Fundamentals of Hart

In the complex world of industrial automation, the Highway Addressable Remote Transducer (HART) protocol has emerged as a leading standard. This digital communication protocol is widely used in industrial automation for data exchange between smart field devices and control systems. Offering a unique blend of digital and analog communication, HART provides a reliable, long-standing solution for industrial communication needs.

Understanding the HART Protocol

At its core, the HART protocol is a communication method that allows digital and analog signals to coexist. This unique feature enables it to maintain compatibility with older, analog-only devices while providing the benefits of digital communication. The protocol uses the Frequency Shift Keying (FSK) standard to superimpose digital communication signals on the conventional 4-20mA analog signal.

What sets HART apart is its ability to communicate over legacy 4-20mA analog wiring, making it an ideal choice for upgrading existing facilities without the need for extensive rewiring. This backward compatibility, coupled with its ability to deliver digital data, has made HART a popular choice in many industries, including oil and gas, chemical, and process control.

Key Features of the HART Protocol

Simultaneous Analog and Digital Communication

One of the defining features of the HART protocol is its ability to carry out simultaneous analog and digital communication. This means that while the 4-20mA analog signal can carry process variables (like pressure, temperature, flow rate), the digital signal can carry additional device-specific information, such as device status, diagnostics, and additional process variables.

This dual communication capability allows for richer data communication and more sophisticated device management, making HART-enabled devices smarter and more versatile than their analog-only counterparts.

Backward Compatibility

Another significant advantage of the HART protocol is its backward compatibility. Because HART communicates using the existing 4-20mA signal, it can work with legacy systems that are designed for analog signals. This means that facilities can upgrade to HART-enabled devices without the need for extensive system overhauls or rewiring.

Moreover, HART's backward compatibility extends to the device level. This means that HART-enabled devices can communicate with non-HART devices, making the transition to a HART-based system smoother and more cost-effective.

