Understanding Chlorine Injection: Benefits and Applications

Chlorine injection is a critical process widely used to treat water, ensuring its safety and quality for a variety of applications. This article aims to explore the fundamentals of chlorine injection, its benefits, applications, safety measures, and future trends. By delving into these aspects, we will provide a comprehensive understanding of chlorine injection and its importance in our modern environment.

What is Chlorine Injection?

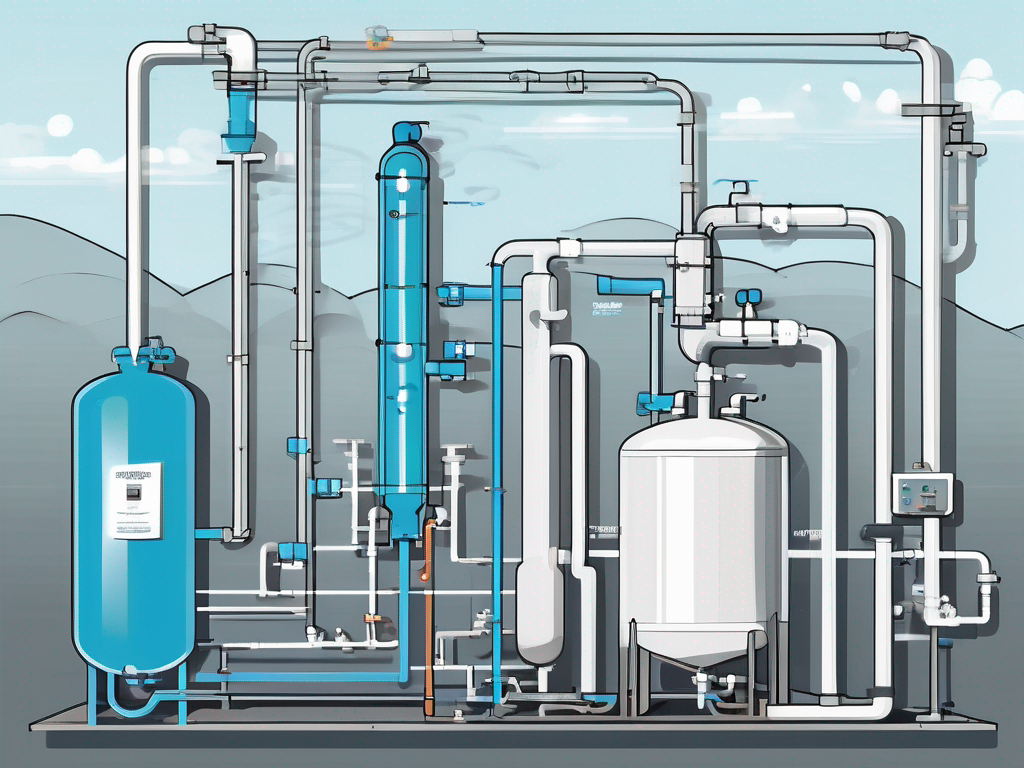

Chlorine injection refers to the method of adding chlorine, usually in gas or liquid form, to water systems. This process aims to disinfect and purify the water, making it safe for human consumption and various industrial uses. Often implemented in municipal water treatment plants, swimming pools, and industrial applications, chlorine injection serves as a simple yet effective measure to eliminate harmful microorganisms.

The Basics of Chlorine Injection

The concept of chlorine injection is straightforward: chlorine’s strong oxidizing properties enable it to kill bacteria, viruses, and other pathogens present in water. This is achieved by introducing chlorine into the water supply and allowing it to mix uniformly. The concentration and contact time with the water determine the effectiveness of this disinfection method.

During the injection process, several factors influence the dose of chlorine needed, including the water's pH, temperature, and turbidity levels. Water treatment professionals typically calculate the required dosage based on these parameters to ensure maximum efficiency. Additionally, the flow rate of the water system can significantly impact how well chlorine disperses, necessitating careful calibration of injection systems to achieve optimal results.

The Science Behind Chlorine Injection

The science of chlorine injection hinges on its chemical properties. Chlorine interacts with water to form hypochlorous acid (HOCl) and hypochlorite ion (OCl-), both of which are effective disinfectants. Hypochlorous acid is particularly potent and is the primary agent that inactivates pathogens.

Moreover, chlorine’s ability to form chlorinated by-products can pose some challenges, leading to potential health concerns. Understanding these reactions is crucial for operators to minimize risks and adhere to health regulations. Thus, appropriate monitoring and control systems are essential components of effective chlorine injection systems. Regular testing of water samples ensures that chlorine levels remain within safe limits while also checking for the presence of by-products like trihalomethanes (THMs), which can form when chlorine reacts with organic matter in the water.

