Understanding Lift Station Tanks: Essential Components and Maintenance Tips

Understanding Lift Station Tanks: Essential Components and Maintenance Tips

Lift station tanks are critical components in modern wastewater management systems. They serve the essential function of transferring sewage and stormwater from lower to higher elevations, ensuring effective drainage and treatment. To fully understand lift station tanks, it's crucial to explore their structure, components, maintenance needs, and the challenges they may face.

What is a Lift Station Tank?

A lift station tank is a subterranean facility designed to collect and pump wastewater and sewage. Positioned in strategic locations, these tanks address elevation challenges in sewer systems. Without lift station tanks, gravity alone would be insufficient to transport waste in areas with varied topography. These tanks are especially crucial in regions where natural slopes do not favor the flow of wastewater, such as flat urban areas or locations with significant underground infrastructure.

Generally constructed from durable materials, lift station tanks come in various sizes and configurations, depending on the specific requirements of the installation site. Their significant role in preventing sewage backups and environmental hazards makes them essential for any efficient urban infrastructure. Moreover, the design of these tanks often incorporates advanced technology, including automated controls and monitoring systems, which enhance their operational efficiency and reliability. This technological integration allows for real-time data collection, enabling operators to respond swiftly to any issues that may arise.

The Role of Lift Station Tanks in Waste Management

Lift station tanks play a pivotal role in effective waste management by facilitating the movement of sewage to treatment plants, which helps prevent overflows and contamination. By pumping wastewater from lower elevations to higher ground, they also aid in maintaining effective pressure levels within the sewer system. This is particularly important during heavy rainfall or snowmelt, when the volume of wastewater can surge dramatically, potentially overwhelming the system.

Additionally, lift station tanks can help to buffer fluctuations in wastewater flow, ensuring that treatment facilities receive a consistent and manageable volume of water. This process protects both public health and the environment by improving the reliability and safety of sewage transportation. Furthermore, many modern lift stations are equipped with odor control systems and advanced filtration technologies, which mitigate unpleasant smells and enhance the overall sanitation of the surrounding area. Such features contribute to a more pleasant living environment for nearby residents, highlighting the importance of thoughtful design in urban waste management systems.

Different Types of Lift Station Tanks

There are several types of lift station tanks, each designed to suit particular needs and conditions. The most common types include:

