Industrial Wastewater: Wastewater Treatment Explained

Industrial wastewater treatment refers to the processes used to treat water that has been contaminated by anthropogenic industrial or commercial activities prior to its release into the environment or its re-use. These activities produce wastewater that can cause pollution. It is crucial to treat this water to reduce the harm caused to the environment when it is released.

Most industries produce some form of wastewater, and the increase in industrial activity worldwide has led to serious water pollution issues. The nature and characteristics of the wastewater vary depending on the type of industry, which makes industrial wastewater treatment a complex and challenging issue.

Types of Industrial Wastewater

Industrial wastewater can be categorized into two main types: process wastewater and cooling water. Process wastewater is water that comes into contact with any raw material, product, byproduct, or waste during manufacturing. Cooling water is used in industrial processes to regulate temperature and does not come into contact with any raw materials or products.

Each type of industrial wastewater has its own unique characteristics and requires a different treatment approach. The type of wastewater produced depends on the industry. For example, the food and beverage industry generates wastewater that is high in organic material, while the metal industry produces wastewater that contains heavy metals.

Process Wastewater

Process wastewater is typically more challenging to treat than cooling water because it contains a wide variety of pollutants. These can include organic and inorganic materials, heavy metals, pathogens, and other harmful substances. The treatment of process wastewater often involves several stages, including preliminary treatment, primary treatment, secondary treatment, and tertiary or advanced treatment.

The specific treatment processes used can vary widely depending on the nature of the pollutants in the wastewater. However, common treatment methods include sedimentation, biological treatment, chemical treatment, and physical processes such as filtration and flotation.

Cooling Water

While cooling water does not come into direct contact with raw materials or products, it can still become contaminated during use. This can occur through the accumulation of minerals, the growth of microorganisms, or the addition of chemicals used to prevent these issues.

Treatment of cooling water typically involves the use of chemical additives to control scaling, corrosion, and biological growth. In addition, cooling water may be treated through physical processes such as filtration to remove particulates, or through thermal processes to reduce the concentration of dissolved solids.

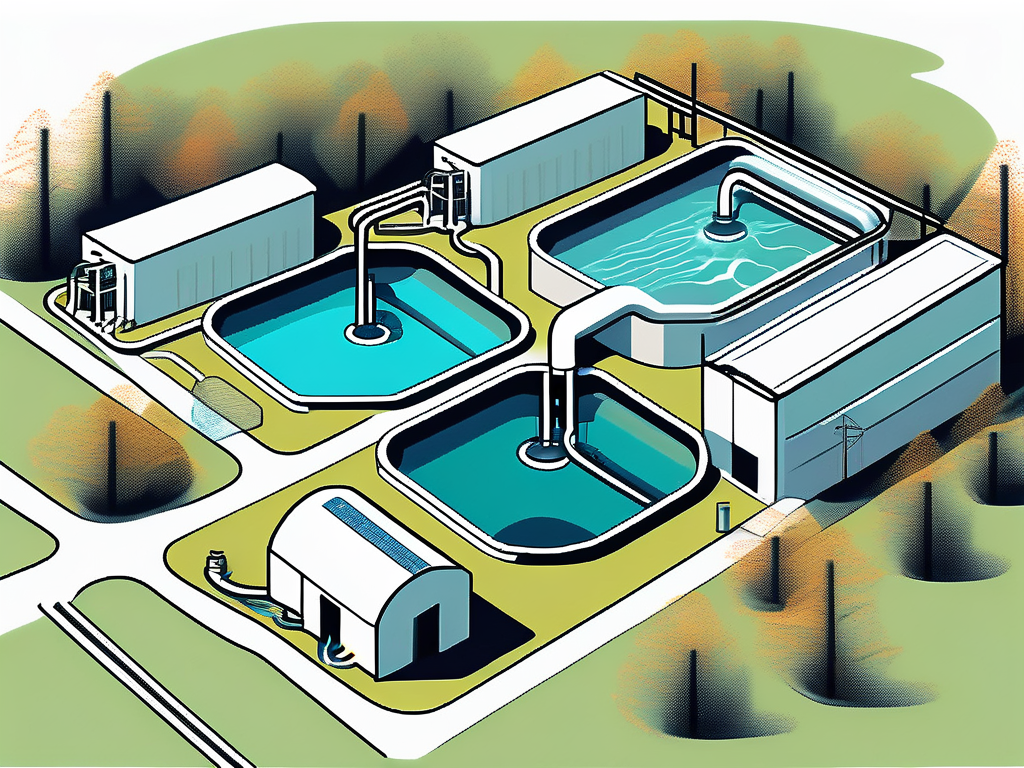

Stages of Industrial Wastewater Treatment

Industrial wastewater treatment typically involves several stages, each designed to remove or reduce a specific type of pollutant. The exact sequence and nature of these stages can vary widely depending on the characteristics of the wastewater and the requirements for its discharge or reuse.

However, a typical treatment sequence might include preliminary treatment, primary treatment, secondary treatment, and tertiary or advanced treatment. Each of these stages involves different treatment processes, and each is designed to deal with different types of pollutants.

Preliminary Treatment

The purpose of preliminary treatment is to remove large particles and other materials that could damage or interfere with subsequent treatment processes. This can include the removal of grit, trash, and debris, as well as the adjustment of pH and the reduction of oil and grease levels.

Common preliminary treatment processes include screening, grit removal, and equalization. Screening involves passing the wastewater through screens to remove large particles. Grit removal involves the use of sedimentation tanks to remove sand, gravel, and other heavy particles. Equalization involves the use of tanks to mix the wastewater and even out variations in flow and composition.

