Understanding Booster System Pumps: A Comprehensive Guide

Introduction to Booster System Pumps

Booster system pumps are essential devices used in various applications to enhance and maintain adequate water pressure and flow rates in plumbing systems. They play a vital role in ensuring that water reaches its intended destinations, especially in high-rise buildings, irrigation systems, and industrial processes. Understanding the operation and significance of booster system pumps can help you make informed decisions regarding their selection, installation, and maintenance.

Definition and Function of Booster System Pumps

A booster pump is a mechanical device designed to increase the pressure within a liquid distribution system. It effectively boosts the existing water pressure to meet the demands of users, ensuring a steady supply of water irrespective of the initial source pressure. The primary function of these pumps is to maintain consistent water flow and pressure in applications where elevated levels are essential.

Common scenarios where booster pumps are utilized include residential buildings, multi-story commercial structures, and fire protection systems. In each application, they encourage efficient water distribution, alleviating issues related to low pressure that compromise performance and reliability. Additionally, booster pumps can be equipped with variable frequency drives (VFDs) that allow for precise control over the pump's operation, adapting to fluctuating demand and optimizing energy consumption.

Importance of Booster System Pumps

The role of booster system pumps extends far beyond merely increasing water pressure. They are critical for optimal functionality in numerous systems, ensuring that every outlet, sprinkler, or hose draws the required amount of water without interruption. This importance translates into enhanced comfort, safety, and operational effectiveness in residential, commercial, and industrial environments.

Moreover, investing in proper booster pump systems can lead to significant water savings and reduced operational costs. When designed and implemented correctly, these pumps can improve energy efficiency, lower utility bills, and extend the lifespan of plumbing systems by minimizing the strain caused by fluctuating pressure levels. Additionally, regular maintenance of booster pumps is crucial; it not only ensures their longevity but also prevents unexpected failures that could lead to costly repairs or water shortages. By incorporating routine inspections and timely servicing, property owners can safeguard their water supply systems and enhance overall performance.

Furthermore, the integration of smart technology in booster pump systems is becoming increasingly prevalent. These advanced systems can monitor pressure levels in real-time, providing alerts for any irregularities and allowing for proactive adjustments. Such innovations not only streamline operations but also contribute to sustainability efforts by reducing waste and optimizing resource use. As water scarcity becomes a more pressing global issue, the role of efficient booster pumps in conserving water and ensuring reliable access cannot be overstated.

Types of Booster System Pumps

Booster system pumps come in various designs and configurations, each suited for specific applications and requirements. Understanding the types of booster pumps available can help you choose the right one for your needs. Below are the two primary categories of booster system pumps:

Single Stage Booster Pumps

Single stage booster pumps are designed to create pressure in a single stage of operation. They are typically more compact and less complex than multi-stage pumps, making them a popular choice for residential use and low-rise buildings. These pumps are ideal for applications where moderate pressure boosts are required without extensive plumbing work.

Due to their simpler design, single stage booster pumps are often easier to install and maintain, making them accessible for homeowners and small business owners looking for cost-effective solutions. These pumps usually have a lower flow rate, making them suitable for smaller systems or low consumption scenarios. They can be particularly effective in boosting water pressure for domestic applications such as shower systems, garden irrigation, and small-scale commercial setups. Additionally, many single stage pumps are designed to operate quietly, which is an essential consideration for residential environments where noise levels need to be kept to a minimum.

Multi-Stage Booster Pumps

Multi-stage booster pumps consist of multiple impellers, allowing them to generate higher pressures compared to single-stage models. They are particularly beneficial in high-rise buildings, expansive irrigation systems, and industrial applications where significant pressure increases are necessary to accommodate long horizontal runs and vertical lifts.

The design of multi-stage pumps enables them to achieve higher efficiencies at varying flow rates, which improves energy usage over time. While they tend to be more complex and require more maintenance than their single-stage counterparts, they are essential for demanding applications where consistent high pressure is non-negotiable. Furthermore, multi-stage pumps can be configured to operate in parallel or series, providing flexibility in system design and allowing for scalability as demand increases. This adaptability makes them a preferred choice for large-scale projects, such as municipal water supply systems and large commercial buildings, where reliability and performance are critical. In addition, advancements in technology have led to the development of variable speed multi-stage pumps, which can adjust their operating speed based on real-time demand, further enhancing energy efficiency and system longevity.

