Grit Chamber: Wastewater Treatment Explained

In the complex world of wastewater treatment, the grit chamber plays a crucial role. This component of the treatment process is designed to remove grit, such as sand, gravel, and other small, heavy solids, from the wastewater stream. These materials, if not removed, can cause significant damage to downstream processes and equipment. This article will delve into the intricate details of the grit chamber, its functions, types, design considerations, and importance in the overall wastewater treatment process.

Understanding the Role of a Grit Chamber

The primary function of a grit chamber is to protect the mechanical equipment in a wastewater treatment plant from potential damage caused by grit. Grit, in the context of wastewater treatment, refers to inorganic solids such as sand, gravel, eggshells, bone chips, seeds, and other similar materials. These substances are heavier than organic biodegradable solids present in wastewater and hence can be separated out effectively in a grit chamber.

Without a grit chamber, these materials would continue through the treatment process, causing wear and tear on mechanical equipment, clogging pipes and channels, and negatively impacting the efficiency of subsequent treatment processes. The removal of grit at an early stage of treatment, therefore, is crucial to maintaining the longevity and efficiency of a wastewater treatment plant.

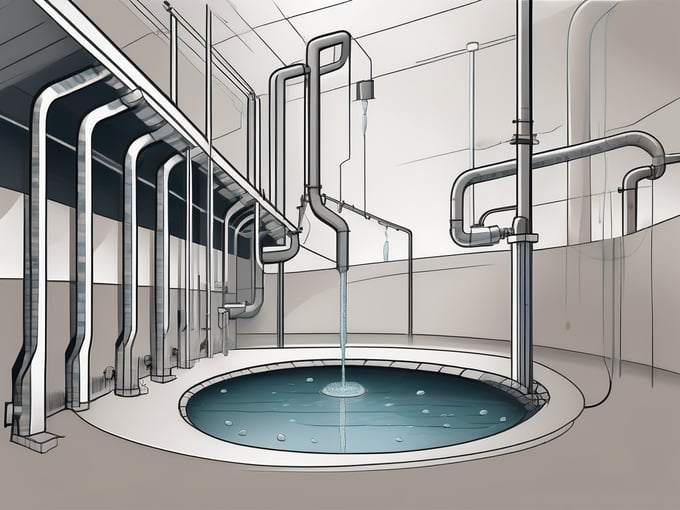

How a Grit Chamber Works

A grit chamber operates on the principle of sedimentation. Wastewater entering the chamber is slowed down, allowing heavier grit particles to settle at the bottom due to gravity. The settled grit is then collected and removed from the chamber, while the grit-free wastewater continues on to the next stage of treatment.

The effectiveness of a grit chamber in removing grit depends on several factors, including the size and specific gravity of the grit particles, the flow rate of the wastewater, and the design of the chamber. These factors must be carefully considered during the design and operation of a grit chamber to ensure optimal performance.

Types of Grit Chambers

There are several types of grit chambers used in wastewater treatment, each with its own advantages and disadvantages. The choice of grit chamber type depends on the specific requirements of the treatment plant, including the characteristics of the incoming wastewater, the available space, and the budget.

The two main types of grit chambers are horizontal flow grit chambers and aerated grit chambers. Other types include vortex grit chambers and inclined grit chambers. Each of these types will be discussed in detail in the following sections.

Horizontal Flow Grit Chambers

Horizontal flow grit chambers are the simplest and most common type of grit chamber. They consist of a rectangular tank in which the wastewater flows horizontally, allowing grit to settle at the bottom. The settled grit is then removed by a mechanical scraper or manually.

These chambers are easy to construct and operate, but their efficiency in removing grit can be affected by variations in the flow rate of the wastewater. They also require a large space and may not be suitable for treatment plants with limited space.

