Understanding Chlorine Injection Systems: A Comprehensive Guide

Chlorine injection systems play a vital role in the ongoing efforts to ensure safe and clean water for various applications, particularly in municipal water treatment and industrial processes. This comprehensive guide explores the basic concepts, potential benefits, maintenance practices, and future trends surrounding chlorine injection systems.

The Basics of Chlorine Injection Systems

Understanding the fundamentals of chlorine injection systems is essential for anyone involved in water treatment or looking to improve the quality of their water supply. A chlorine injection system is designed to add chlorine, a powerful disinfectant, to water in a controlled manner.

What is a Chlorine Injection System?

A chlorine injection system is a mechanism that delivers chlorine directly into a water supply. This process serves multiple purposes, such as disinfection, oxidation of contaminants, and maintaining a residual chlorine level in the water to ensure ongoing treatment effectiveness.

Typically, these systems operate by either injecting chlorine gas or injecting a liquid chlorine solution (sodium hypochlorite) into the water supply. The choice of method will depend on specific water quality requirements, local regulations, and overall system design. The effectiveness of chlorine as a disinfectant is well-documented, making it a popular choice for municipal water systems, swimming pools, and industrial applications alike. Furthermore, the ability to monitor and adjust chlorine levels in real-time enhances the safety and reliability of water treatment processes.

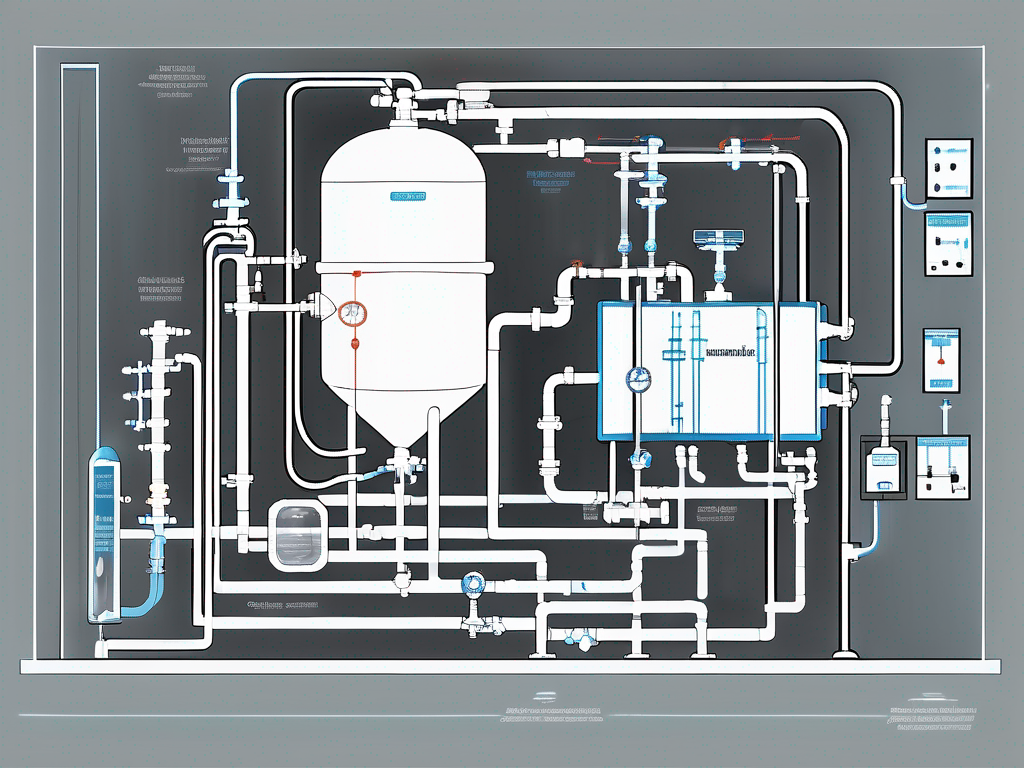

Key Components of a Chlorine Injection System

Every chlorine injection system comprises several key components, each serving a critical function:

- Chlorinator: The device responsible for dosing chlorine into the water. This can be a gas feed system or a liquid feed system.

- Injection Point: The location in the pipeline where the chlorine is introduced, often designed for optimal mixing.

- Flow Meters: Instruments that measure the flow rate of water, allowing for accurate chlorine dosing.

- Safety Equipment: Features such as alarms, sensors, and automatic shutoff systems for managing risks associated with chlorine use.