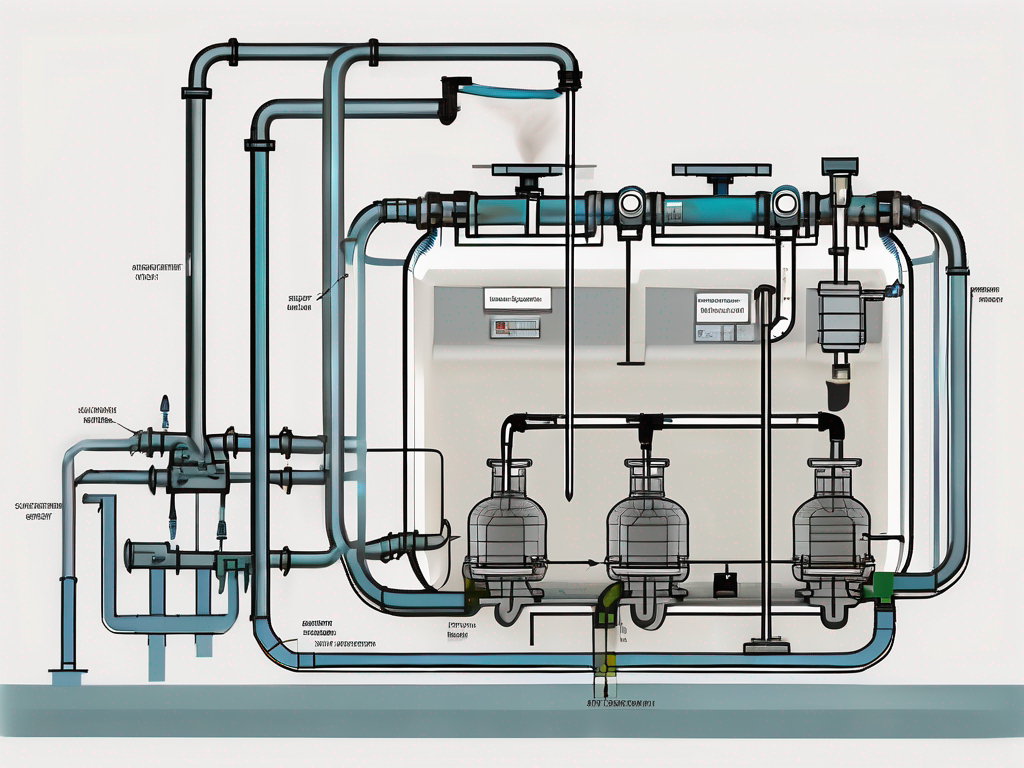

- Submersible Lift Stations: These stations contain pumps located below the surface of the wastewater. They are often used when space is limited or when noise reduction is necessary. Their compact design allows for installation in tight urban spaces, making them ideal for densely populated areas.

- Dry Pit Lift Stations: In this setup, pumps are situated above the wastewater level in a separate chamber, allowing for easier maintenance and repair. This design is beneficial in situations where frequent access to the pumps is required, as it minimizes the need for personnel to enter potentially hazardous environments.

- Split Station Assemblies: These consist of a wet well and a dry well, enabling greater flexibility in pump selection and maintenance options. This configuration allows for the simultaneous operation of multiple pumps, which can be crucial during peak flow periods.

Each type has its benefits and considerations, allowing engineers to select the most appropriate solution based on site-specific conditions. Additionally, the choice of lift station tank can impact the overall efficiency of the wastewater management system, influencing factors such as energy consumption, operational costs, and maintenance requirements. As cities continue to grow and evolve, the importance of selecting the right type of lift station tank becomes increasingly critical to ensure sustainable and effective waste management practices.

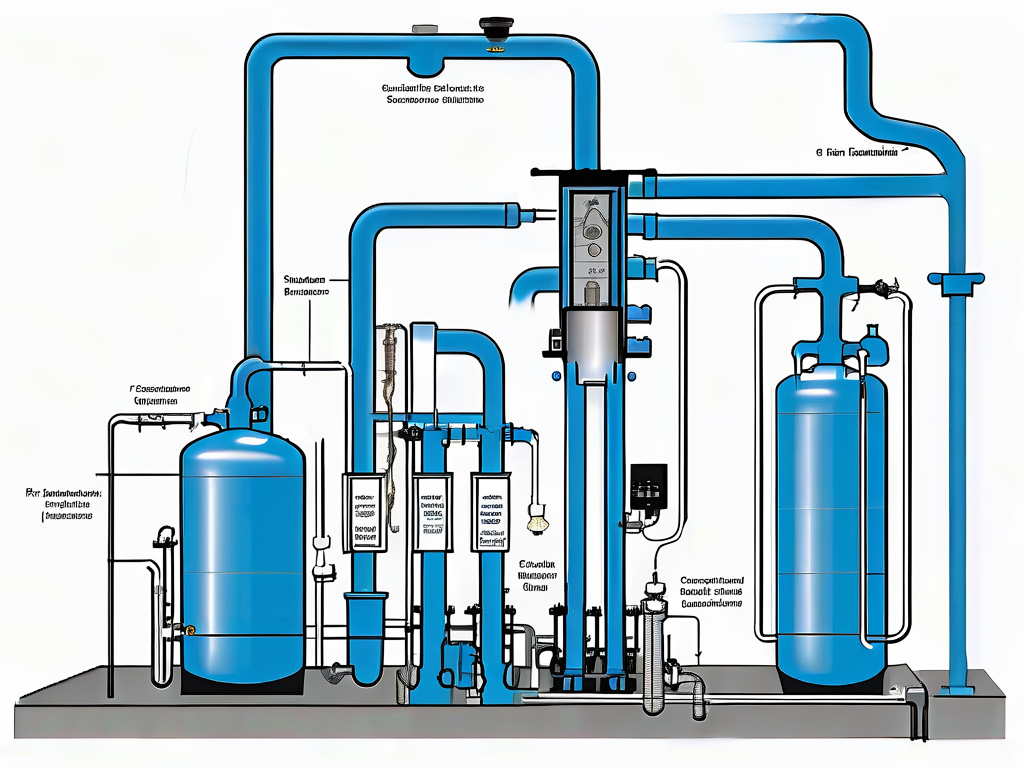

Essential Components of a Lift Station Tank

Understanding the various components of a lift station tank is essential for ensuring its longevity and functionality. A well-structured tank consists of several crucial elements that work together to provide a seamless sewage management system.

