Understanding Chlorine Injectors: A Comprehensive Guide

Chlorine injectors play a critical role in water treatment processes across various industries, ensuring that water is safe and free from harmful pathogens. This comprehensive guide will take you through the essentials of chlorine injectors, their types, working principles, installation and maintenance practices, safety measures, troubleshooting techniques, and future trends in technology.

The Basics of Chlorine Injectors

Understanding the fundamentals of chlorine injectors is crucial for those involved in water treatment. These devices are designed to introduce chlorine into water systems, effectively promoting sanitation and disinfection. By studying the principles behind chlorine injectors, users can appreciate their significance and functionality in various applications. Moreover, a deeper comprehension of these systems can lead to better maintenance practices and improved water quality outcomes.

What is a Chlorine Injector?

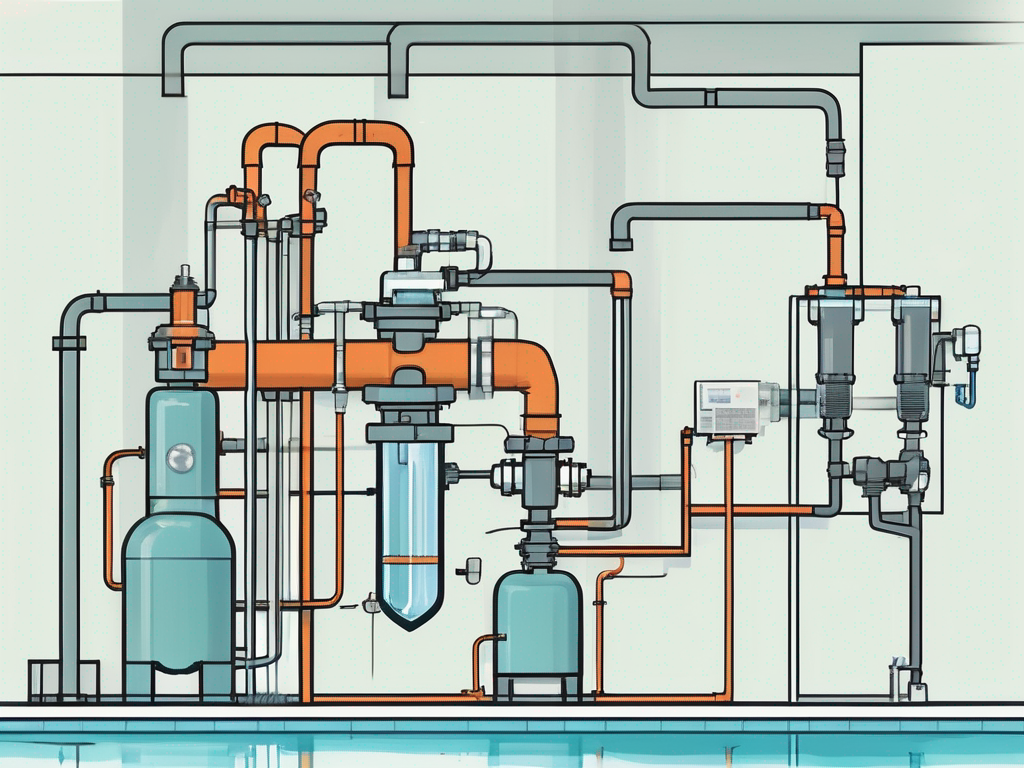

A chlorine injector is a mechanical device that facilitates the injection of chlorine, either in liquid or gas form, into a water supply to achieve desired chlorine levels. The process of injection ensures that chlorine molecules are evenly dispersed throughout the water, optimizing the treatment efficiency. Typically used in municipal water systems, swimming pools, and industrial applications, chlorine injectors are essential for maintaining water quality. The design of these injectors can vary, with some utilizing venturi systems to create a vacuum that draws chlorine into the water stream, while others may employ diaphragm pumps for precise control over chlorine dosage.

Importance of Chlorine Injectors

Chlorine injectors are vital for several reasons:

- Effective Disinfection: They help in eliminating bacteria, viruses, and other pathogens in water, thus safeguarding public health.

- Odor and Taste Improvement: Chlorine treatment improves the sensory qualities of water, making it more palatable.