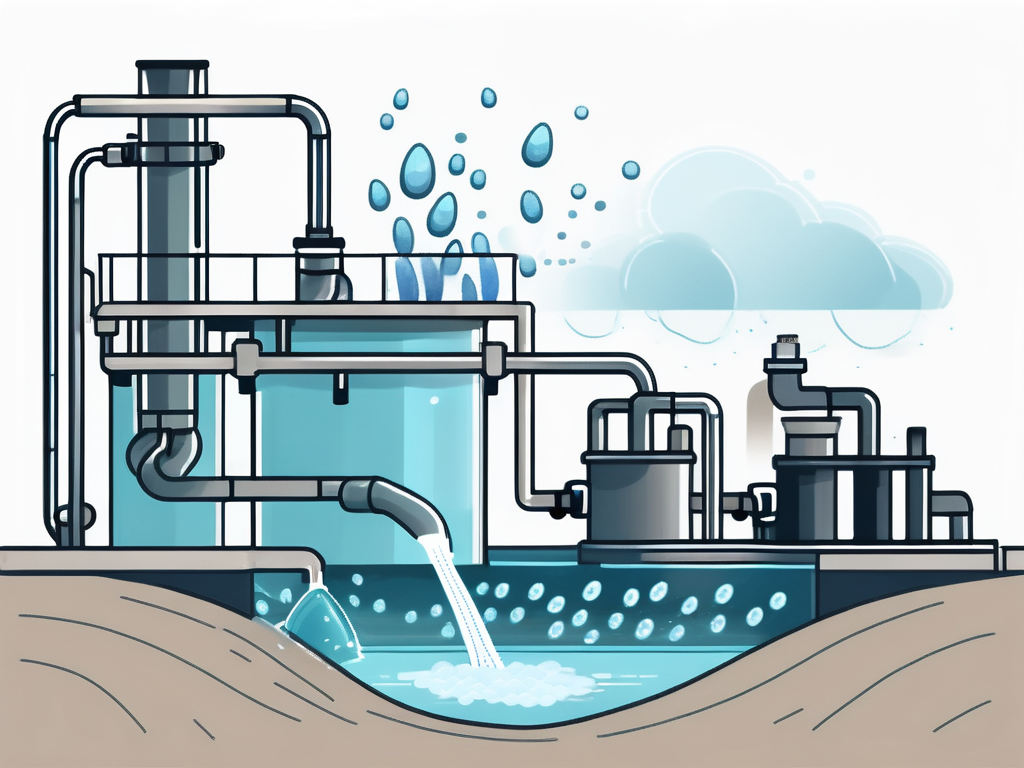

Aerated Grit Chambers

Aerated grit chambers use air to create a spiral flow pattern in the wastewater. This causes the grit to move towards the center of the chamber, where it settles and is removed. The use of air also helps to keep organic matter suspended in the wastewater, preventing it from settling with the grit.

These chambers are more efficient in removing grit than horizontal flow grit chambers, especially for smaller grit particles. However, they are more complex to design and operate, and they require more energy due to the need for aeration.

Design Considerations for Grit Chambers

The design of a grit chamber is a critical aspect of its performance. Several factors must be considered in the design process, including the characteristics of the incoming wastewater, the desired removal efficiency, the available space, and the budget.

The size of the grit chamber is determined based on the flow rate of the wastewater and the desired detention time. The detention time is the time that the wastewater spends in the chamber, which should be long enough to allow the grit to settle but not so long that organic matter also settles. The shape of the chamber, the method of grit removal, and the aeration system (if applicable) are also important design considerations.

Designing for Optimal Performance

To achieve optimal performance, a grit chamber must be designed to effectively remove grit without removing too much organic matter. This requires a delicate balance between the flow rate of the wastewater, the detention time, and the settling velocity of the grit particles.

The design should also take into account the variations in the characteristics of the incoming wastewater, such as the grit load and the flow rate, which can vary with time and weather conditions. The design should be flexible enough to handle these variations without compromising the performance of the chamber.

Designing for Ease of Maintenance

Another important consideration in the design of a grit chamber is ease of maintenance. The chamber should be designed in such a way that the settled grit can be easily and efficiently removed. This may involve the use of mechanical equipment, such as scrapers or pumps, which should be easy to access and maintain.

The chamber should also be designed to minimize the accumulation of grit in corners or dead zones, which can be difficult to remove and can lead to operational problems. The materials used in the construction of the chamber should be resistant to corrosion and abrasion caused by the grit and the wastewater.

Importance of Grit Chambers in Wastewater Treatment

Grit chambers play a vital role in the wastewater treatment process. By removing grit at an early stage of treatment, they protect the mechanical equipment in the treatment plant from damage, reduce maintenance costs, and improve the efficiency of subsequent treatment processes.

Despite their importance, grit chambers are often overlooked or underestimated in the design and operation of wastewater treatment plants. A well-designed and properly operated grit chamber can significantly enhance the performance and longevity of a wastewater treatment plant, making it a critical component of the treatment process.

The Impact of Grit on Wastewater Treatment

Grit can have a significant impact on the performance and cost of wastewater treatment. It can cause wear and tear on mechanical equipment, leading to increased maintenance and replacement costs. It can also clog pipes and channels, reducing the capacity of the treatment plant and leading to operational problems.

Furthermore, if grit is not removed effectively, it can settle in biological treatment units, reducing their efficiency and requiring costly and disruptive cleaning operations. Therefore, the removal of grit is a critical step in the wastewater treatment process.

The Benefits of Effective Grit Removal

Effective grit removal can bring several benefits to a wastewater treatment plant. It can extend the lifespan of mechanical equipment, reduce maintenance costs, improve the efficiency of biological treatment processes, and prevent operational problems caused by clogged pipes and channels.

Moreover, the grit removed from the wastewater can be treated and disposed of safely, reducing the environmental impact of the treatment process. In some cases, it can even be recycled and used for beneficial purposes, such as road construction or landfill cover.

Conclusion

The grit chamber is a critical component of the wastewater treatment process. It serves to protect the mechanical equipment in the treatment plant from damage caused by grit, thereby reducing maintenance costs and improving the efficiency of the treatment process.

Despite its importance, the design and operation of a grit chamber require careful consideration and expertise. The characteristics of the incoming wastewater, the desired removal efficiency, the available space, and the budget are all factors that must be taken into account. With a well-designed and properly operated grit chamber, a wastewater treatment plant can achieve optimal performance and longevity.