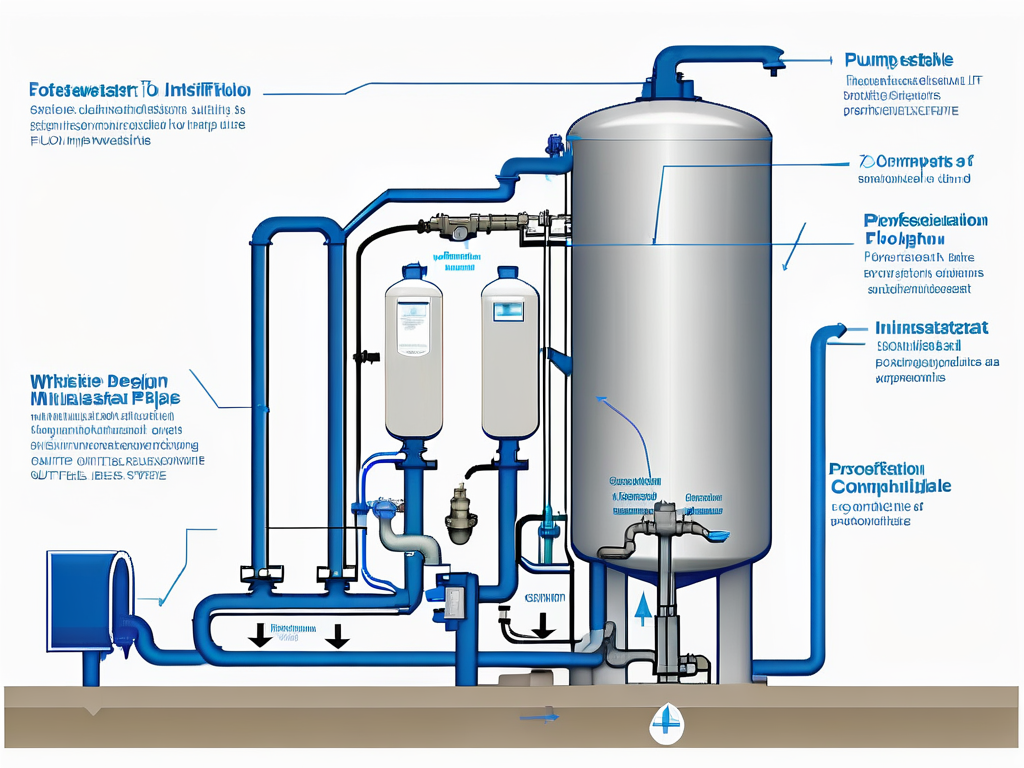

Pumps and Valves

Pumps are the heart of a lift station tank, responsible for moving wastewater from the tank to the treatment facility. These pumps require careful selection based on flow rate, head pressure, and operational conditions. Valves, on the other hand, regulate the flow and pressure within the system, providing crucial control over the pumping process.

Regular inspection and maintenance of pumps and valves are essential to prevent failures and ensure operational efficiency. Additionally, the choice between submersible and dry pit pumps can significantly impact the maintenance requirements and overall performance of the lift station. Submersible pumps are often preferred for their compact design and reduced noise levels, while dry pit pumps may offer easier access for repairs and inspections. Understanding the specific needs of the installation site can guide operators in making the best selection.

Control Panel

The control panel serves as the operational center for the lift station tank, allowing users to monitor and manage various functions, including pump cycles, alarms, and power supply. Equipped with various controls, the panel not only provides real-time data but also enables quick responses to any system failures or emergencies.

Investing in a reliable control panel can significantly enhance the effectiveness of a lift station tank, facilitating smooth operations and timely alerts. Advanced control panels may also feature remote monitoring capabilities, allowing operators to oversee the system from a distance. This can be particularly beneficial in rural or hard-to-access areas, where immediate on-site inspection may not be feasible. Furthermore, integrating smart technology can lead to predictive maintenance, where data analytics help forecast potential failures before they occur.

Wet Well

The wet well is the primary chamber of the lift station where wastewater gathers before being pumped out. Proper design and sizing of the wet well are fundamental to ensure efficient flow dynamics and enough storage capacity to handle peak inflow conditions.