- Cost-Effectiveness: By using chlorine injectors, facilities can manage water quality efficiently, reducing the need for extensive manual interventions.

In addition to these benefits, chlorine injectors play a significant role in regulatory compliance. Many regions have strict guidelines regarding water quality, and chlorine injection systems help facilities meet these standards consistently. Furthermore, the automation of chlorine dosing through these injectors minimizes human error, ensuring that the right amount of chlorine is always present in the water supply. This reliability is particularly crucial in larger systems where fluctuations in water demand can occur, necessitating a responsive and adaptable treatment approach.

Another noteworthy aspect of chlorine injectors is their contribution to the overall efficiency of water treatment processes. By maintaining optimal chlorine levels, these devices not only enhance disinfection but also reduce the formation of harmful byproducts that can arise from inadequate treatment. This is especially important in swimming pools, where the balance of chlorine must be carefully monitored to ensure a safe and enjoyable environment for users. Additionally, the integration of advanced monitoring technologies with chlorine injectors allows for real-time adjustments, further optimizing the water treatment process and ensuring that safety standards are consistently met.

Types of Chlorine Injectors

Chlorine injectors are categorized primarily based on the form of chlorine they utilize, which can influence their application and operation.

Liquid Chlorine Injectors

Liquid chlorine injectors are the most common type, utilizing sodium hypochlorite or calcium hypochlorite. These devices are straightforward and easy to operate, ensuring precise metering of chlorine into water systems. They generally require a feed line connected to a liquid chlorine storage tank, maintaining consistent dosing. Their simplicity makes them a preferred choice for many facilities. Additionally, liquid chlorine injectors can be easily integrated into existing water treatment systems, making them a versatile option for both municipal and industrial applications. They are particularly favored in smaller facilities due to their user-friendly nature and lower initial investment costs.

Moreover, the effectiveness of liquid chlorine injectors in maintaining desired chlorine levels in water systems cannot be overstated. They allow for real-time adjustments based on water quality parameters, ensuring that the disinfection process is both efficient and effective. This adaptability is crucial in environments where water quality can fluctuate, such as swimming pools or wastewater treatment plants. Furthermore, advancements in technology have led to the development of automated liquid chlorine injectors, which can monitor and adjust chlorine levels without manual intervention, enhancing operational efficiency and safety.

