SCADA: A Comprehensive Guide to Supervisory Control and Data Acquisition Systems

SCADA: A Comprehensive Guide to Supervisory Control and Data Acquisition Systems

Supervisory Control and Data Acquisition (SCADA) systems are integral to modern industrial operations, providing essential monitoring and control capabilities across various sectors. From manufacturing and energy to water management and transportation, SCADA systems enhance efficiency, safety, and reliability. Understanding SCADA's components, functionalities, and applications can help businesses optimize their operations and maintain a competitive edge.

What is SCADA?

SCADA stands for Supervisory Control and Data Acquisition, a system architecture that enables organizations to control industrial processes locally or remotely. It collects real-time data from various sensors and devices, processes the information, and allows operators to make informed decisions. SCADA systems are crucial for maintaining operational efficiency and ensuring safety in complex industrial environments.

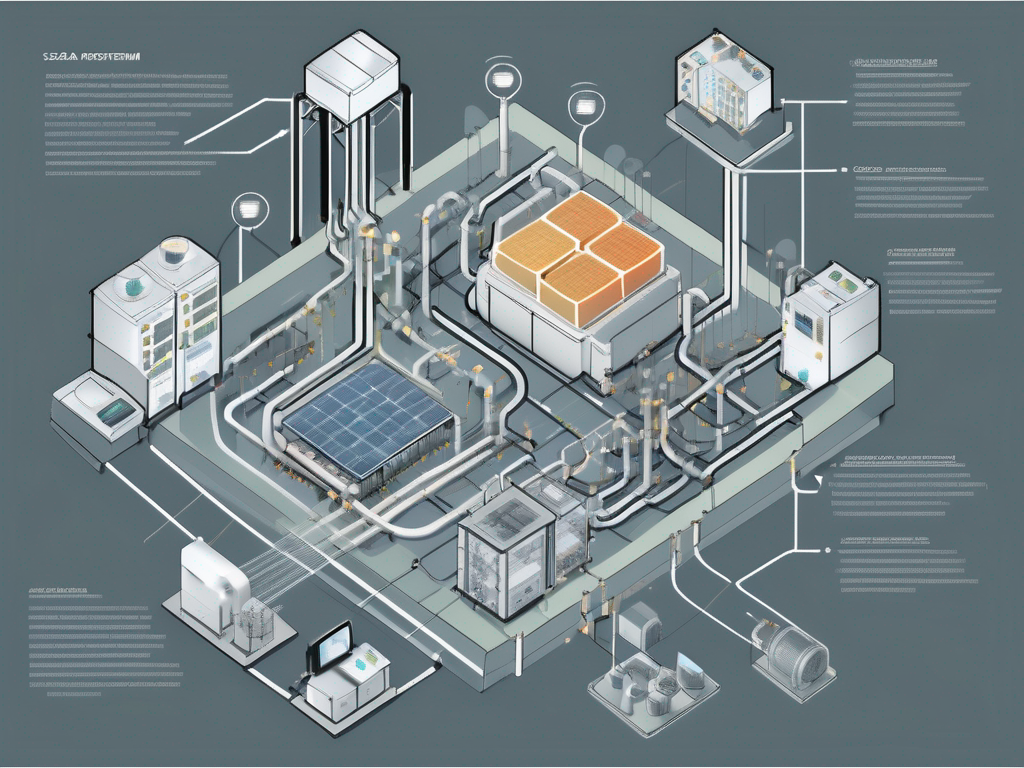

At its core, a SCADA system consists of hardware and software components. The hardware includes sensors, controllers, and communication devices, while the software provides a user interface for monitoring and controlling processes. SCADA systems are designed to handle large volumes of data, offering real-time insights into system performance and potential issues.

SCADA systems are highly customizable, allowing organizations to tailor their setup to meet specific operational needs. This flexibility makes SCADA applicable across various industries, from oil and gas to manufacturing and utilities. By integrating SCADA, businesses can achieve greater control over their processes, reduce downtime, and improve overall productivity.