In addition to these components, many systems are equipped with advanced monitoring technologies that provide real-time data on chlorine levels, pH, and other critical parameters. This data is invaluable for operators, enabling them to make informed decisions about treatment adjustments and ensuring compliance with health and safety regulations. Moreover, regular maintenance of these systems is crucial; it not only prolongs the lifespan of the equipment but also ensures that the water remains safe and free from harmful pathogens.

Another important aspect of chlorine injection systems is their adaptability to various applications. For instance, in residential settings, smaller-scale systems can be installed to ensure safe drinking water, while larger systems are designed for municipal water treatment facilities, capable of handling significant volumes of water. The versatility of these systems makes them suitable for a wide range of environments, from agricultural irrigation to wastewater treatment, showcasing their critical role in public health and environmental protection.

The Role of Chlorine in Water Treatment

Chlorine's widespread use in water treatment processes is largely due to its effectiveness as a disinfectant and its ability to improve water quality. Understanding its role helps illuminate why we rely so heavily on it in various treatment systems.

Chlorine as a Disinfectant

As a powerful disinfectant, chlorine is exceptional at killing bacteria, viruses, and other pathogens that pose risks to public health. When introduced to water, chlorine disrupts microbial cell functions, neutralizing harmful organisms that could otherwise proliferate.

This disinfection capability makes chlorine essential for ensuring that drinking water is safe for consumption. It is commonly used in municipal treatment facilities, swimming pools, and even in residential water systems to maintain quality and safety. Moreover, chlorine's effectiveness is not limited to just bacteria; it also targets protozoa, such as Giardia and Cryptosporidium, which can be particularly resistant to other forms of disinfection. This makes chlorine a versatile choice in a variety of water treatment scenarios, from urban centers to rural communities.

Chlorine and Water Safety

Beyond immediate disinfection, chlorine also plays a role in maintaining water safety over time. By establishing a residual chlorine level within the distribution system, it helps to prevent the regrowth of pathogens as the water travels through pipes.

This residual effect is critical; without it, treated water could become re-contaminated before reaching its final destination, nullifying the initial disinfection efforts. Water utility operators carefully monitor chlorine levels to ensure public safety at all stages of distribution. In addition to its disinfecting properties, chlorine also reacts with organic matter in water, forming chlorinated byproducts. While these byproducts can raise concerns about potential health risks, regulatory agencies set strict limits to ensure that the benefits of chlorine disinfection far outweigh any associated risks. This careful balance is a testament to the ongoing research and advancements in water treatment technologies, which continue to evolve to enhance public health outcomes while addressing environmental concerns.

Types of Chlorine Injection Systems

There are various types of chlorine injection systems, each serving unique applications and requirements based on water quality, infrastructure, and regulatory conditions.