Furthermore, the implementation of chlorine injection is not a one-size-fits-all solution. Different water sources, such as surface water or groundwater, may require tailored approaches to chlorine dosing and application. For instance, surface water often contains higher levels of organic material, necessitating a more careful management of chlorine levels to prevent excessive by-product formation. As water treatment technologies continue to evolve, the integration of advanced monitoring systems and alternative disinfection methods, such as UV treatment or ozonation, is becoming increasingly common, offering complementary solutions to enhance water safety.

The Benefits of Chlorine Injection

The use of chlorine injection brings numerous benefits, significantly impacting public health, environmental safety, and operational efficiency.

Improving Water Quality

One of the most significant benefits of chlorine injection is its effectiveness in improving water quality. By eliminating harmful microorganisms, chlorine minimizes the risk of waterborne diseases that can pose serious health consequences. This process is a fundamental aspect of drinking water treatment, protecting communities from potential outbreaks.

Furthermore, chlorine improves the overall aesthetic qualities of water. It helps control the growth of algae and other unwanted organisms, leading to clearer, odor-free drinking water. The presence of chlorine not only enhances visual clarity but also ensures that the water remains palatable, which is crucial for encouraging communities to stay hydrated and consume adequate amounts of water daily.

Moreover, chlorine injection can be tailored to specific water sources and conditions, allowing for customized treatment protocols that maximize effectiveness. This adaptability is particularly beneficial in areas with varying levels of contamination or in emergency situations where rapid response is required to safeguard public health.

Health Advantages of Chlorine Injection

The health advantages of chlorine injection cannot be overstated. By disinfecting water supplies, it reduces the incidence of diseases such as cholera, typhoid, and dysentery. These diseases can spread rapidly, particularly in regions lacking proper sanitation, making chlorine injection a vital public health strategy.

Additionally, regular disinfection through chlorine ensures that water remains safe from re-contamination during storage and distribution, extending the health benefits to entire communities. This is especially important in developing regions where infrastructure may be lacking, as it helps to create a reliable barrier against potential pathogens that could compromise health.

Chlorine also plays a role in public health education, as communities become more aware of the importance of safe drinking water. This awareness can lead to increased demand for water quality monitoring and improvement initiatives, fostering a culture of health and safety that benefits all residents.

Environmental Impact of Chlorine Injection

While chlorine injection is crucial for maintaining water safety, it is essential to consider its environmental impact. When used responsibly, chlorine injection minimizes the amount of pollutants entering natural water systems, thus preserving aquatic ecosystems.

However, the formation of chlorinated by-products, such as trihalomethanes (THMs)—which occur when chlorine reacts with organic matter—can have detrimental environmental effects. Therefore, updated technologies and practices aimed at reducing these by-products are continuously being developed and implemented to balance public health concerns with environmental sustainability.

Innovative approaches, such as the use of alternative disinfectants and advanced oxidation processes, are being explored to mitigate the environmental footprint of chlorine injection. These methods not only aim to reduce harmful by-products but also enhance the overall efficiency of water treatment processes, ensuring that both human health and the environment are prioritized in water management strategies.

Applications of Chlorine Injection

Chlorine injection finds its application across various sectors, each leveraging its disinfectant properties to ensure safety and compliance.

Chlorine Injection in Water Treatment

The primary arena for chlorine injection is water treatment facilities. Municipal water systems throughout the world rely on this process to guarantee the removal of pathogens, ensuring that water is safe for public consumption.

Operators continually monitor chlorine levels to maintain optimal disinfection while complying with regulatory standards. This ongoing effort guarantees that citizens receive clean drinking water, contributing significantly to overall community health. Moreover, the process of chlorination not only eliminates harmful bacteria and viruses but also helps in controlling algae growth and reducing unpleasant tastes and odors associated with waterborne contaminants, thus enhancing the overall quality of the water supplied.

Industrial Uses of Chlorine Injection

Beyond water treatment plants, several industries utilize chlorine injection to maintain hygiene standards. The food and beverage industry, for instance, employs chlorine to sanitize equipment and surfaces, thus preventing contamination.

Additionally, industrial facilities often require sanitized water for cooling systems, process water, and wastewater treatment. Chlorine injection provides a reliable method to meet these stringent hygiene and safety requirements. Furthermore, in the pharmaceutical sector, chlorine is instrumental in ensuring that water used in drug manufacturing is free from microbial contamination, which is crucial for maintaining product integrity and safety. The versatility of chlorine injection makes it an essential component in various industrial processes, where maintaining a sterile environment is paramount.

Chlorine Injection in Swimming Pools

Chlorine injection is perhaps most familiar in the context of swimming pools. Pool owners and managers regularly utilize chlorine to maintain water safety and clarity for patrons. The practice helps eliminate harmful organisms, providing a safe recreational environment.