Key Components of SCADA Systems

Human-Machine Interface (HMI)

The Human-Machine Interface (HMI) is the user interface that connects operators to the SCADA system. It displays real-time data, system status, and alerts, allowing operators to monitor and control processes effectively. HMIs are designed to be intuitive, providing easy access to critical information and enabling quick decision-making.

Modern HMIs offer advanced features such as touch-screen capabilities, customizable dashboards, and remote access. These features enhance user experience and ensure that operators can respond promptly to any issues that arise. By providing a clear and comprehensive view of system operations, HMIs play a crucial role in maintaining efficiency and safety.

Programmable Logic Controllers (PLCs)

Programmable Logic Controllers (PLCs) are essential components of SCADA systems, responsible for executing control actions based on predefined logic. PLCs receive input from sensors and devices, process the data, and send commands to actuators and other equipment. They are highly reliable and can operate in harsh industrial environments.

PLCs are programmable, allowing organizations to customize their control logic to suit specific operational requirements. This flexibility makes PLCs ideal for a wide range of applications, from simple process control to complex automation tasks. By integrating PLCs into SCADA systems, businesses can achieve precise control over their operations, enhancing efficiency and reducing the risk of errors.

Remote Terminal Units (RTUs)

Remote Terminal Units (RTUs) are field devices that collect data from sensors and transmit it to the central SCADA system. RTUs are designed to operate in remote or harsh environments, making them ideal for applications such as oil and gas pipelines, water treatment facilities, and power distribution networks.

RTUs are equipped with communication capabilities, allowing them to send and receive data over long distances. They can also perform local control functions, reducing the need for constant communication with the central system. By providing reliable data acquisition and control, RTUs are critical to the effective operation of SCADA systems.

Benefits of Implementing SCADA Systems

Enhanced Operational Efficiency

SCADA systems provide real-time monitoring and control, enabling organizations to optimize their operations and reduce waste. By collecting and analyzing data from various sources, SCADA systems help identify inefficiencies and areas for improvement. This data-driven approach allows businesses to make informed decisions and implement changes that enhance productivity and reduce costs.

Automation is another key benefit of SCADA systems. By automating routine tasks and processes, organizations can free up valuable resources and focus on more strategic activities. Automation also reduces the risk of human error, ensuring consistent and reliable operations.

Improved Safety and Compliance

Safety is a top priority in industrial operations, and SCADA systems play a crucial role in maintaining safe working environments. By providing real-time alerts and notifications, SCADA systems help operators respond quickly to potential hazards and prevent accidents. This proactive approach to safety reduces the risk of injuries and equipment damage.

SCADA systems also support regulatory compliance by providing accurate and timely data for reporting purposes. By maintaining detailed records of operations, organizations can demonstrate compliance with industry standards and regulations. This not only helps avoid penalties but also enhances the company's reputation and credibility.

Reduced Downtime and Maintenance Costs

Unplanned downtime can be costly for businesses, leading to lost productivity and revenue. SCADA systems help minimize downtime by providing early warning of potential issues and enabling predictive maintenance. By identifying and addressing problems before they escalate, organizations can avoid costly repairs and extend the lifespan of their equipment.

Predictive maintenance is a key feature of SCADA systems, allowing organizations to schedule maintenance activities based on actual equipment condition rather than fixed intervals. This approach reduces unnecessary maintenance and associated costs, ensuring that resources are used efficiently.

Applications of SCADA Systems Across Industries

Energy and Utilities

In the energy sector, SCADA systems are used to monitor and control power generation, transmission, and distribution. They provide real-time data on grid performance, enabling operators to manage load distribution and prevent outages. SCADA systems also support renewable energy integration, optimizing the use of solar and wind resources.

Utilities rely on SCADA systems to manage water and wastewater treatment processes. By monitoring flow rates, pressure, and chemical levels, SCADA systems ensure that water quality meets regulatory standards. They also help optimize resource use, reducing energy consumption and operational costs.

Manufacturing and Production

Manufacturers use SCADA systems to monitor production lines, track inventory levels, and manage quality control. By providing real-time data on equipment performance, SCADA systems help identify bottlenecks and optimize production processes. This leads to increased efficiency, reduced waste, and improved product quality.

