Understanding Lift Stations: Essential Components and Maintenance Tips

Lift stations play a crucial role in the management of wastewater and stormwater systems. They are specially designed structures used to convey sewage from lower to higher elevations, ensuring that the wastewater is transported efficiently to treatment facilities. This article delves into what lift stations are, their key components, maintenance best practices, safety protocols, and future advancements in this vital area of infrastructure.

What are Lift Stations?

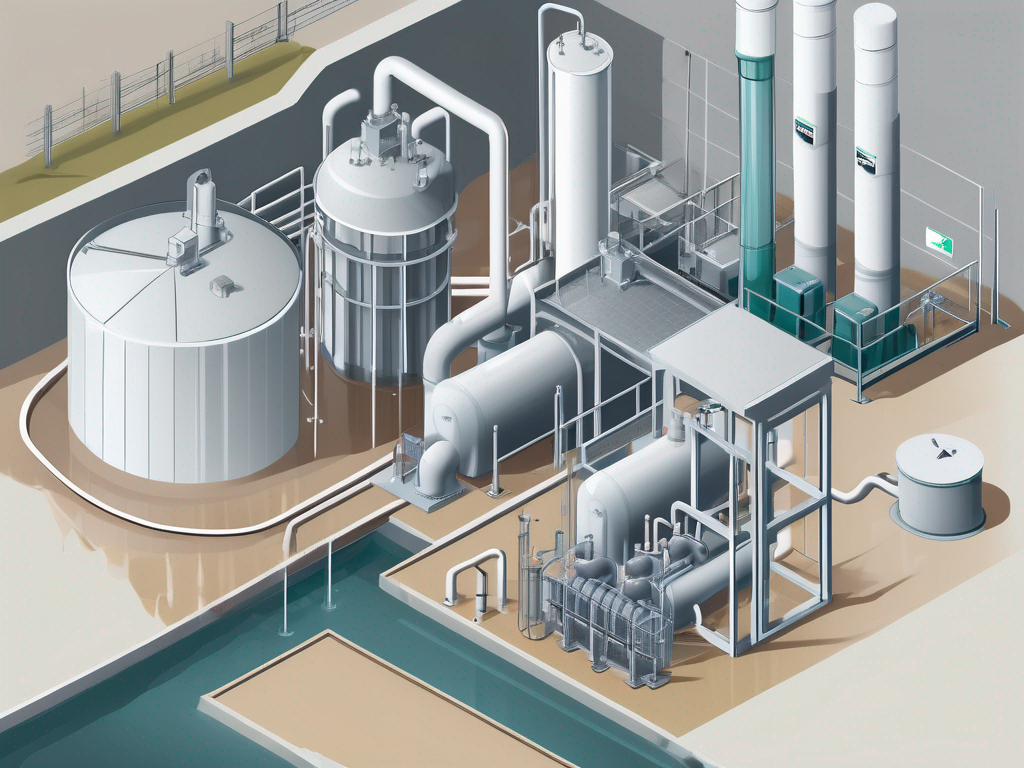

Lift stations are integral parts of modern wastewater management systems, facilitating the movement of sewage and wastewater through various terrains. They are typically located in areas where natural flow cannot adequately convey waste either due to topographical challenges or compressions of existing systems.

The Function and Importance of Lift Stations

The primary function of a lift station is to transport wastewater from a lower to a higher elevation. This is particularly important in urban settings where gravity alone cannot facilitate effective wastewater flow. By doing so, lift stations prevent sewage backups, protect public health, and maintain environmental integrity.

Beyond just moving water, lift stations also help manage pollution by ensuring that wastewater is directed to treatment plants efficiently. Their presence can significantly reduce the risk of overflows and contamination of local waterways. Moreover, lift stations are equipped with various monitoring systems that provide real-time data on flow rates and pump performance, allowing for proactive maintenance and minimizing the risk of unexpected failures. This technological integration enhances the overall reliability of wastewater systems, which is crucial for densely populated areas.

Different Types of Lift Stations

There are primarily two types of lift stations: wet and dry. Wet lift stations have pumps located below the water level, which can be beneficial in certain conditions. In contrast, dry lift stations house the pumps above the ground, making maintenance easier. Each type has its advantages and is chosen based on specific site conditions, including space availability and the nature of the wastewater being managed.

Additionally, lift stations can be designed for specific purposes, such as sewage or stormwater lifting, based on their operational requirements and the types of waste being handled. For instance, stormwater lift stations are often equipped with features to handle debris and sediment, ensuring that the pumps remain operational even during heavy rainfall. The design and construction of these stations must also consider factors such as energy efficiency and environmental impact, leading to innovations in pump technology and energy recovery systems that can harness the kinetic energy of flowing wastewater.