Moreover, the wet well needs periodic cleaning and inspection to prevent the accumulation of debris and sludge, which can lead to operational issues. The installation of level sensors can enhance the management of the wet well by providing accurate readings of wastewater levels, thus optimizing pump operation. Additionally, incorporating odor control measures, such as ventilation systems or chemical treatments, can mitigate unpleasant smells that may arise from the wet well, improving the surrounding environment and community satisfaction.

Power Supply

A stable and reliable power supply is essential for the continuous operation of lift station tanks. Power disruptions can lead to sewage backups, creating environmental risks. Many modern installations include backup generators and alternative power sources to maintain functionality during outages.

Regular testing of power supply systems ensures that any potential issues are addressed proactively, thereby maintaining the tank’s operational readiness. Furthermore, implementing energy-efficient technologies can reduce operational costs and environmental impact. Solar panels or wind turbines may be integrated into the power supply system, providing a sustainable energy source that can lessen reliance on traditional power grids. This not only enhances the resilience of the lift station but also aligns with broader sustainability goals in wastewater management.

The Importance of Regular Maintenance

Regular maintenance is vital to ensure the optimal performance and longevity of lift station tanks. Failure to maintain these systems can lead to severe consequences, including costly repairs and environmental damage.

Extending the Lifespan of Your Lift Station Tank

Scheduled maintenance activities, including inspections and equipment servicing, can drastically extend the lifespan of a lift station tank. By identifying and resolving issues before they escalate, operators can significantly reduce replacement costs and enhance overall system reliability.

This proactive approach not only promotes sustainability but also contributes to more efficient waste management practices. Additionally, regular maintenance can improve energy efficiency, as well-maintained equipment operates more smoothly and requires less power to function. This not only reduces operational costs but also lessens the environmental footprint associated with energy consumption.

Preventing System Failures

Regular maintenance helps to identify potential system failures early. Through routine checks on critical components such as pumps, valves, and electrical systems, operators can mitigate the risk of equipment breakdowns that could disrupt sewage transport.

Failing to conduct regular maintenance can lead to unplanned outages, resulting in emergency situations that are often more expensive to resolve. Moreover, these outages can pose significant public health risks, as untreated sewage can overflow and contaminate surrounding areas. Implementing a comprehensive maintenance schedule not only safeguards the infrastructure but also protects the community from the adverse effects of sewage spills, ensuring a cleaner and safer environment for all.

Maintenance Tips for Lift Station Tanks

To ensure the efficiency and the longevity of lift station tanks, specific maintenance practices should be implemented consistently. Here are some key tips:

Regular Cleaning and Inspection

Routine cleaning of the wet well and the overall tank is crucial to remove any buildup of sludge or debris. Inspections should include checking for leaks, obstructions, and the condition of critical components.

Developing a regular cleaning schedule not only prolongs equipment life but also maintains effective hydraulic operation. It is advisable to document each cleaning and inspection session, noting any irregularities or maintenance performed. This log can be invaluable for tracking the performance of the lift station over time and can help identify patterns that may indicate underlying issues.

Proper Lubrication of Components

Ensuring that all moving parts, such as pumps and valves, are adequately lubricated helps minimize wear and tear. This maintenance step is critical in reducing friction, preventing overheating, and enhancing overall efficiency.

Regular lubrication intervals should be developed based on manufacturer specifications to achieve the best results. Furthermore, using the correct type of lubricant is essential; different components may require specific lubricants to function optimally. Keeping an inventory of lubrication supplies and scheduling periodic reviews can help ensure that all necessary materials are on hand and that lubrication practices are adhered to consistently.

Alarm System Checks

A reliable alarm system is vital for detecting potential issues within the lift station tank. Regularly testing and verifying the function of alarms ensures that operators are alerted immediately in case of a malfunction.

Routine checks can include verifying alarm thresholds and response mechanisms, thereby enhancing system reliability. Additionally, training staff on the proper response to alarm notifications can significantly reduce response times during emergencies. Implementing a protocol for alarm testing, including a checklist of items to verify, can streamline the process and ensure thoroughness in each check.

Professional Maintenance Services

While routine maintenance can be conducted by in-house personnel, engaging professional maintenance services ensures a higher level of expertise in handling complex systems. Trained technicians can perform comprehensive assessments, providing peace of mind regarding the operational integrity of lift station tanks.