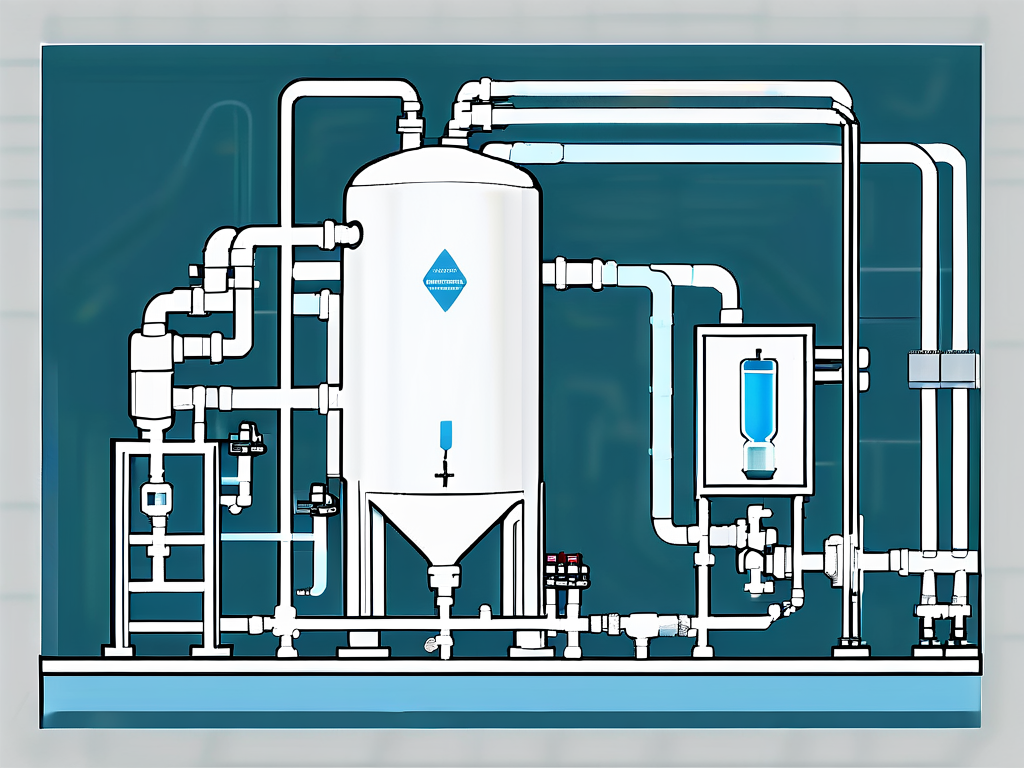

Liquid Chlorine Injection Systems

Liquid chlorine injection systems typically use sodium hypochlorite as their chlorine source. This method is common in smaller facilities or residential systems due to its ease of storage and handling.

With liquid systems, precise dosing equipment is necessary to ensure that the correct amount of chlorine is injected into the water supply, accounting for changes in flow rate and water quality. The use of advanced metering pumps can enhance the accuracy of chlorine dosing, allowing operators to maintain optimal disinfection levels even during fluctuations in water demand. Additionally, liquid chlorine systems can be equipped with automated monitoring systems that provide real-time feedback on chlorine levels, helping to ensure compliance with health and safety standards.

Gas Chlorine Injection Systems

Gas chlorine systems utilize compressed chlorine gas, which is injected into water through a specialized chlorinator. These systems are often used in larger municipal treatment facilities due to their ability to deliver chlorine efficiently and in higher volumes.

While effective, managing gas chlorine requires more rigorous safety protocols due to its hazardous nature. Proper training and monitoring are essential to prevent leaks and ensure safe operations. Facilities employing gas chlorine systems must also invest in robust safety equipment, such as gas detection systems and emergency response kits, to mitigate risks associated with chlorine exposure. Furthermore, regular maintenance and inspections are critical to ensure that all components of the system function correctly and that safety measures are up to date, thereby safeguarding both the workforce and the surrounding community.

The Process of Chlorine Injection

The process of injecting chlorine into water involves several key steps that ensure effective treatment while maintaining safety and compliance with regulations.

Pre-Injection Considerations

Before initiating chlorine injection, operators must carry out water quality testing to determine appropriate dosage levels. Factors to evaluate include pH, temperature, organic matter concentration, and presence of other chemicals.

These pre-injection analyses help in determining the specific chlorine demand of the water, which is critical for dosing accuracy and overall system performance. Additionally, understanding the source of the water and its historical quality data can provide insights into potential contaminants that may require special attention during treatment. For instance, water sourced from agricultural areas may have higher levels of organic matter and pesticides, necessitating a tailored approach to chlorine dosing to ensure effective disinfection without creating harmful byproducts.

The Injection Process

The actual injection process begins once testing and monitoring confirm that conditions are acceptable. Chlorine is carefully dosed into the water stream through the designated injection point, ensuring it mixes adequately for even distribution.

This mixing can occur passively through turbulence in the pipeline or through additional mixing mechanisms, depending on the system design. In some advanced systems, automated control technologies are employed to adjust the chlorine dosage in real-time based on ongoing water quality assessments. This dynamic approach not only enhances the effectiveness of disinfection but also minimizes the risk of over-chlorination, which can lead to unpleasant tastes and odors in the water.

Post-Injection Monitoring

After chlorine has been injected, continuous monitoring is crucial. Operators need to track residual chlorine levels to confirm that adequate disinfection has occurred without exceeding permissible limits.

Routine water sampling and analysis are essential components of post-injection monitoring, ensuring compliance with health regulations and maintaining the safety of the water supply. Furthermore, the implementation of advanced monitoring systems can provide real-time data analytics, allowing operators to quickly identify any deviations from expected chlorine levels. This proactive approach not only enhances the safety of the water but also contributes to more efficient operational practices by facilitating timely adjustments to the chlorine injection process as needed.