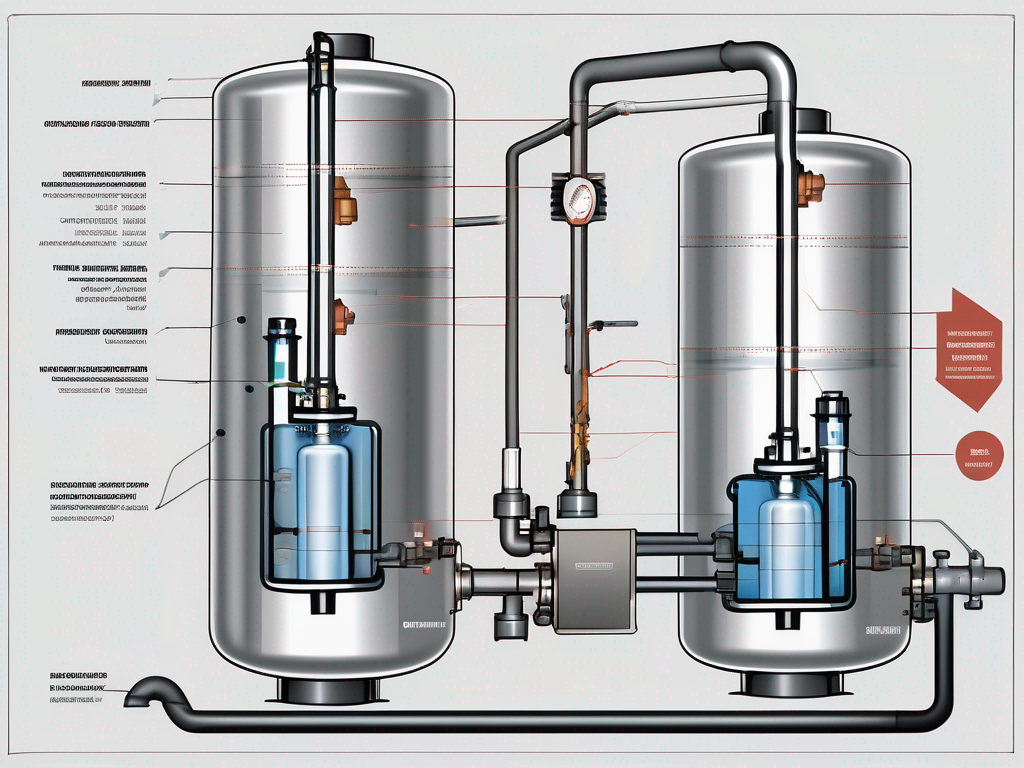

Components of Booster System Pumps

Understanding the key components of booster system pumps can help in appreciating their functionality and maintenance requirements. Here are the critical components that make these systems work effectively:

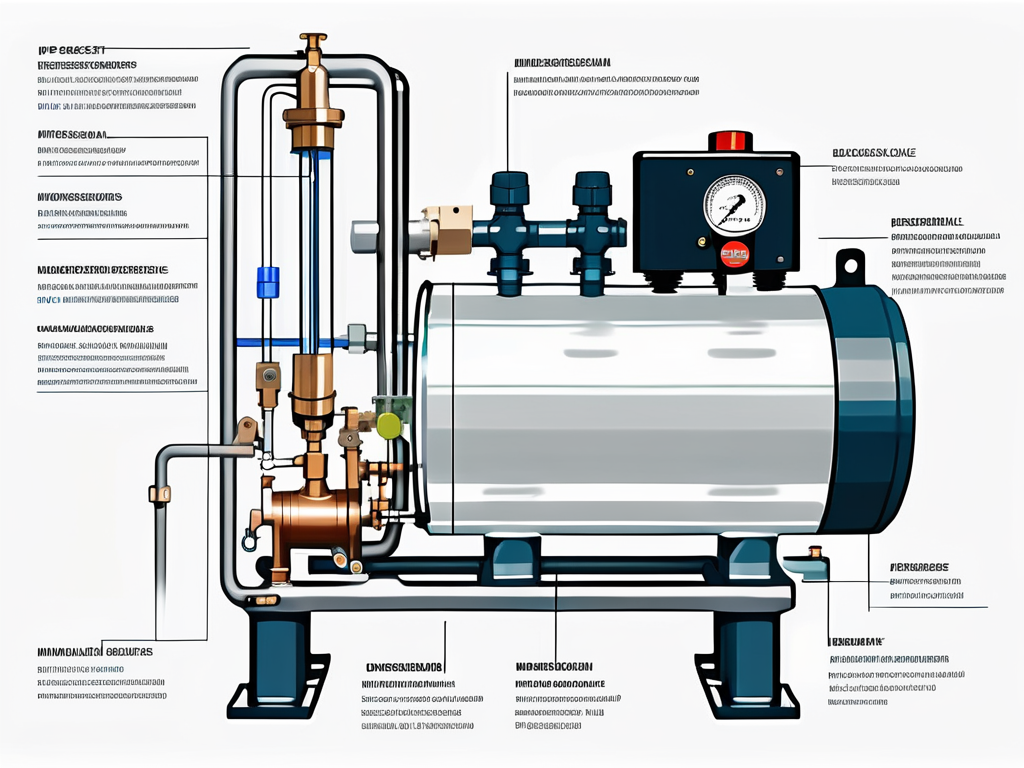

Pump Motor

The pump motor is the heart of a booster system pump. It provides the necessary power to drive the impeller and create the required pressure boost. Motors can vary in terms of size, type (electric, diesel, etc.), and efficiency. Selecting the right motor is crucial for the pump’s overall performance and energy efficiency.

Regular inspection and maintenance of the motor are vital to ensure long-term reliability and performance. Signs of wear or malfunction should be addressed immediately to prevent operational downtime and costly repairs. Additionally, understanding the motor's power requirements and how they align with the system's demands can lead to better energy management and cost savings over time. For instance, opting for high-efficiency motors can significantly reduce energy consumption, benefiting both the environment and the operating budget.

Pressure Tanks

Pressure tanks play a pivotal role in booster systems, storing pressurized water and maintaining water pressure within the system. By absorbing fluctuations in water flow, pressure tanks help stabilize the pressure in plumbing systems, enhancing comfort and efficiency.

These tanks can be either bladder or diaphragm types, each serving the same purpose but functioning in slightly different ways. Adequate sizing and maintenance of pressure tanks are essential for optimal system performance and to avoid issues such as water hammer or excessive cycling of the pump. Furthermore, regular inspections can help identify potential leaks or corrosion, which can compromise the integrity of the tank. Implementing a routine maintenance schedule not only extends the life of the pressure tanks but also ensures that the entire booster system operates smoothly, providing consistent water pressure to meet demand.

Control Panel

The control panel is the brain of the booster pump system, overseeing operations and ensuring optimal performance. It regulates the operation of the pump based on incoming water pressure and demand, providing automatic control features that can enhance overall efficiency.

Modern control panels often come equipped with advanced features like remote monitoring, fault diagnostics, and energy-saving settings. Regular checks and updates on software and hardware components are necessary to keep the system functioning efficiently. In addition, the integration of smart technology allows for real-time data analysis, enabling operators to make informed decisions regarding system adjustments and maintenance. This proactive approach not only minimizes downtime but also enhances the overall performance of the booster system, ensuring that it meets the varying demands of users effectively.