The concentration levels and types of chlorine used in swimming pools can vary, with options like chlorine tablets, granules, or liquid solutions available. Each choice offers distinct advantages, and professional pool service providers can recommend the best application based on specific needs. In addition to regular chlorine dosing, pool operators often conduct shock treatments, which involve adding a higher concentration of chlorine to quickly eliminate contaminants and restore water clarity. This proactive approach not only enhances the swimming experience but also extends the life of pool equipment by preventing the buildup of harmful substances that can cause corrosion and damage over time.

Safety Measures and Precautions

Given the potency of chlorine, implementing safety measures is crucial to protect both operators and the environment from potential hazards associated with chlorine injection.

Handling and Storage of Chlorine

Proper handling and storage of chlorine are integral to maintaining safety. Chlorine should be stored in well-ventilated areas away from combustible materials and other chemicals. Regulations dictate specific container types and procedures to prevent accidental releases or reactions.

Individuals handling chlorine must undergo training to understand the risks and adhere to proper safety protocols. Wearing appropriate personal protective equipment (PPE) is also essential to mitigate exposure risks during handling procedures. This includes gloves, goggles, and respiratory protection, which can significantly reduce the likelihood of inhalation or skin contact with chlorine gas, a potent irritant that can cause serious health issues.

Furthermore, it is important to establish a clear protocol for emergency situations, including spill response and evacuation plans. Regular drills can help ensure that all personnel are familiar with these procedures, enhancing overall safety and preparedness in the event of an incident.

Safety Equipment for Chlorine Injection

Implementing adequate safety equipment is vital in facilities that utilize chlorine injection. Systems such as leak detection alarms, emergency shut-off valves, and personal protective gear must be readily available.

Regular maintenance and inspections of the chlorine injection equipment and safety systems are necessary to ensure optimal performance. Investing in robust safety measures protects workers and helps to prevent environmental contamination. Additionally, the installation of secondary containment systems can further minimize the risk of accidental releases, ensuring that any leaks are contained and do not pose a threat to surrounding areas.

Moreover, the integration of advanced monitoring technologies can enhance safety protocols. Real-time monitoring systems can track chlorine levels and detect any irregularities, allowing for immediate corrective actions. This proactive approach not only safeguards the health of employees but also contributes to compliance with environmental regulations, promoting a culture of safety and responsibility within the organization.

Future Trends in Chlorine Injection

The landscape of chlorine injection is continually evolving, driven by advancements in technology and an increasing focus on sustainability. This section explores upcoming trends that will shape the future of chlorine injection.

Technological Advancements in Chlorine Injection

Innovations in technology are enhancing the efficiency and effectiveness of chlorine injection systems. Advanced monitoring systems that utilize real-time data analytics help operators maintain optimal chlorine levels and detect potential issues proactively.

Moreover, automated injection systems are becoming more prevalent, reducing manual labor and the risk of human error. As technology evolves, these advancements will streamline chlorine injection processes and enhance overall water safety. In addition, the integration of artificial intelligence (AI) into these systems is paving the way for predictive maintenance, allowing for the anticipation of equipment failures before they occur. This not only increases the reliability of chlorine injection systems but also minimizes downtime, ensuring a continuous supply of safe water.

Furthermore, the development of smart sensors that can analyze water quality in real-time is revolutionizing the industry. These sensors can detect variations in water chemistry and automatically adjust chlorine levels accordingly, leading to more precise disinfection processes. Such innovations not only improve the safety of drinking water but also contribute to cost savings for municipalities and industries that rely on chlorine injection for their water treatment needs.

Sustainability and Chlorine Injection

With a growing emphasis on sustainability, the chlorine injection sector is also seeking greener alternatives. Developing methods to minimize the formation of chlorinated by-products during disinfection is a priority for researchers and water treatment professionals alike.

Furthermore, increasing awareness about water conservation and holistic environmental practices will drive the chlorine injection market toward more sustainable solutions, ensuring that water treatment can continue to protect public health without compromising ecological integrity. One promising area of research is the exploration of alternative disinfectants that can work alongside or even replace chlorine in certain applications. For instance, technologies such as ultraviolet (UV) light and ozone treatment are gaining traction as effective methods for disinfection that produce fewer harmful by-products.

Additionally, the implementation of closed-loop systems in chlorine injection processes is becoming more common. These systems recycle and reuse chlorine, significantly reducing chemical waste and minimizing the environmental footprint of water treatment facilities. As regulatory pressures increase and public demand for sustainable practices grows, the chlorine injection industry will likely continue to innovate and adapt, ensuring that it remains a vital component of modern water treatment while aligning with global sustainability goals.