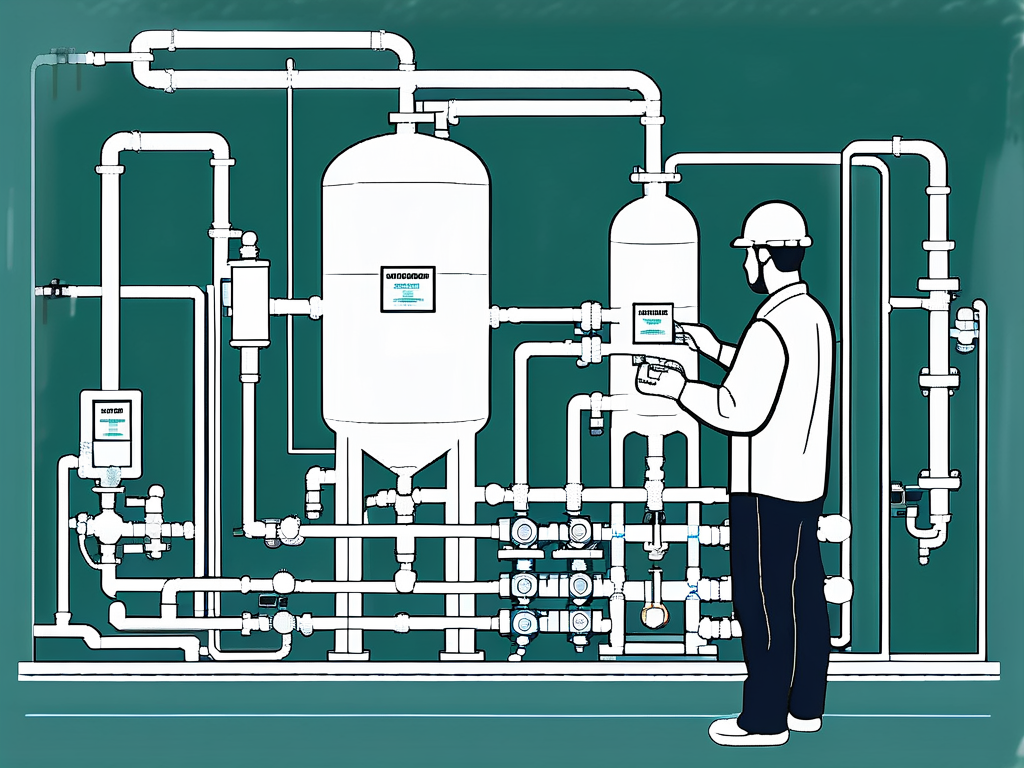

Maintenance of Chlorine Injection Systems

To ensure that chlorine injection systems perform optimally, rigorous maintenance is necessary. This includes both routine inspections and addressing any issues that may arise. Regular upkeep not only enhances the efficiency of the system but also plays a crucial role in ensuring the safety of water treatment processes.

Routine Maintenance Tasks

Regular maintenance tasks may encompass checking and calibrating flow meters, inspecting chlorinators for leaks, and replacing any worn or damaged components. Additionally, it's important to clean the injection points and verify that the chemical feed rate aligns with the requirements of the water being treated. This proactive approach can prevent larger issues down the line, ensuring that the system operates smoothly and effectively.

Documentation of maintenance activities is essential for compliance and helps in tracking any necessary repairs or upgrades to the system over time. Maintaining a detailed log not only assists in regulatory compliance but also serves as a valuable resource for identifying trends in system performance, which can inform future maintenance schedules and operational adjustments.

Troubleshooting Common Issues

Chlorine injection systems can face various operational challenges, including unexpected flow variations, equipment malfunctions, or incorrect dosing rates. Training personnel in troubleshooting practices is vital for minimizing downtime. A well-trained team can quickly identify and rectify issues, ensuring that water quality remains within safe parameters and that treatment processes are not disrupted.

Common troubleshooting steps include recalibrating equipment, checking for blockages in the injection line, and verifying that safety protocols are functioning correctly. Moreover, understanding the specific characteristics of the water being treated, such as pH levels and temperature, can aid in diagnosing problems more effectively. Implementing a systematic approach to troubleshooting can lead to more efficient resolutions and a deeper understanding of the system's operational dynamics, ultimately enhancing the reliability of chlorine injection systems.

Safety Measures for Handling Chlorine Injection Systems

Safety is paramount in the handling and management of chlorine injection systems. The hazardous nature of chlorine requires comprehensive safety measures to protect workers and the community.