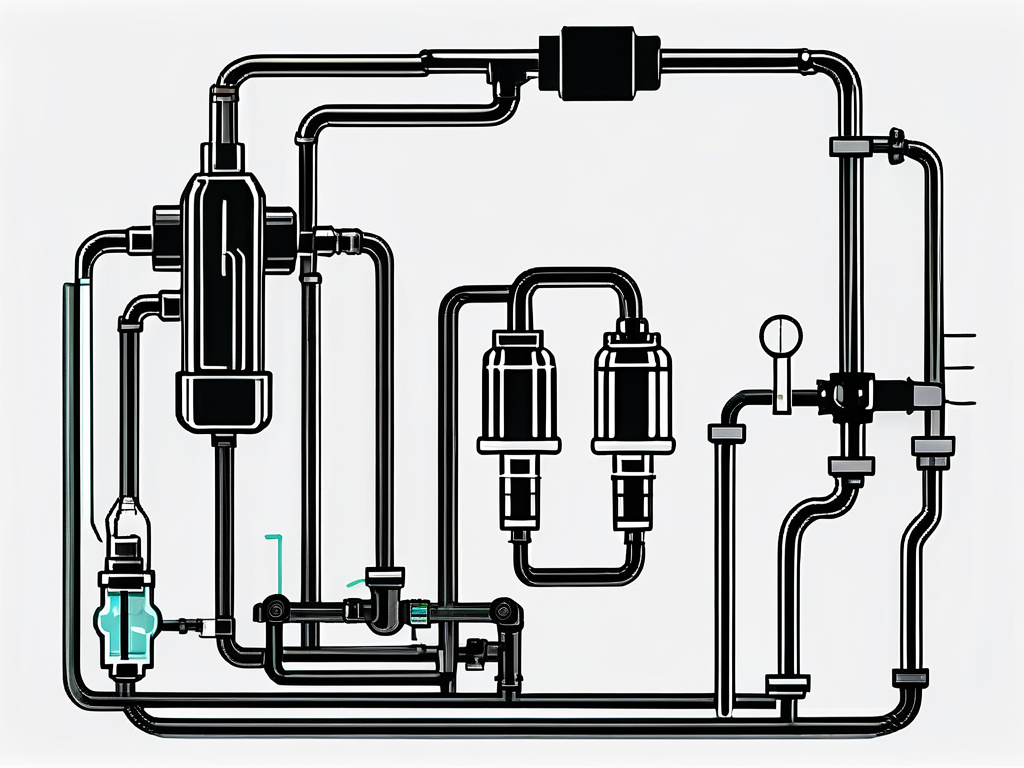

Gas Chlorine Injectors

Gas chlorine injectors, on the other hand, inject chlorine gas directly into the water. This type of injectors requires careful handling and safety considerations because chlorine gas is highly toxic. Gas chlorine systems are typically more cost-effective for larger-scale applications, as they require fewer storage and maintenance needs than liquid systems. In addition to their economic advantages, gas chlorine injectors can achieve higher levels of disinfection, making them suitable for large municipal water treatment facilities where high volumes of water need to be treated rapidly.

However, the use of gas chlorine injectors necessitates stringent safety protocols, including the installation of gas detection systems and proper ventilation to mitigate the risks associated with chlorine gas exposure. Training for personnel handling these systems is also crucial to ensure compliance with safety regulations. Furthermore, the infrastructure required for gas chlorine systems can be more complex, often involving specialized equipment such as vacuum regulators and gas scrubbers. Despite these challenges, the efficiency and effectiveness of gas chlorine injectors make them a vital component in the toolkit of water treatment professionals, particularly in large-scale operations where maintaining water quality is of utmost importance.

Working Principle of Chlorine Injectors

The effective operation of chlorine injectors hinges on a well-understood working principle that ensures optimal performance.

The Injection Process

The injection process begins when water flows through the injector, creating negative pressure that draws chlorine into the water stream. The injector is designed to mix the chlorine thoroughly with the water, ensuring an even distribution. The amount of chlorine injected can be controlled using varying methods, including flowmeters and control panels, allowing for precise adjustments. This level of control is essential, as it enables operators to tailor the chlorine dosage based on specific water quality parameters, such as turbidity or organic load, which can fluctuate throughout the day.

