Fundamentals of Honeywell SDS

In the dynamic world of industrial automation, protocols play a pivotal role in ensuring seamless communication between devices. One such protocol that has been instrumental in shaping the industry is the Honeywell SDS (Smart Distributed System). This robust, high-speed, and flexible protocol is designed to meet the demanding requirements of industrial environments.

Understanding Honeywell SDS

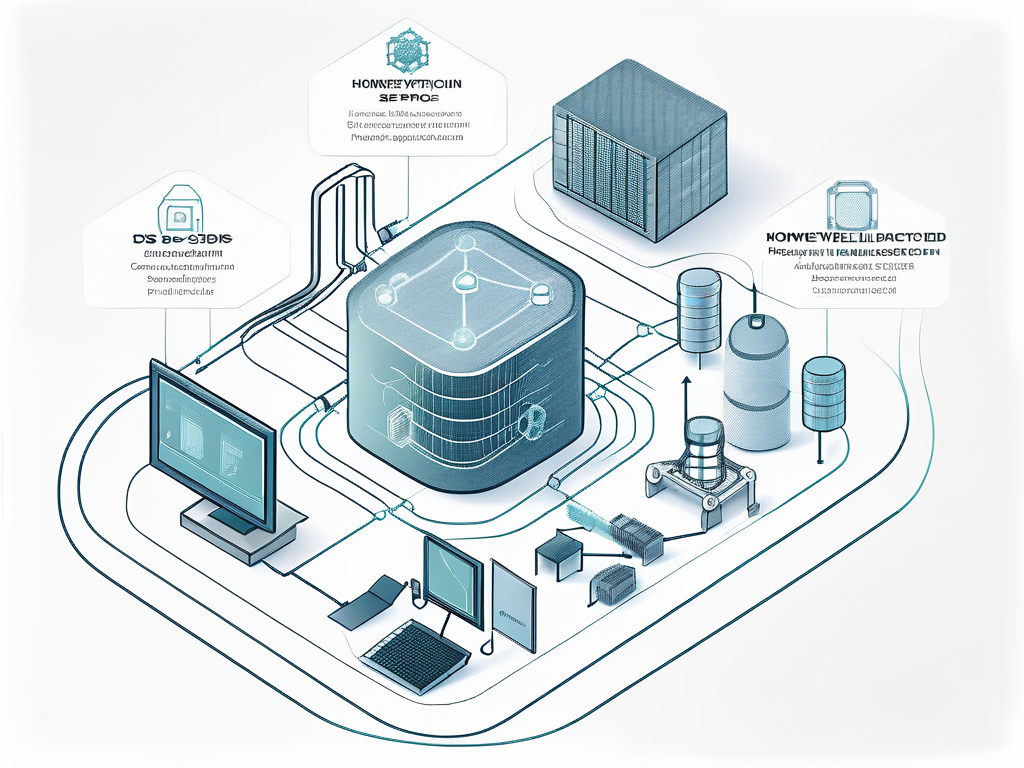

The Honeywell SDS is a proprietary communications protocol developed by Honeywell. It is designed to facilitate communication between smart devices in distributed control systems. The protocol is known for its high-speed data transfer and real-time capabilities, making it ideal for industrial applications where timing is critical.

SDS supports a wide range of devices, including sensors, actuators, and controllers. It provides a common language for these devices to communicate, enabling them to share data and work together effectively. This interoperability is a key advantage of Honeywell SDS, as it allows for a more integrated and efficient system.

The Architecture of Honeywell SDS

The architecture of Honeywell SDS is based on a distributed model, where each device on the network has its own intelligence. This means that devices can operate independently and make decisions without the need for a central controller. This distributed intelligence helps to improve the reliability and efficiency of the system.

The SDS network is structured as a series of nodes, each of which represents a device on the network. These nodes communicate with each other using the SDS protocol, exchanging data and commands. The network can support up to 64 nodes, providing ample capacity for even large-scale industrial systems.

Key Features of Honeywell SDS

Honeywell SDS boasts several features that set it apart from other industrial protocols. These include its high-speed data transfer, real-time capabilities, and distributed intelligence. Let's delve into these features in more detail.

High-speed data transfer is a hallmark of Honeywell SDS. The protocol can support data rates up to 1 Mbps, which is significantly faster than many other industrial protocols. This high-speed communication allows for real-time control of devices, which is crucial in many industrial applications.

Real-Time Capabilities

The real-time capabilities of Honeywell SDS are another standout feature. The protocol is designed to provide consistent and predictable communication, regardless of network load. This ensures that data is always delivered in a timely manner, which is critical for real-time control and monitoring.

Furthermore, Honeywell SDS supports deterministic data transfer. This means that the time it takes for data to travel from one device to another is known and predictable, which is essential for real-time applications.

Distributed Intelligence

The distributed intelligence of Honeywell SDS is a key feature that enhances the efficiency and reliability of the system. By allowing devices to operate independently and make decisions on their own, the system can continue to function even if one device fails. This redundancy helps to ensure that the system is always up and running, minimizing downtime and improving productivity.

Moreover, distributed intelligence allows for more flexible system design. Devices can be added or removed from the network without disrupting the entire system, making it easier to scale and adapt the system as needed.

Applications of Honeywell SDS

Honeywell SDS is used in a wide range of industrial applications, thanks to its robust features and capabilities. Some of the key areas where it is used include process control, factory automation, and building management systems.

In process control, Honeywell SDS is used to manage and control various processes in industries such as chemical, oil and gas, and power generation. Its high-speed data transfer and real-time capabilities make it ideal for these applications, where precise control and timely data are critical.

Factory Automation

In factory automation, Honeywell SDS is used to control and monitor machinery and equipment. Its distributed intelligence allows for more efficient operation, as devices can make decisions on their own without the need for a central controller. This can help to improve productivity and reduce downtime.

Furthermore, the flexibility of Honeywell SDS makes it suitable for a wide range of factory automation applications. Whether it's controlling a single machine or coordinating a complex production line, Honeywell SDS can handle it.

Building Management Systems

Honeywell SDS is also used in building management systems to control and monitor various building functions. These include heating, ventilation, and air conditioning (HVAC), lighting, and security systems. The protocol's high-speed data transfer and real-time capabilities ensure that these systems operate efficiently and effectively.

In conclusion, Honeywell SDS is a powerful industrial protocol that offers a host of benefits for a wide range of applications. Its high-speed data transfer, real-time capabilities, and distributed intelligence make it a reliable and efficient choice for industrial automation. Whether you're looking to improve process control, enhance factory automation, or optimize building management systems, Honeywell SDS has you covered.