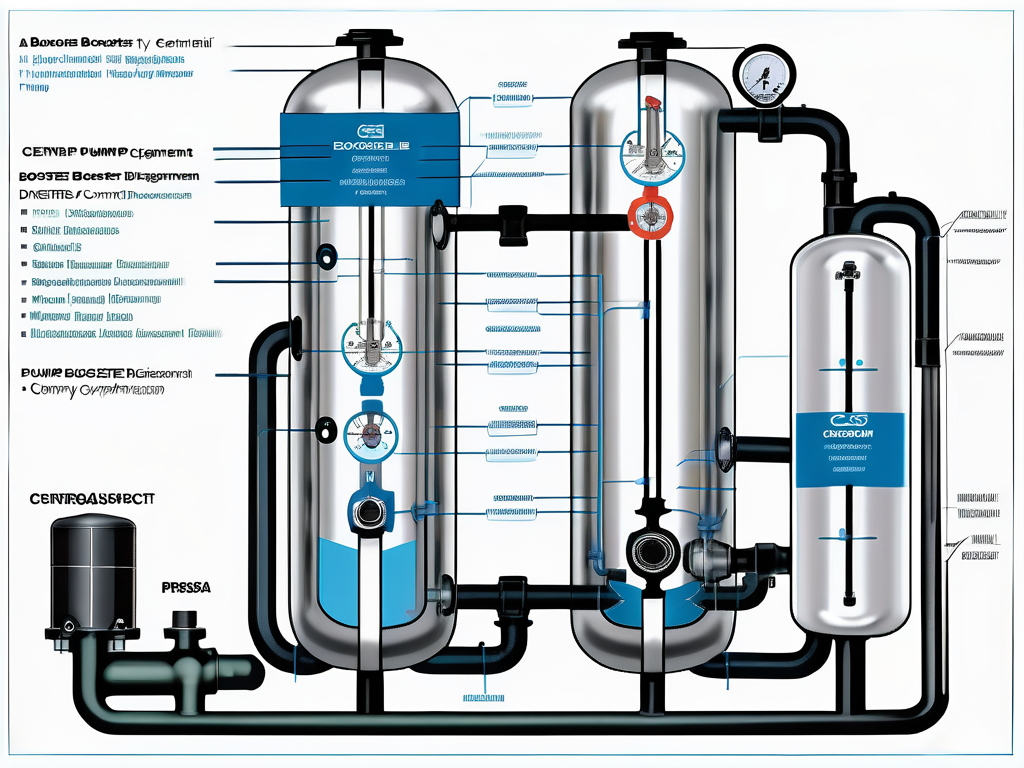

Working Principle of Booster System Pumps

The operation of booster system pumps hinges on a few fundamental principles that work in tandem to create the necessary pressure. Understanding these principles provides insights into how these systems efficiently serve various applications.

Pumping Process

The pumping process begins when the booster pump is activated, drawing water from the supply source. As water enters the pump, it is propelled by the pump impeller, which spins rapidly and imparts kinetic energy to the water.

This kinetic energy is then converted into hydraulic energy, increasing the water’s pressure as it exits the pump and enters the distribution system. This entire process enables the booster pump to provide the necessary force to push water through plumbing systems, even against the force of gravity in high-rise applications. The design of the impeller, including its shape and material, plays a significant role in determining the pump's efficiency and effectiveness. High-quality materials can withstand corrosion and wear, ensuring longevity and reliability in various environments, from residential buildings to industrial facilities.

Pressure Regulation

Pressure regulation is a critical aspect of booster system pump operations. A properly functioning pressure regulation system ensures that the water flowing through the pipes remains within the desired range of pressure. This is vital to prevent damage to plumbing fixtures and maintain a steady supply of water for intended uses.

Pressure switches and sensors work together to monitor pressure levels within the system, automatically adjusting pump operations based on real-time conditions. This responsiveness enhances efficiency, reduces energy consumption, and prolongs the life of the pump and connected components. Additionally, advanced systems may incorporate variable frequency drives (VFDs) that allow for even finer control over pump speed and output, adapting to fluctuating demand. This technology not only optimizes performance but also contributes to significant energy savings, making booster pumps a more sustainable choice in water management.

Furthermore, the integration of smart technology in pressure regulation systems is becoming increasingly prevalent. These smart systems can provide remote monitoring and diagnostics, allowing operators to track performance metrics and identify potential issues before they escalate. This proactive approach not only enhances the reliability of the booster pump system but also aids in maintenance scheduling, ensuring that the system operates at peak efficiency throughout its lifespan.

Maintenance and Troubleshooting of Booster System Pumps

Regular maintenance and prompt troubleshooting are key to ensuring the longevity and efficiency of booster system pumps. Implementing a systematic approach to maintenance can reduce operational costs and enhance performance.

Regular Maintenance Practices

Routine maintenance should include checking the pressure levels, inspecting the pump motor and components for signs of wear, and cleaning filters and strainers to prevent clogs. Scheduling these tasks helps avoid unexpected failures and downtime.

It's also essential to keep an eye on any noise or vibration from the pump, which could indicate issues such as misalignment or damage. Monthly or quarterly inspections can be invaluable for identifying potential problems before they escalate. Regular maintenance can significantly extend the lifespan of your pump and ensure consistent performance. Additionally, maintaining a clean environment around the pump can prevent dust and debris from entering the system, which can lead to further complications. It’s advisable to document all maintenance activities, as this can provide valuable insights into the pump's performance over time and help in forecasting future maintenance needs.

Common Problems and Solutions

Booster pumps can encounter various issues during their operation. Common problems include loss of pressure, unexpected noise, and leaks. Identifying the root cause is crucial for swift resolution.

- Loss of Pressure: Often caused by air leaks in the system, insufficient power supply, or a malfunctioning pressure switch.

