of Ethernet/IP in wastewater applications is its ability to support remote access and control. Operators can securely access the system from anywhere, using authorized devices such as laptops or smartphones. This remote accessibility allows for efficient troubleshooting, reducing the need for on-site visits and minimizing downtime.

In conclusion, Ethernet/IP is a vital communication protocol in wastewater management, enabling seamless data exchange, real-time monitoring, and control. Its compatibility with standard Ethernet and IP technologies, along with its ability to integrate various components, makes it an ideal choice for efficient and reliable wastewater management systems.

Key Components of Ethernet/IP in Wastewater Applications

Ethernet/IP is a widely used communication protocol in wastewater applications, enabling efficient and reliable data transmission between devices. To implement Ethernet/IP in wastewater applications, certain hardware components and software specifications are essential. Let's take a closer look at these key components:

Hardware Requirements

When it comes to hardware requirements for Ethernet/IP in wastewater applications, several components play a crucial role in ensuring seamless communication and data transmission:

1. Industrial Ethernet Switches: Industrial-grade Ethernet switches are the backbone of Ethernet/IP systems. These switches provide reliable and uninterrupted communication between various devices, such as PLCs (Programmable Logic Controllers) and HMIs (Human Machine Interfaces). With features like high-speed data transfer and robust design, industrial Ethernet switches are capable of withstanding harsh environmental conditions commonly found in wastewater treatment plants.

2. Ethernet Cables: High-quality Ethernet cables are essential for fast and stable data transmission between devices in Ethernet/IP systems. These cables are designed to minimize signal loss and interference, ensuring reliable communication even over long distances. Shielded Ethernet cables are often used in wastewater applications to protect against electrical noise and other environmental factors that could affect data integrity.

3. Devices with Ethernet/IP Communication Capabilities: To establish an Ethernet/IP network in wastewater applications, devices equipped with Ethernet/IP communication capabilities are required. These devices, such as PLCs and HMIs, serve as endpoints in the network, facilitating the exchange of data between different components of the wastewater treatment system. With Ethernet/IP compatibility, these devices can seamlessly integrate into the network, enabling efficient control and monitoring of the wastewater processes.

Software Specifications

In addition to the hardware components, specialized software is necessary to configure and manage Ethernet/IP systems in wastewater applications. These software specifications provide operators with the tools they need to optimize system performance and gain valuable insights for efficient decision-making:

1. Device Configuration Software: Device configuration software allows operators to set up and customize the parameters of Ethernet/IP devices in the wastewater system. This software provides a user-friendly interface to configure network settings, assign IP addresses, and define communication protocols. With device configuration software, operators can easily adapt the Ethernet/IP network to the specific requirements of the wastewater treatment process.

2. Network Management Software: Network management software plays a crucial role in monitoring and controlling the Ethernet/IP network in wastewater applications. This software provides real-time visibility into network performance, allowing operators to identify and troubleshoot issues promptly. Additionally, network management software enables the configuration of network security settings, ensuring the integrity and confidentiality of data transmitted over the Ethernet/IP network.

3. Data Analysis Software: Advanced software solutions offer data analysis capabilities, empowering operators with valuable insights for efficient decision-making in wastewater applications. With data analysis software, operators can monitor key performance indicators, detect anomalies, and identify trends in the wastewater treatment process. This information can be used to optimize system efficiency, reduce energy consumption, and improve overall operational performance.

In conclusion, implementing Ethernet/IP in wastewater applications requires a combination of hardware components and software specifications. Industrial Ethernet switches, Ethernet cables, and devices with Ethernet/IP communication capabilities form the foundation of the network, ensuring reliable and uninterrupted communication. Specialized software, such as device configuration software, network management software, and data analysis software, provides operators with the tools they need to configure, monitor, and optimize the Ethernet/IP system for efficient wastewater treatment.

Benefits of Using Ethernet/IP in Wastewater Applications

Wastewater management is a critical aspect of ensuring public health and environmental sustainability. As technology continues to advance, the integration of Ethernet/IP in wastewater applications offers numerous benefits that contribute to operational efficiency, cost-effectiveness, and enhanced data management.

Operational Efficiency

Ethernet/IP enables real-time monitoring of wastewater parameters, allowing operators to identify inefficiencies, detect faults, and optimize processes promptly. With instant access to critical data, operators can streamline operations, reduce energy consumption, and minimize costs associated with maintenance and repairs.

