Optimizing Industrial Efficiency Through SCADA System Integration

In an increasingly competitive industrial landscape, organizations are compelled to explore innovative solutions that enhance operational efficiency. One of the most effective avenues for achieving this is through the integration of SCADA (Supervisory Control and Data Acquisition) systems. By leveraging advanced technologies to monitor and control industrial processes in real-time, SCADA systems can significantly optimize efficiency, enhance productivity, and reduce operational costs. This article delves into the various facets of SCADA system integration and its impact on industrial efficiency.

Understanding SCADA System Integration

SCADA system integration is the process of linking different components of a SCADA system to enable seamless communication and management of industrial operations. This integration allows for real-time monitoring and control of various processes, ranging from manufacturing to utilities management.

At its core, SCADA systems collect data from field devices such as sensors and PLCs (Programmable Logic Controllers), which are essential for automating industrial processes. The data is then transmitted to a central monitoring system where operators can analyze trends, detect anomalies, and make informed decisions.

Key Components of SCADA Systems

SCADA systems are composed of several key components that contribute to their efficiency and effectiveness. These components include:

- Human-Machine Interface (HMI): The interface through which operators interact with the SCADA system, visualizing data and controlling processes.

- Data Acquisition System (DAS): Hardware and software that gather data from field devices.

- Communication Infrastructure: Networking systems that enable data transfer between field devices and the central system.

- Database System: A repository for storing historical data collected by the SCADA system.

These components work in concert to provide operators with a comprehensive view of industrial processes, allowing for rapid response to any deviations from normal operations. The integration of these components not only enhances operational efficiency but also ensures that data is collected and analyzed in a timely manner, which is crucial for maintaining optimal performance across various industrial sectors.

The Role of SCADA in Industrial Automation

SCADA systems play a pivotal role in industrial automation by facilitating the management of complex processes without direct human intervention. Automating routine tasks, such as data collection, monitoring, and control, reduces the potential for human error while enabling more efficient use of resources.

Moreover, SCADA systems enhance decision-making capabilities by providing real-time insights into operations. For example, if a machine starts to exhibit extraordinary behavior due to wear and tear, the SCADA system can trigger alerts, allowing maintenance teams to intervene before a failure occurs. This proactive approach minimizes downtime and optimizes overall productivity. Additionally, SCADA systems can integrate with advanced analytics and machine learning algorithms, further enhancing their ability to predict failures and optimize performance. By analyzing historical data trends, these systems can identify patterns that may not be immediately apparent, allowing organizations to implement preventive measures and improve their operational strategies.

Furthermore, the scalability of SCADA systems means that they can adapt to the evolving needs of an organization. As industries grow and technology advances, SCADA systems can be upgraded or expanded to incorporate new devices and functionalities. This flexibility ensures that businesses can continue to leverage their SCADA systems effectively, maintaining a competitive edge in an increasingly automated world.

The Path to Industrial Efficiency

Industrial efficiency is a critical metric that organizations must address to maintain competitiveness. The pursuit of efficiency involves eliminating waste, reducing cycle times, and optimizing resource allocation. SCADA system integration is a strategic approach that aligns with these objectives.

By seamlessly integrating SCADA systems, businesses can not only streamline their operations but also enhance data visibility. This heightened transparency allows stakeholders to quickly identify inefficiencies and implement corrective measures, driving continual improvement.

The Importance of Efficiency in Industrial Settings

In today's market, the importance of efficiency in industrial settings cannot be overstated. Companies that prioritize operational efficiency can reduce costs, increase profitability, and improve customer satisfaction. Efficiency also fosters innovation, enabling organizations to allocate resources towards research and development rather than everyday operational challenges.

Efficiency, particularly in manufacturing, can significantly impact supply chain dynamics. When processes are optimized, products can be delivered faster and more reliably, gaining a competitive edge. Furthermore, an efficient organization can better adapt to market changes and consumer demands, ensuring longevity and success.