- Unusual Noise: This may indicate an issue with the motor or impeller, requiring immediate inspection to prevent further damage.

- Leaks: Check the connections and seals for integrity, as leaks can compromise system pressure and efficiency.

Implementing troubleshooting guides and maintenance logs can help detect patterns and problems, enhancing your troubleshooting capabilities. Furthermore, understanding the operational environment of the booster pump is essential. Factors such as temperature fluctuations, humidity, and the type of fluid being pumped can all affect performance. For instance, if the pump is used in a corrosive environment, regular checks for corrosion and material degradation are necessary. Utilizing advanced monitoring technologies, such as vibration analysis and thermal imaging, can provide deeper insights into the pump's operational health, allowing for predictive maintenance strategies that can preemptively address issues before they lead to costly repairs or replacements.

Safety Measures for Using Booster System Pumps

Ensuring the safety of booster pump operations is crucial not only for personnel but also for the integrity of plumbing systems. Implementing effective safety measures protects both people and property.

Installation Safety

Installation procedures must adhere to local codes and manufacturer guidelines. This involves properly securing all connections and ensuring that the pump is correctly mounted and adequately supported. Properly sized piping should also be installed to avoid pressure losses.

Using trained and certified professionals for installation is paramount. Involving experienced personnel helps in mitigating risks and ensuring compliance with safety standards. Additionally, conducting a thorough site assessment before installation can identify potential hazards, such as proximity to electrical sources or areas prone to flooding, which can significantly impact the safety and efficiency of the booster pump system.

Operational Safety

During operation, it’s critical to monitor system parameters continuously to ensure safe functionality. Implementing alarms and controls can help promptly address any abnormal readings or pressures.

Safety training for operators should include emergency procedures, proper use of equipment, and awareness of potential hazards associated with high-pressure systems. Regular safety drills and training can enhance readiness and response capabilities. Furthermore, establishing a routine maintenance schedule is essential to inspect components such as valves, seals, and electrical connections. This proactive approach not only helps in identifying wear and tear before it leads to failures but also reinforces a culture of safety and vigilance among the operational team.

Future Trends in Booster System Pumps

The future of booster system pumps is bright, driven by technological advancements and evolving market demands. Understanding upcoming trends helps in staying ahead and planning for future needs.

Technological Advancements

Emerging technologies such as smart pump systems, IoT integration, and artificial intelligence are set to transform booster pump operations. These innovations allow for real-time monitoring, predictive maintenance, and improved efficiency through enhanced data analysis.

As manufacturers continue to prioritize energy efficiency, expect to see advancements like variable speed drives and energy-efficient motors as standard features in booster pump designs. These technologies resonate with the growing trend toward sustainability and operational improvement.

Moreover, the integration of machine learning algorithms into pump systems is enabling predictive analytics, which can forecast potential failures before they occur. This proactive approach not only reduces downtime but also extends the lifespan of the equipment. The ability to analyze vast amounts of operational data in real-time allows for fine-tuning of pump performance, ensuring that systems operate at optimal levels under varying conditions.

Environmental Impact and Sustainability

The increasing emphasis on environmental impact is reshaping the landscape of booster system pumps. Manufacturers are focusing on creating systems that minimize energy use, reducing carbon footprints while still meeting pressures and flow requirements.

Water conservation efforts are also influencing the design and implementation of booster systems, with initiatives that promote efficient use and recycling of water. This commitment to sustainability will play a crucial role in future developments in booster pump technology.

In addition, the push for regulatory compliance regarding emissions and energy consumption is driving innovation in the industry. Companies are exploring alternative materials and eco-friendly manufacturing processes that not only lower environmental impact but also enhance the durability and reliability of booster pumps. The rise of circular economy principles is encouraging manufacturers to consider the entire lifecycle of their products, from design and production to end-of-life recycling, ensuring that sustainability is embedded in every step of the process.

Conclusion: Maximizing the Efficiency of Your Booster System Pump

Understanding the fundamental aspects of booster system pumps equips users with the knowledge necessary to optimize their performance and lifespan. By recognizing the different types, components, and operational principles, users can make informed decisions that enhance their pumping systems.

Investing in regular maintenance, adhering to safety standards, and staying current with emerging trends guarantees not only the efficient functioning of booster pumps but also contributes to long-term sustainability. As the needs for efficient and reliable water distribution systems continue to grow, booster system pumps will remain a crucial element in meeting those demands.