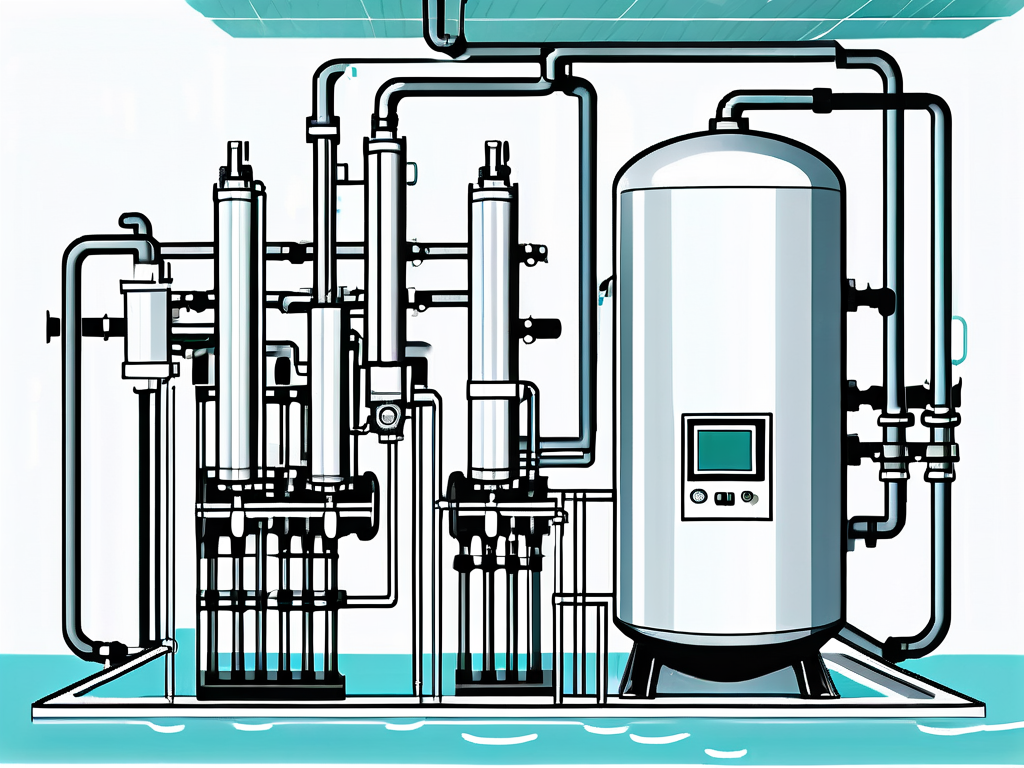

Chlorine Dissolution and Distribution

Once chlorine is injected, its dissolution in the water occurs swiftly. Proper dissolution is crucial for achieving effective disinfection. Afterward, the chlorinated water is distributed through the system, with monitoring mechanisms in place to ensure consistent chlorine levels throughout, thus maintaining water quality. Advanced systems often incorporate real-time sensors that provide feedback on chlorine residuals, allowing for immediate adjustments to be made if levels fall outside of the desired range. This proactive approach not only enhances the safety of the water supply but also optimizes the use of chlorine, reducing waste and minimizing the potential for harmful byproducts.

Importance of Maintenance

Regular maintenance of chlorine injectors is vital to ensure their longevity and effectiveness. Over time, components such as valves and seals can wear out, potentially leading to leaks or inconsistent chlorine dosing. Scheduled inspections and routine cleaning can help prevent these issues, ensuring that the injectors operate at peak efficiency. Additionally, operators should be trained to recognize the signs of malfunction, such as unusual pressure readings or fluctuating chlorine levels, which could indicate the need for immediate attention. By prioritizing maintenance, water treatment facilities can safeguard their processes and ensure that they continue to provide safe, high-quality water to their communities.

Installation and Maintenance of Chlorine Injectors

To ensure longevity and efficiency, proper installation and routine maintenance of chlorine injectors are essential.

Choosing the Right Location for Installation

Location selection for installing chlorine injectors can greatly influence their functionality. Ideally, these devices should be installed close to where water is treated to minimize the distance chlorine must travel. Accessibility for maintenance and monitoring is also critical, so installers must consider both operational efficiency and safety when choosing a site. Additionally, it is important to ensure that the installation area is well-ventilated and protected from extreme weather conditions, as excessive heat or moisture can adversely affect the performance of the injector. Proper drainage should also be considered to prevent any potential flooding that could damage the equipment or compromise safety.

Routine Maintenance Tips

Routine maintenance ensures that chlorine injectors perform optimally. Regular checks should be conducted to monitor wear and tear on components. Key maintenance activities include:

- Inspecting and replacing seals and gaskets to prevent leaks.

- Cleaning the injectors regularly to avoid buildup that may affect performance.

- Calibrating the injector for accurate dosing to ensure consistent chlorination.

In addition to these tasks, operators should also keep a detailed maintenance log that tracks all inspections, repairs, and replacements. This documentation can help identify patterns over time, allowing for proactive measures to be taken before issues escalate. Furthermore, it is advisable to schedule professional inspections at least once a year, as trained technicians can provide insights and identify potential problems that may not be apparent during routine checks. By prioritizing both preventive and corrective maintenance, facilities can significantly extend the lifespan of their chlorine injectors and maintain optimal water quality standards.

Safety Measures for Using Chlorine Injectors

Safety is paramount when dealing with chlorine injectors due to the potential hazards associated with chlorine.

Handling Chlorine Safely

Proper handling of chlorine involves training personnel on safety protocols and providing appropriate personal protective equipment (PPE). Operators should also be aware of the symptoms of chlorine exposure and trained to react promptly to any leaks or spills. This includes understanding the importance of wearing gloves, goggles, and respiratory protection when working with chlorine. Additionally, it is vital to establish clear communication channels among team members to ensure that everyone is aware of their roles in maintaining safety during operations.