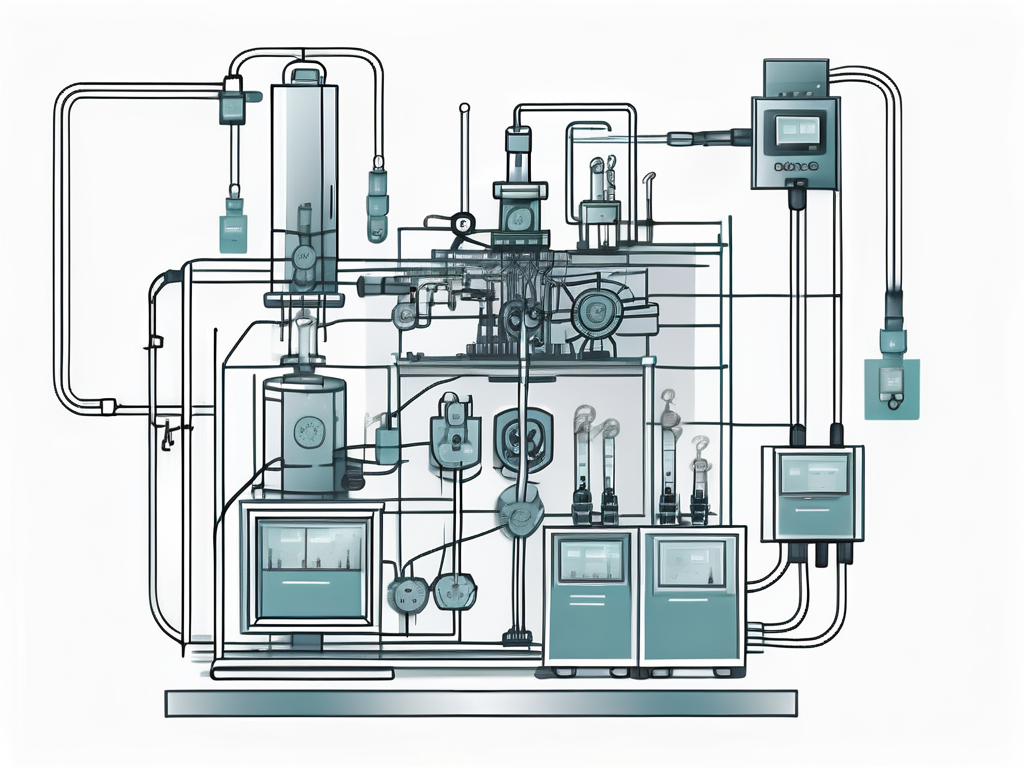

How the HART Protocol Works

The HART protocol operates by superimposing digital communication signals onto the existing 4-20mA analog signal. This is achieved using the Frequency Shift Keying (FSK) standard, where two different frequencies represent binary 0 and 1. The digital signal is a low-level signal that does not interfere with the analog signal, allowing both to coexist on the same wire.

The digital communication in HART includes both a command and a response. The command is sent from the control system (like a PLC or DCS) to the field device, instructing it to perform a specific action or return specific data. The field device then responds with the requested data or an acknowledgment.

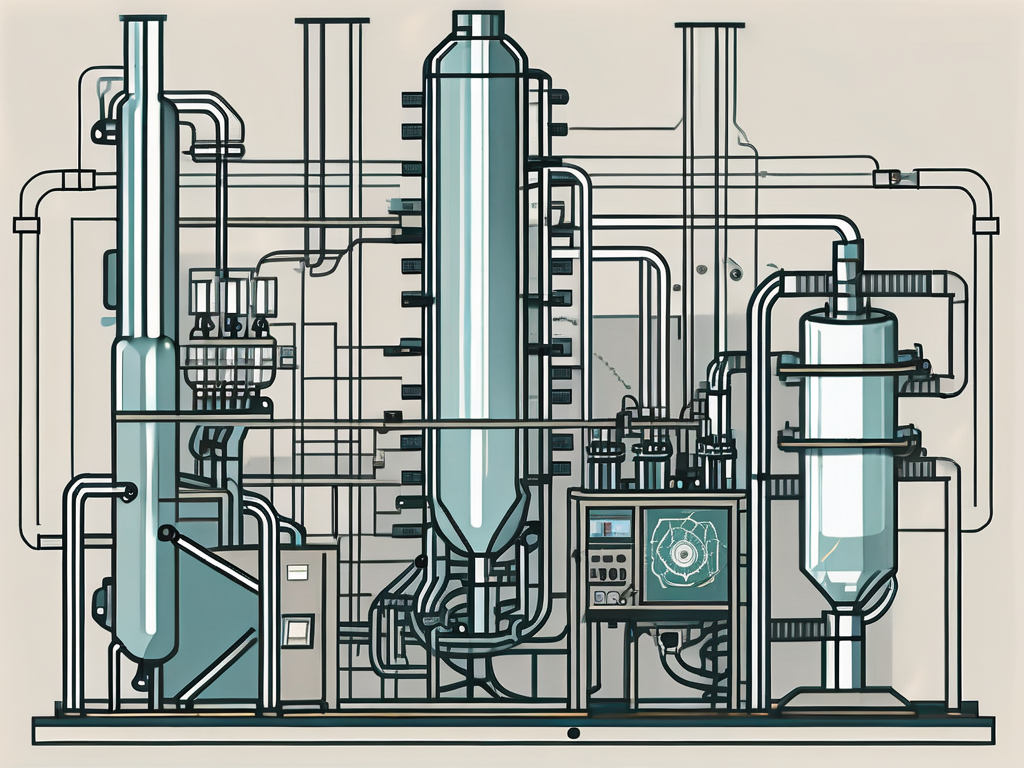

Applications of the HART Protocol

The HART protocol finds wide application in various industries due to its unique features and benefits. In the oil and gas industry, for instance, HART is used for remote monitoring and control of field devices, providing real-time data for efficient operation and maintenance.

In the chemical industry, HART enables sophisticated process control by allowing for the simultaneous communication of multiple process variables. This enables more accurate control and monitoring, leading to improved product quality and safety.

Overall, the HART protocol has proven to be a reliable, versatile, and cost-effective solution for industrial communication. Its unique blend of analog and digital communication, coupled with its backward compatibility, makes it an ideal choice for both new installations and upgrades of existing systems.