For example, imagine a wastewater treatment plant that utilizes Ethernet/IP to monitor the flow rate of wastewater entering the facility. By continuously monitoring this parameter, operators can identify any sudden changes or deviations from the norm, indicating a potential issue in the system. Prompt detection allows operators to take immediate action, preventing any further damage or disruption to the treatment process.

In addition to flow rate monitoring, Ethernet/IP can also be utilized to monitor other crucial parameters such as pH levels, dissolved oxygen levels, and turbidity. By having real-time access to this data, operators can make informed decisions regarding the addition of chemicals or adjustments to the treatment process, ensuring optimal efficiency.

Cost-Effectiveness

By leveraging Ethernet/IP technology, wastewater management systems can reduce costs associated with manual data collection, troubleshooting, and downtime. With remote access to equipment, operators can diagnose and resolve issues without the need for physical presence, saving valuable time and resources.

Consider a scenario where a wastewater treatment plant experiences a sudden equipment failure. In a traditional setup, operators would need to physically inspect the equipment, potentially causing significant downtime and incurring additional costs. However, with Ethernet/IP, operators can remotely access the equipment's diagnostic data, pinpoint the cause of the failure, and even perform troubleshooting steps remotely. This capability minimizes downtime, reduces the need for on-site maintenance personnel, and ultimately leads to cost savings.

Furthermore, Ethernet/IP allows for predictive maintenance strategies. By continuously monitoring equipment performance and analyzing historical data, operators can identify potential issues before they escalate into costly failures. This proactive approach to maintenance helps optimize equipment lifespan, reduce repair costs, and minimize unplanned downtime.

Enhanced Data Management

Ethernet/IP facilitates centralized data management, allowing operators to store, organize, and analyze vast amounts of data generated by wastewater applications. With the ability to access historical data and track trends, operators can make informed decisions, optimize processes, and ensure compliance with regulatory standards.

For instance, imagine a wastewater treatment plant that needs to report its effluent quality to regulatory authorities regularly. With Ethernet/IP, operators can easily retrieve historical data on various water quality parameters, such as biochemical oxygen demand (BOD) and total suspended solids (TSS). This data can then be analyzed to identify trends, assess compliance with regulatory limits, and make any necessary process adjustments to maintain water quality standards.

In addition to regulatory compliance, Ethernet/IP also enables operators to leverage data analytics tools to gain valuable insights. By analyzing historical data, operators can identify patterns, correlations, and potential areas for improvement. This data-driven approach empowers operators to optimize processes, reduce energy consumption, and minimize the environmental impact of wastewater treatment.

Overall, the integration of Ethernet/IP in wastewater applications offers significant advantages in terms of operational efficiency, cost-effectiveness, and enhanced data management. By harnessing the power of real-time monitoring, remote access, and centralized data storage, operators can ensure optimal performance, reduce costs, and make informed decisions to meet the challenges of wastewater management effectively.

Setting Up Ethernet/IP for Wastewater Applications

Setting up Ethernet/IP in wastewater applications involves several steps. First, ensure that all the necessary hardware components, such as Ethernet switches, cables, and devices, are available and properly installed. This includes selecting switches with sufficient port capacity to accommodate the desired number of devices in the network. It is also important to choose cables that meet the required specifications for Ethernet/IP communication, such as Cat5e or Cat6 cables.

Next, configure the Ethernet/IP network by assigning IP addresses to devices and establishing communication parameters. This can be done through the use of software tools provided by the equipment manufacturers or through the device's web interface. It is essential to assign unique IP addresses to each device to avoid conflicts and ensure proper communication. Additionally, setting up subnet masks and default gateways correctly is crucial for smooth data exchange.

Once the hardware and network configuration are in place, it is time to test the connectivity. This involves verifying that all devices can communicate with each other and exchange data seamlessly. Various diagnostic tools, such as ping tests or network analyzers, can be used to ensure proper connectivity. It is also important to check for any latency or packet loss issues that may affect the performance of the Ethernet/IP network.

Troubleshooting Common Issues

While Ethernet/IP offers reliable communication, occasional issues may arise. One common problem is network connectivity disruptions. These disruptions can be caused by factors such as faulty cables, loose connections, or power outages. Troubleshooting these issues often involves physically inspecting the cables and connections, ensuring they are securely plugged in and free from damage. In the case of power outages, it may be necessary to check the power supply to the Ethernet switches and devices.

Incompatible firmware versions can also cause communication problems in Ethernet/IP networks. It is important to keep the firmware of all devices up to date and ensure compatibility between different devices. Manufacturers often release firmware updates that address known issues and improve overall performance. Updating firmware can be done through the manufacturer's software tools or by following specific instructions provided in the device's manual.