Furthermore, regular safety drills can reinforce the knowledge and preparedness of staff. These drills should simulate various scenarios, such as a chlorine leak or equipment failure, allowing personnel to practice their responses in a controlled environment. By fostering a culture of safety and vigilance, organizations can significantly reduce the risk of accidents and enhance the overall safety of chlorine handling operations.

Preventing and Managing Leaks

Implementing leak detection systems is an effective preventive measure. Regularly monitoring sensors and alarms can help identify leaks before they escalate into dangerous situations. In case of a leak, it is crucial to follow an emergency response plan, which may include evacuating personnel and notifying emergency services. This plan should be well-documented and accessible to all employees, ensuring that everyone knows the steps to take in an emergency.

In addition to leak detection systems, routine maintenance of equipment is essential to prevent leaks from occurring in the first place. Scheduled inspections can help identify wear and tear on hoses, fittings, and injectors, allowing for timely repairs or replacements. Moreover, keeping a detailed log of maintenance activities can provide valuable insights into the performance of the system and highlight any recurring issues that need addressing. By prioritizing both proactive and reactive measures, organizations can create a safer working environment when using chlorine injectors.

Troubleshooting Common Chlorine Injector Problems

Every chlorination system might encounter challenges that require troubleshooting for resolution.

Injector Not Working

One common issue is when the injector fails to operate. This can be due to blockages in the lines, insufficient vacuum pressure, or mechanical failures. Regular checks and maintaining a clear flow path can help mitigate this issue. Testing components can also assist in identifying electrical or mechanical faults that may require repair. Additionally, it's important to inspect the injector's diaphragm and check for signs of wear or damage, as a compromised diaphragm can significantly hinder performance. Cleaning the injector regularly and ensuring that all connections are secure can further prevent operational disruptions.

Inadequate Chlorination

Inadequate chlorination can stem from various sources, such as improper settings, malfunctioning flow meters, or chemical supply issues. It is crucial to establish regular monitoring procedures to ensure effective chlorine levels are consistently maintained. In cases of inadequate chlorination, immediate assessment and corrective actions are needed to restore efficient operation. Furthermore, understanding the specific water chemistry and adjusting the chlorination system accordingly can enhance effectiveness. For instance, factors such as pH levels, temperature, and the presence of organic matter can all influence chlorine demand, so a comprehensive analysis of these variables should be part of routine maintenance to ensure optimal chlorination performance.

Future Trends in Chlorine Injection Technology

As technology evolves, newer and more efficient methods of chlorine injection are being developed to enhance water treatment processes.

Innovations in Chlorine Injection

Emerging technologies such as smart sensors and automated control systems are revolutionizing chlorine injection methods. These innovations allow for real-time monitoring and adjustments to chlorine levels, improving overall system responsiveness and reducing waste. Furthermore, advancements in data analytics enable operators to predict chlorine demand based on usage patterns and environmental conditions, leading to more precise dosing and enhanced system efficiency. This not only optimizes the chemical usage but also contributes to cost savings for water treatment facilities.

Environmental Impact and Sustainability

The focus on sustainability has led to developments aimed at reducing the environmental impact of chlorine use. Newer technologies emphasize reducing chemical usage, enhancing safety features, and improving energy efficiency, making chlorine injection systems more environmentally friendly while retaining effectiveness. Additionally, there is a growing trend towards integrating alternative disinfection methods, such as ultraviolet (UV) light and ozone, which can work in tandem with chlorine injection to minimize chemical reliance while ensuring water safety. These hybrid approaches not only improve the overall treatment process but also address public health concerns regarding disinfection by-products associated with chlorine use.

Moreover, the push for regulatory compliance and public transparency has prompted the development of systems that provide detailed reporting on chlorine levels and water quality. This transparency fosters community trust and ensures that water treatment facilities are held accountable for maintaining high standards. As these technologies continue to evolve, they promise to create a more resilient and adaptable water treatment infrastructure, capable of meeting the challenges posed by climate change and population growth.

In conclusion, understanding chlorine injectors and their implementation is essential for effective water treatment. With proper knowledge of their types, operation, installation, maintenance, and safety measures, users can ensure reliable performance and enhance water quality in various applications.