Moreover, the ripple effects of enhanced efficiency extend beyond the immediate operational framework. As organizations streamline their processes, they often find that employee morale improves as well. Workers are more engaged and motivated when they see their efforts contributing to a well-oiled machine. This can lead to lower turnover rates and a more skilled workforce, as employees feel valued and invested in the company's success.

How SCADA Systems Enhance Efficiency

SCADA systems enhance efficiency in a multitude of ways. One of the primary benefits is the ability to monitor processes in real-time. By analyzing data as it is collected, SCADA systems empower operators to make timely decisions that enhance process control.

Additionally, SCADA systems facilitate predictive maintenance by tracking equipment performance and usage. Organizations can schedule maintenance based on actual machine performance rather than adhering to a fixed schedule, thereby minimizing unnecessary downtime.

Moreover, SCADA integration can enhance energy efficiency. By monitoring energy consumption patterns and identifying areas of wastage, companies can implement strategies to optimize energy use, ultimately leading to reduced operational costs.

Furthermore, SCADA systems can integrate with other advanced technologies, such as the Internet of Things (IoT) and artificial intelligence (AI). This integration allows for even deeper insights into operational processes, enabling predictive analytics that can foresee potential issues before they arise. As a result, organizations can proactively address challenges, further enhancing their efficiency and maintaining a competitive edge in an ever-evolving industrial landscape.

The Process of SCADA System Integration

The integration of SCADA systems is not merely a technical exercise; it is a transformation process that requires careful planning and execution. Successful integration involves several key steps to ensure that the system functions effectively and meets organizational goals.

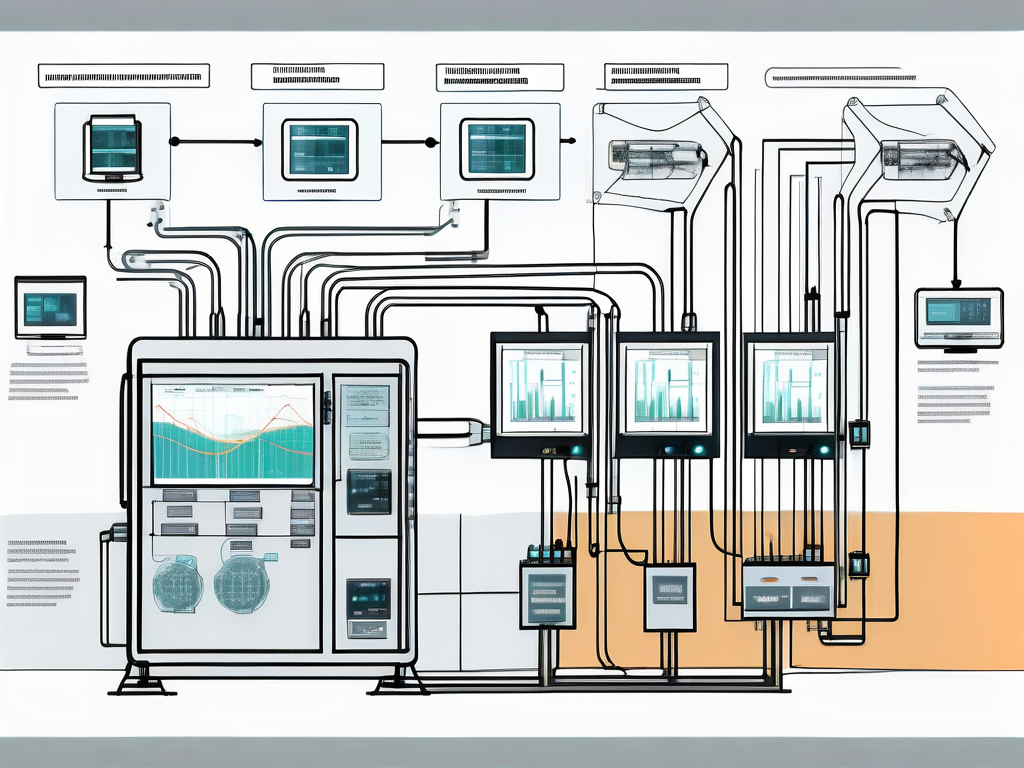

Steps in SCADA System Integration

- Assessment of Requirements: Identifying the specific needs and objectives of the integration project.