SCADA systems also support just-in-time manufacturing by providing accurate data on inventory levels and demand. This enables manufacturers to adjust production schedules and minimize inventory holding costs. By enhancing visibility and control, SCADA systems help manufacturers remain competitive in a fast-paced market.

Transportation and Infrastructure

In the transportation sector, SCADA systems are used to monitor and control traffic signals, railway systems, and airport operations. They provide real-time data on traffic flow, enabling operators to manage congestion and improve safety. SCADA systems also support predictive maintenance, reducing downtime and ensuring reliable service.

Infrastructure projects, such as smart cities, rely on SCADA systems to integrate various systems and optimize resource use. By providing real-time data on energy consumption, water use, and waste management, SCADA systems support sustainable development and enhance quality of life for residents.

Challenges and Considerations in SCADA Implementation

Cybersecurity Risks

As SCADA systems become more interconnected, they are increasingly vulnerable to cyberattacks. Protecting SCADA systems from unauthorized access and data breaches is critical to maintaining operational integrity and safety. Organizations must implement robust cybersecurity measures, including firewalls, encryption, and access controls, to safeguard their SCADA systems.

Regular security assessments and updates are essential to address emerging threats and vulnerabilities. By adopting a proactive approach to cybersecurity, organizations can minimize the risk of attacks and ensure the continued reliability of their SCADA systems.

Integration with Existing Systems

Integrating SCADA systems with existing infrastructure can be challenging, particularly in legacy environments. Organizations must ensure compatibility between SCADA components and existing hardware and software. This may require custom development or the use of middleware solutions to facilitate communication and data exchange.

Successful integration also depends on effective project management and stakeholder collaboration. By involving key stakeholders in the planning and implementation process, organizations can address potential issues and ensure a smooth transition to SCADA systems.

Cost and Resource Considerations

Implementing a SCADA system can be a significant investment, requiring careful consideration of costs and resources. Organizations must evaluate the total cost of ownership, including hardware, software, installation, and ongoing maintenance. It is essential to develop a clear business case that demonstrates the potential return on investment and aligns with organizational goals.

Resource availability is another critical factor in SCADA implementation. Organizations must ensure they have the necessary skills and expertise to design, deploy, and maintain the system. This may involve training existing staff or hiring external consultants to provide specialized support.

Future Trends in SCADA Systems

Integration with IoT and Big Data

The integration of SCADA systems with the Internet of Things (IoT) and big data technologies is transforming industrial operations. By connecting SCADA systems to IoT devices, organizations can collect and analyze vast amounts of data, gaining deeper insights into their processes. This data-driven approach supports predictive analytics, enabling organizations to optimize operations and improve decision-making.

Big data technologies also enhance SCADA systems' ability to process and store large volumes of data. By leveraging cloud-based solutions, organizations can access scalable storage and computing resources, reducing the need for on-premises infrastructure. This flexibility supports the growing demand for real-time data analysis and reporting.

Advancements in Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are driving innovation in SCADA systems, enabling more sophisticated data analysis and decision-making. By incorporating AI and ML algorithms, SCADA systems can identify patterns and anomalies in data, supporting predictive maintenance and process optimization.

AI-powered SCADA systems also enhance automation capabilities, allowing organizations to implement more complex control strategies. This leads to increased efficiency, reduced downtime, and improved safety. As AI and ML technologies continue to evolve, their integration with SCADA systems will unlock new opportunities for innovation and growth.

Focus on Sustainability and Energy Efficiency

As organizations prioritize sustainability and energy efficiency, SCADA systems are playing a crucial role in supporting these initiatives. By providing real-time data on energy consumption and resource use, SCADA systems help organizations identify opportunities for improvement and implement energy-saving measures.

SCADA systems also support the integration of renewable energy sources, optimizing their use and reducing reliance on fossil fuels. By enhancing visibility and control over energy use, SCADA systems enable organizations to achieve their sustainability goals and reduce their environmental impact.

In conclusion, SCADA systems are essential tools for modern industrial operations, offering significant benefits in terms of efficiency, safety, and reliability. By understanding the key components, applications, and challenges of SCADA systems, organizations can make informed decisions and leverage these technologies to drive innovation and growth.