Fundamentals of SERCOS III

In the realm of industrial automation, SERCOS III (Serial Real-time Communication System) has emerged as a leading protocol. It is a digital motion control bus that facilitates high-speed serial communication between controls, drives, I/O, and sensors. This article delves into the fundamentals of SERCOS III, its architecture, benefits, and applications, providing a comprehensive understanding of this crucial industrial protocol.

Understanding SERCOS III

SERCOS III is the third generation of the SERCOS interface, an open protocol for digital communication in automation technology. It was developed and standardized by the SERCOS International e.V organization, which is a consortium of various companies and institutions worldwide. SERCOS III is designed to facilitate real-time communication in highly demanding applications, particularly in machine and plant engineering.

The protocol is based on Ethernet, which allows for the integration of various automation devices into a single network. It supports both hard and soft real-time requirements, making it suitable for a wide range of applications. SERCOS III is also characterized by its high data transfer rate and deterministic behavior, which are essential for high-performance automation systems.

Architecture of SERCOS III

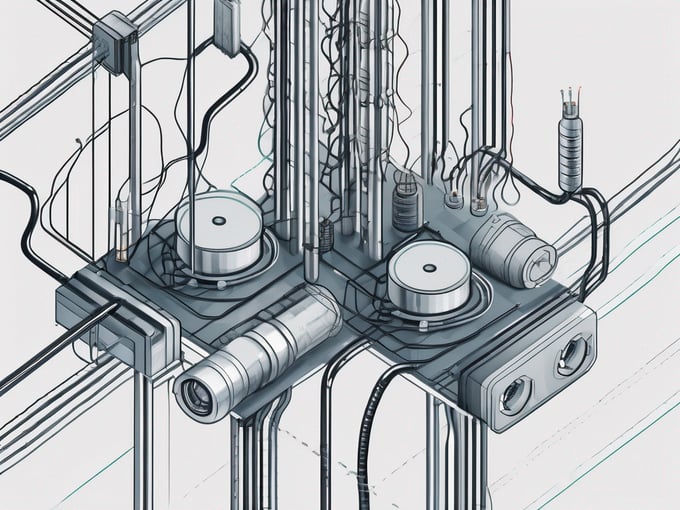

The architecture of SERCOS III is designed to ensure efficient and reliable communication in industrial environments. It is based on a ring topology, which provides redundancy and ensures uninterrupted operation even in the event of a device failure. The protocol uses a master-slave configuration, where the master (usually a control unit) initiates communication and the slaves (drives, I/O devices, etc.) respond.

The communication process in SERCOS III is divided into phases, each with a specific function. The phases include the Initialization Phase, Parameter Phase, and Communication Phase. This structured approach ensures that all devices are properly configured and synchronized before data exchange begins.

Initialization Phase

In the Initialization Phase, the master identifies all the slaves in the network and assigns them unique addresses. This phase also involves checking the status of each slave and ensuring that they are ready for operation.

Parameter Phase

The Parameter Phase involves the configuration of the slaves based on the requirements of the application. This includes setting parameters such as the communication cycle time, the synchronization mode, and the data exchange format.

Communication Phase

The Communication Phase is where the actual data exchange occurs. The master sends commands to the slaves, and the slaves respond with their status and data. The communication is deterministic, meaning that it occurs at predictable intervals, ensuring real-time performance.

Benefits of SERCOS III

SERCOS III offers several benefits that make it a preferred choice for many industrial applications. One of its key advantages is its high-speed communication. With a data transfer rate of up to 100 Mbit/s, SERCOS III can handle large amounts of data quickly and efficiently. This is particularly beneficial in applications that require high-speed motion control.

Another significant benefit of SERCOS III is its deterministic behavior. This ensures that communication occurs at predictable intervals, which is crucial for real-time applications. Furthermore, the protocol's ring topology provides redundancy, ensuring uninterrupted operation even if a device fails.

SERCOS III also offers flexibility in terms of device integration. Since it is based on Ethernet, it can integrate various automation devices into a single network. This simplifies network design and reduces the cost and complexity of system integration.

Applications of SERCOS III

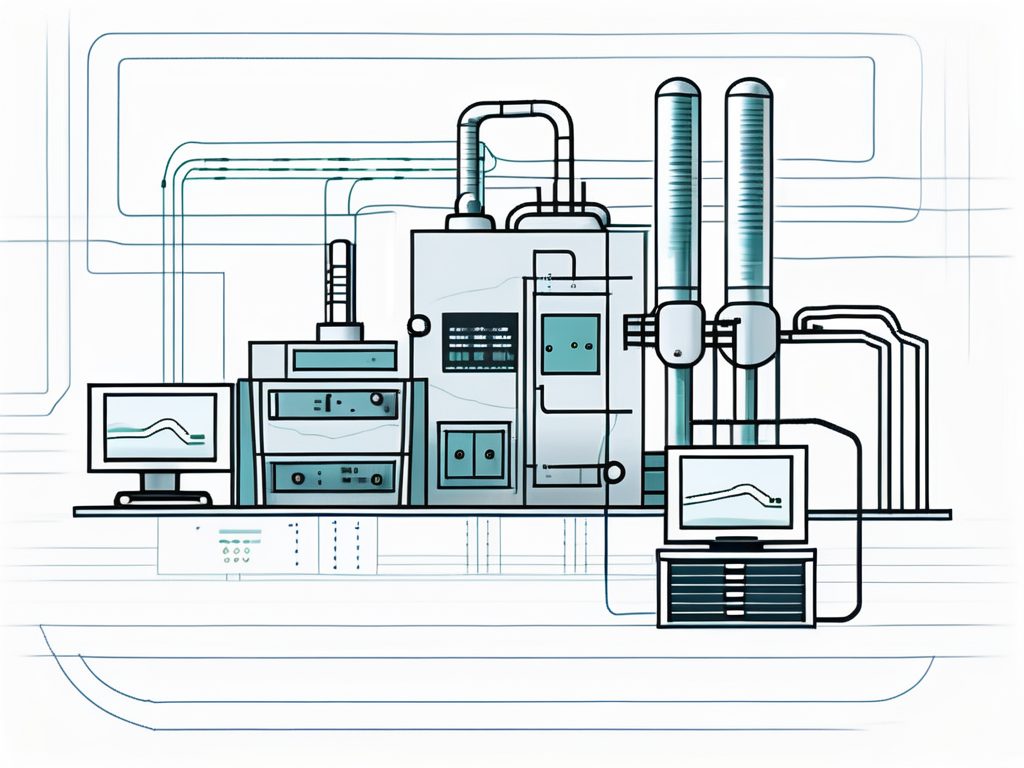

SERCOS III is used in a wide range of applications, particularly in machine and plant engineering. Its high-speed, deterministic communication makes it suitable for applications that require precise motion control, such as CNC machines, robotics, and packaging machines.

Furthermore, the protocol's flexibility and ease of integration make it a preferred choice for complex automation systems. For instance, it is used in production lines that involve multiple machines and processes, where efficient coordination and synchronization are crucial.

In conclusion, SERCOS III is a powerful industrial protocol that offers high-speed, deterministic communication for a wide range of applications. Its flexible architecture, ease of integration, and robust performance make it a preferred choice for many industrial automation systems. As the demand for efficient and reliable communication continues to grow, the importance of understanding and implementing SERCOS III will only increase.