Personal Protective Equipment

Operators must use appropriate personal protective equipment (PPE) when handling chlorine, which may include gloves, goggles, and respirators, depending on exposure risks. Regular training sessions are critical to ensure all personnel understand how to handle chlorine safely. Additionally, it is important to conduct routine inspections of PPE to ensure that it is in good condition and free from any damage that could compromise safety. Operators should also be trained to recognize the signs of chlorine exposure, such as respiratory distress or skin irritation, and know the immediate steps to take in such situations.

Safe Storage and Handling of Chlorine

Whether using gas or liquid chlorine, safe storage is essential. Chlorine storage areas must be well-ventilated, secure, and labeled clearly to minimize any accidental exposure or leaks. The storage facilities should be equipped with appropriate containment systems to manage any potential spills, and regular maintenance checks should be conducted to ensure that all equipment is functioning correctly. Furthermore, it is crucial to keep chlorine away from incompatible substances, such as ammonia or organic materials, to prevent dangerous reactions.

Established protocols for handling chlorine, including spill response plans, must be in place to address any emergencies swiftly and effectively. These plans should include detailed instructions on how to evacuate personnel safely, as well as how to notify emergency services. Regular drills should be conducted to ensure that all staff are familiar with these protocols and can act quickly and efficiently in the event of a chlorine leak or other emergency. Additionally, maintaining an inventory of emergency supplies, such as neutralizing agents and first aid kits, can significantly enhance the safety measures in place.

Environmental Impact of Chlorine Injection

The usage of chlorine in water treatment comes with environmental considerations that must be carefully managed to mitigate negative impacts.

Chlorine and Aquatic Life

While chlorine is essential for disinfecting water, it can pose a threat to aquatic life when it enters natural water bodies. Unmonitored chlorine levels can lead to toxicity, harming fish and other organisms. For instance, species such as salmon and trout are particularly sensitive to chlorine exposure, which can impair their respiratory systems and disrupt their reproductive cycles. Additionally, the presence of chlorine can alter the composition of aquatic ecosystems, favoring the survival of certain species over others, thus diminishing biodiversity and destabilizing food webs.

Chlorine Byproducts and Their Effects

The reaction of chlorine with organic materials in water can lead to the formation of disinfection byproducts (DBPs), which may be harmful to human health. Regulatory agencies have established guidelines to limit DBP levels, requiring facilities to implement strategies to minimize their generation. These strategies may include optimizing the chlorine dosage, using alternative disinfection methods such as UV treatment, or employing advanced filtration techniques. Furthermore, research is ongoing to better understand the long-term health implications of DBPs, as studies have linked certain byproducts to increased risks of cancer and reproductive issues. As a result, water treatment facilities are under pressure to adopt innovative technologies and practices that not only ensure safe drinking water but also protect the surrounding environment.

Future Trends in Chlorine Injection Systems

As water treatment technologies evolve, so too do the methodologies surrounding chlorine injection systems. Keeping abreast of future trends will help facilities ensure compliance and effectiveness.

Technological Advancements

Ongoing research and development are leading to more sophisticated chlorine injection systems that utilize automation and advanced control technologies. These developments promise improved reliability, better monitoring systems, and more precise dosing capabilities. For instance, the integration of IoT (Internet of Things) technology allows for real-time data collection and analysis, enabling operators to make informed decisions quickly. Furthermore, the implementation of machine learning algorithms can predict maintenance needs, thus minimizing downtime and enhancing operational efficiency.

Regulatory Changes and Their Impact

As environmental regulations continue to evolve, water treatment facilities must remain adaptable to new guidelines governing chlorine use and resulting byproducts. Staying informed and compliant will be crucial for effective water treatment in the years to come. Additionally, the shift towards more sustainable practices is prompting facilities to explore alternative disinfection methods that may complement or even replace traditional chlorine injection systems. This includes the use of UV light and ozone treatment, which can reduce harmful byproducts while maintaining water quality. The interplay between these emerging technologies and chlorine systems will likely shape the future landscape of water treatment.

Moreover, the growing emphasis on public health and safety is driving innovations in chlorine injection systems. Enhanced public awareness regarding water quality issues has led to increased scrutiny of water treatment processes. As a result, facilities are investing in advanced filtration and monitoring technologies to ensure that chlorine levels remain within safe limits. This proactive approach not only helps in maintaining compliance with regulations but also builds public trust in the safety of drinking water. By leveraging these advancements, water treatment facilities can better respond to the evolving needs of communities, ensuring a consistent supply of safe and clean water.