Investing in professional services can uncover issues that may not be immediately visible during basic inspections. These experts often utilize advanced diagnostic tools and techniques, such as thermal imaging and vibration analysis, to detect potential problems before they escalate. Establishing a partnership with a reputable maintenance provider can also facilitate ongoing training for in-house staff, ensuring that they remain updated on best practices and new technologies in lift station management.

Troubleshooting Common Lift Station Tank Issues

Understanding common issues that can arise with lift station tanks is essential for effective management and maintenance. Here are some prevalent problems and their potential solutions:

Pump Failures

Pump failures are one of the most common issues faced by lift station tanks. These can occur due to various reasons, including electrical faults, blockages, or mechanical issues. Regular inspection and maintenance greatly reduce the risk of unexpected pump failures.

Having a backup pump can also provide operational continuity and serve as a contingency measure when primary pumps fail. Furthermore, implementing a predictive maintenance program that utilizes data analytics can help identify wear patterns and potential failure points before they become critical. This proactive approach not only extends the life of the pumps but also ensures that the lift station operates smoothly, reducing the likelihood of costly emergency repairs.

Electrical Problems

Electrical issues can range from simple blown fuses to more complex control panel malfunctions. Regular testing of electrical components and maintaining a well-structured power supply system will minimize risks associated with electrical failures.

Additionally, ensuring proper grounding and surge protection can help safeguard against electrical anomalies. It is also beneficial to keep an updated electrical schematic on hand, as this can expedite troubleshooting during a failure. Training staff on basic electrical diagnostics can further enhance the team's ability to respond quickly to electrical issues, ensuring minimal downtime and maintaining the integrity of the lift station's operations.

Clogs and Blockages

Clogs can occur due to debris accumulating in the wet well or pumps. Regular cleaning and inspection are necessary to prevent blockages from disrupting flow and affecting the overall system. Operators should also educate users about what materials should not be flushed to reduce the likelihood of clogs.

Developing a proactive monitoring strategy can significantly reduce the risk of unexpected blockages, thereby maintaining operational efficiency. Utilizing advanced technologies such as remote monitoring systems can provide real-time data on flow rates and levels within the tank, alerting operators to potential issues before they escalate. Additionally, implementing a routine maintenance schedule that includes video inspections can help identify problem areas within the system, allowing for timely interventions and reducing the frequency of emergency situations.

Safety Measures When Handling Lift Station Tanks

Safety must be a priority when dealing with lift station tanks. Workers face numerous risks that require the implementation of appropriate safety measures to foster a secure working environment.

Protective Gear

Personal protective equipment (PPE) is essential when working near lift station tanks. Staff should wear suitable clothing, including gloves, goggles, and hard hats to prevent injuries from potential hazards.

Equip personnel with safety harnesses when working in confined spaces to minimize risks associated with accidental falls or equipment failures. Additionally, high-visibility vests should be worn to ensure that workers are easily seen in low-light conditions or when operating near heavy machinery. This not only enhances individual safety but also promotes a culture of awareness among team members, which is crucial in high-risk environments.

Safe Handling of Electrical Components

Electrical components should always be handled with care. Technicians must be trained in safe practices for working with electrical systems, including proper lockout/tagout procedures to prevent accidental energization.

Ensuring that all staff are familiar with safe handling practices will minimize the risks associated with electrical faults within the lift station tank. Furthermore, regular inspections of electrical equipment should be conducted to identify any signs of wear or damage that could lead to malfunctions. Implementing a routine maintenance schedule not only enhances safety but also extends the lifespan of the equipment, reducing the likelihood of unexpected failures during operation.

Emergency Response Plan

Having a clear emergency response plan is critical in case of unexpected incidents related to lift station tanks. This plan should include defined roles and procedures for tackling various emergencies, including pump failures, spills, or electrical failures.

Regular drills and training sessions can help ensure that all staff members are prepared to respond correctly in an emergency, helping to mitigate the effects of any incident. Additionally, it is beneficial to establish communication protocols that outline how to report emergencies swiftly and efficiently. This ensures that help can be mobilized quickly, potentially reducing the impact of the incident on both personnel and the environment. Moreover, maintaining an updated inventory of emergency supplies, such as spill containment kits and first aid materials, is essential for effective response during critical situations.

In conclusion, understanding lift station tanks, their essential components, maintenance tips, and safety measures can lead to better management practices and improved wastewater handling. Implementing these maintenance strategies and safety precautions will not only enhance the functionality of these systems but also safeguard public health and the environment.