Primary Treatment

Primary treatment involves the removal of suspended solids and organic material from the wastewater. This is typically achieved through the use of sedimentation tanks, where the wastewater is allowed to sit and solids can settle out.

In addition to sedimentation, primary treatment can also involve the use of physical processes such as flotation, where air is bubbled through the wastewater to remove lighter particles. Chemical processes can also be used, such as coagulation and flocculation, where chemicals are added to the wastewater to cause particles to clump together and settle out.

Secondary Treatment

Secondary treatment is designed to further reduce the level of organic material in the wastewater, as well as to remove dissolved and colloidal solids. This is typically achieved through biological treatment processes, where microorganisms are used to consume organic material in the wastewater.

There are several types of biological treatment processes, including activated sludge processes, trickling filters, and lagoons. These processes all rely on the growth of microorganisms to consume organic material, but they differ in the way the microorganisms are maintained and the conditions under which they operate.

Tertiary or Advanced Treatment

Tertiary or advanced treatment is used to further improve the quality of the wastewater before it is discharged or reused. This can involve the removal of nutrients such as nitrogen and phosphorus, the removal of residual suspended solids, and the disinfection of the wastewater to kill any remaining pathogens.

There are many different types of tertiary treatment processes, including filtration, membrane processes, and advanced oxidation processes. The specific processes used depend on the quality of the wastewater after secondary treatment and the requirements for discharge or reuse.

Challenges in Industrial Wastewater Treatment

Industrial wastewater treatment presents a number of challenges. These include the wide variety of pollutants that can be present in industrial wastewater, the variability in the composition of the wastewater, and the need to meet increasingly stringent discharge standards.

In addition, industrial wastewater treatment can be expensive, and there is often a need to balance the cost of treatment with the benefits in terms of improved water quality. Finally, there is a growing recognition of the need to recover valuable resources from wastewater, such as water for reuse and nutrients for fertilizer, which adds another layer of complexity to the treatment process.

Wide Variety of Pollutants

One of the main challenges in industrial wastewater treatment is the wide variety of pollutants that can be present. These can include organic and inorganic materials, heavy metals, pathogens, and other harmful substances. Each type of pollutant requires a different treatment approach, and the presence of multiple types of pollutants can complicate the treatment process.

In addition, some pollutants can be difficult to remove from wastewater. For example, certain types of organic compounds are resistant to biological treatment and require advanced treatment processes. Similarly, heavy metals can be difficult to remove and can pose a risk to the environment if not properly treated.

Variable Composition

The composition of industrial wastewater can vary widely depending on the type of industry, the specific processes used, and other factors. This variability can make it difficult to design and operate treatment processes that are effective under all conditions.

In addition, changes in the composition of the wastewater can occur over time, due to changes in production processes, the use of different raw materials, or other factors. These changes can affect the performance of the treatment processes and require adjustments to the treatment approach.

Increasingly Stringent Discharge Standards

Regulations governing the discharge of industrial wastewater are becoming increasingly stringent, in response to growing concerns about water pollution and its impact on the environment and human health. These regulations often require the removal of specific pollutants to levels that can be difficult to achieve with conventional treatment processes.

Meeting these standards can require the use of advanced treatment processes, which can be expensive to implement and operate. In addition, the standards can vary depending on the location and the specific requirements of the regulatory authorities, adding another layer of complexity to the treatment process.

Future Trends in Industrial Wastewater Treatment

As the challenges associated with industrial wastewater treatment continue to evolve, so too do the approaches to addressing these challenges. Future trends in industrial wastewater treatment are likely to be driven by a combination of technological advances, regulatory changes, and shifts in societal attitudes towards water and the environment.

These trends include the increasing use of advanced treatment technologies, the recovery of resources from wastewater, and the integration of wastewater treatment with other aspects of industrial operations.

Advanced Treatment Technologies

Advanced treatment technologies are likely to play an increasingly important role in industrial wastewater treatment. These technologies can provide higher levels of treatment than conventional processes, enabling the removal of difficult-to-treat pollutants and the achievement of stringent discharge standards.

Examples of advanced treatment technologies include membrane processes, advanced oxidation processes, and biological nutrient removal processes. These technologies can be more expensive to implement and operate than conventional processes, but they can also provide additional benefits, such as the recovery of valuable resources from the wastewater.

Resource Recovery

The recovery of resources from wastewater is a growing trend in industrial wastewater treatment. This can include the recovery of water for reuse in industrial processes, the recovery of nutrients for use as fertilizer, and the recovery of energy from the organic material in the wastewater.

Resource recovery can provide a number of benefits, including reducing the demand for fresh water, reducing the need for synthetic fertilizers, and providing a source of renewable energy. However, it can also require the use of advanced treatment technologies and the development of markets for the recovered resources.

Integration with Industrial Operations

There is a growing recognition of the need to integrate wastewater treatment with other aspects of industrial operations. This can include the use of cleaner production techniques to reduce the generation of wastewater, the reuse of wastewater in industrial processes, and the use of wastewater treatment as a source of energy and other resources.

Integration can provide a number of benefits, including reducing the cost of wastewater treatment, improving the sustainability of industrial operations, and providing opportunities for innovation and competitive advantage. However, it can also require changes to traditional ways of doing business and the development of new skills and capabilities.

Conclusion

Industrial wastewater treatment is a complex and challenging field, but it is also one that is critical to the protection of the environment and human health. As the challenges associated with industrial wastewater treatment continue to evolve, so too do the approaches to addressing these challenges.

Future trends in industrial wastewater treatment are likely to be driven by a combination of technological advances, regulatory changes, and shifts in societal attitudes towards water and the environment. By staying abreast of these trends, industries can not only meet their regulatory obligations, but also improve their sustainability and competitiveness.