Configuration errors can also lead to communication issues in Ethernet/IP networks. These errors can include incorrect IP address assignments, subnet mask settings, or gateway configurations. Troubleshooting configuration errors often involves double-checking the settings of each device and comparing them to the recommended configurations provided by the manufacturer. It is advisable to consult the device manuals or contact technical support for guidance in resolving configuration-related issues.

In conclusion, setting up Ethernet/IP for wastewater applications requires careful consideration of hardware components, proper network configuration, and thorough testing of connectivity. Troubleshooting common issues, such as network disruptions, incompatible firmware versions, or configuration errors, is essential for maintaining smooth and reliable communication in Ethernet/IP networks.

Maintaining and Optimizing Ethernet/IP Systems

When it comes to maintaining and optimizing Ethernet/IP systems in wastewater applications, routine maintenance is crucial for ensuring long-term reliability and optimal performance. In addition to the basic maintenance tasks mentioned earlier, there are several other important aspects to consider.

Routine Maintenance Tips

Inspecting cable connections is an essential part of routine maintenance. This involves visually examining the cables for any signs of wear and tear, such as frayed wires or loose connectors. It is also important to check for proper grounding to prevent electrical interference and ensure the integrity of the system.

Monitoring network traffic is another critical aspect of routine maintenance. By regularly monitoring the network, operators can identify any abnormal patterns or excessive traffic that may indicate potential issues. This proactive approach allows for timely troubleshooting and prevents unexpected downtime.

Updating software and firmware is an ongoing task that should not be overlooked. Manufacturers often release updates to address security vulnerabilities, improve system performance, and add new features. By keeping the software and firmware up to date, operators can take advantage of these enhancements and ensure the system operates at its best.

Periodic calibration and verification of sensors and instruments are necessary for accurate data acquisition. Over time, sensors may drift or become less accurate, leading to unreliable measurements. By calibrating and verifying these devices, operators can maintain the integrity of the data collected, which is crucial for making informed decisions and optimizing the system.

System Optimization Techniques

In addition to routine maintenance, there are various techniques that operators can implement to optimize Ethernet/IP systems in wastewater applications.

One such technique is network segmentation. By dividing the network into smaller segments, operators can enhance data security and improve network performance. This segmentation helps isolate critical systems and sensitive data, reducing the risk of unauthorized access or data breaches. It also allows for better control over network traffic and facilitates easier troubleshooting.

Implementing redundancy measures is another important optimization technique. Redundancy ensures uninterrupted communication by providing backup components or alternative pathways in case of failures. This can include redundant switches, power supplies, or even redundant network paths. By having redundant systems in place, operators can minimize downtime and maintain continuous operation, even in the event of a failure.

Conducting periodic network performance assessments is also crucial for optimization. By regularly evaluating the network's performance, operators can identify potential bottlenecks or areas for improvement. This assessment may involve analyzing network traffic, measuring latency, or conducting stress tests to simulate heavy usage scenarios. The insights gained from these assessments can help operators make informed decisions to optimize the system's performance and ensure it meets the demands of the wastewater application.

In conclusion, maintaining and optimizing Ethernet/IP systems in wastewater applications requires a combination of routine maintenance and optimization techniques. By following these tips and implementing the suggested techniques, operators can ensure the long-term reliability, performance, and security of their Ethernet/IP systems.

Future Trends in Ethernet/IP for Wastewater Management

Technological Advancements

Ethernet/IP technology continues to evolve, and future advancements are expected to enhance its capabilities in wastewater management. These may include improved interoperability between devices, increased data transmission speeds, and enhanced cybersecurity measures to safeguard critical infrastructure from cyber threats.

Regulatory Impacts

The evolving landscape of wastewater regulations will likely influence the adoption and usage of Ethernet/IP systems. Regulatory bodies may impose stricter standards on data monitoring and reporting, driving the need for more advanced and compliant Ethernet/IP solutions. Adapting to these regulatory changes will be crucial for wastewater management organizations.

Conclusion: The Impact of Ethernet/IP on Wastewater Management

Ethernet/IP has become an indispensable tool for wastewater management applications, offering seamless connectivity, real-time monitoring, and enhanced data management capabilities. With its ability to optimize operations, reduce costs, and ensure regulatory compliance, Ethernet/IP is transforming the way wastewater is managed. As this technology continues to evolve, wastewater management organizations must stay abreast of the latest advancements and leverage Ethernet/IP to achieve operational excellence and environmental stewardship.