- System Design: Developing a comprehensive plan for system architecture and component integration.

- Implementation: Installing and configuring hardware and software components according to the design specifications.

- Testing: Ensuring that the integrated system functions properly, identifying and fixing any issues that arise.

- Training and Support: Providing training for users to maximize the utilization of the system and ongoing support to address concerns.

This structured approach ensures that the SCADA system not only meets current needs but also provides a robust platform for future growth and adaptation. Moreover, it allows organizations to leverage real-time data analytics and enhance operational efficiency, leading to improved decision-making processes across various levels of management.

Challenges in SCADA System Integration

While SCADA system integration offers numerous benefits, it is not without challenges. Common obstacles include compatibility issues between legacy systems and modern technologies, as well as the complexity of industrial environments.

There is also the challenge of ensuring data security. As SCADA systems become increasingly connected, vulnerabilities can expose organizations to cyber threats. Therefore, implementing rigorous security measures should be a key part of the integration process. This includes not only firewalls and intrusion detection systems but also regular audits and updates to ensure that all components are fortified against emerging threats.

Another challenge is change management. Integration might require personnel to adjust to new tools and processes, which can lead to resistance or productivity dips initially. Addressing these challenges through comprehensive training and communication strategies is essential for a smooth transition. Engaging employees early in the process and providing them with a clear understanding of the benefits of the new system can foster a more positive attitude towards the changes. Additionally, establishing feedback loops where users can voice their concerns and suggestions can help in fine-tuning the integration process, ultimately leading to a more effective and user-friendly SCADA environment.

The Impact of SCADA System Integration on Industrial Efficiency

The impact of SCADA system integration on industrial efficiency is profound. Organizations that integrate these systems often experience significant improvements in their operations.

SCADA systems enable a more proactive approach to monitoring and controlling industrial processes, allowing for faster response times and the ability to address potential issues before they escalate. These capabilities translate into reduced costs, improved quality, and enhanced customer satisfaction.

Quantifying the Benefits of SCADA System Integration

Quantifying the benefits of SCADA system integration can be achieved through various metrics. Companies can track improvements in key performance indicators (KPIs), such as production throughput, equipment downtime, and energy consumption, before and after integration.

For example, organizations might see a 15% reduction in production downtime as a result of predictive maintenance capabilities offered by SCADA systems. Additionally, energy costs may decrease by up to 20% through enhanced monitoring and management of energy consumption. Thus, organizations can make informed decisions based on tangible data to support their investment in SCADA technology.

Furthermore, the integration of SCADA systems often leads to improved workforce productivity. By automating routine tasks and providing real-time data, employees can focus on more strategic activities that drive innovation and growth. This shift not only enhances job satisfaction but also fosters a culture of continuous improvement within the organization, as teams are empowered to leverage data-driven insights to optimize processes further.

Future Trends in SCADA and Industrial Efficiency

The future of SCADA systems and their role in industrial efficiency is promising. Emerging trends such as the incorporation of artificial intelligence (AI) and machine learning are poised to revolutionize SCADA capabilities. These technologies will enable even more sophisticated predictive analytics, allowing organizations to foresee issues before they impact operations.

Moreover, the rise of IoT (Internet of Things) devices is expanding the range and granularity of data collection, leading to improved decision-making. As industries continue to adapt to evolving technologies, SCADA systems will play a critical role in ensuring that organizations not only keep pace but also thrive in their respective markets.

In addition to AI and IoT, the integration of cloud computing into SCADA systems is another trend that is gaining traction. Cloud-based SCADA solutions offer enhanced scalability and flexibility, allowing organizations to access their data and control systems from anywhere, at any time. This shift not only facilitates remote monitoring and management but also supports collaborative efforts across different locations, enabling teams to work together more effectively on complex projects. As these technologies converge, the potential for innovation and efficiency in industrial operations will only continue to grow.

Ultimately, it's clear that the integration of SCADA systems is not just a technical upgrade but a strategic investment that can yield substantial returns in operational efficiency, cost savings, and competitive advantage.