Essential Components of a Lift Station

Understanding the key components of a lift station is essential for effective operation and maintenance. Each element serves a critical role in ensuring smooth functionality and reliability.

Control Panel and Alarms

The control panel of a lift station is the brain of the operation. It monitors the system's status, controls the pumps, and houses alarms that signal operational issues. A reliable control panel ensures that all system components work harmoniously and alerts personnel to any electrical or mechanical failures.

Modern control panels often incorporate smart technology to provide real-time data, making it easier to manage the station remotely and effectively respond to issues as they arise. These advanced systems can also integrate with other municipal monitoring systems, allowing for a comprehensive overview of the wastewater management process. Furthermore, the ability to receive alerts via mobile devices enhances the responsiveness of maintenance teams, ensuring that any potential problems are addressed swiftly to prevent costly downtime.

Pumps and Valves

Pumps are the beating heart of a lift station, responsible for moving wastewater from one level to another. They must be powerful enough to overcome the force of gravity and any friction that comes from the plumbing system. Valves work in conjunction with pumps to regulate flow and maintain system pressure.

Regular inspection and servicing of these components are essential to ensure that they operate efficiently. Maintenance checks include looking for wear and tear, as well as ensuring that valves open and close properly. Additionally, the selection of pumps is crucial; different types, such as submersible or centrifugal pumps, may be employed depending on the specific requirements of the lift station. Understanding the hydraulic characteristics of the system can lead to better energy efficiency and reduced operational costs, making it imperative for operators to stay informed about the latest advancements in pump technology.

Wet Well and Dry Well

The wet well is the area where wastewater is collected before being pumped away. It must be constructed to hold a sufficient volume of waste to ensure that pumps can operate smoothly without frequent cycling. Conversely, the dry well is where the pumps, piping, and controls are located, providing a dry and safe space for maintenance and repairs.

Understanding the function of both wells is vital for effective operation. Operators should regularly assess the condition of both areas, ensuring that they are functioning optimally. In addition to routine inspections, the design of the wet well should include features such as access hatches for cleaning and maintenance, as well as proper ventilation to prevent the buildup of harmful gases. The dry well should also be equipped with adequate lighting and safety measures, allowing maintenance personnel to work efficiently and safely. Implementing these best practices not only enhances the longevity of the lift station but also ensures compliance with environmental regulations, safeguarding public health and the ecosystem.

Understanding Lift Station Maintenance

Maintaining a lift station is non-negotiable for long-term functionality. Regular maintenance not only extends the life of the equipment but also prevents costly emergencies. The importance of this maintenance cannot be overstated, as lift stations play a crucial role in managing wastewater and stormwater, ensuring that these fluids are transported efficiently and safely away from populated areas.

Regular Inspection and Servicing

Proactive inspections play a key role in lift station maintenance. These involve checking mechanical, electrical, and structural components for signs of wear or failure. Scheduled service on pumps, valves, and control systems helps in identifying issues before they escalate into more significant problems. In addition to routine checks, it is beneficial to maintain detailed logs of inspections and repairs, which can provide valuable insights into the operational history and highlight recurring issues that may need further investigation.

Technicians should establish a routine maintenance schedule that includes lubrication, cleaning, and part replacement to keep the station running smoothly. This schedule should also incorporate seasonal considerations, as factors like heavy rainfall or freezing temperatures can impact the performance of lift stations. By adjusting maintenance tasks to account for these environmental changes, operators can enhance the reliability of the system throughout the year.

Dealing with Common Problems

Lift stations can encounter various issues, including pump failure, power outages, and blockages. Being prepared is essential. A systematic approach to troubleshooting enables operators to identify the root cause of problems quickly and implement necessary fixes. Utilizing diagnostic tools and software can aid in pinpointing specific malfunctions, allowing for more efficient repairs and minimizing downtime.

Training personnel in emergency response procedures can mitigate potential disasters, ensuring that any interruptions in service are addressed swiftly. Regular drills and refresher courses can keep staff well-prepared for unexpected situations, such as equipment malfunctions or severe weather events. This proactive training not only enhances safety but also builds confidence among the team, fostering a more resilient operational environment.

Preventative Measures for Longevity

Preventative maintenance is key to prolonging the lifespan of lift station components. This can include implementing measures such as regular water quality testing, monitoring flow rates, and employing advanced monitoring systems to detect irregularities early. By integrating technology such as IoT sensors, operators can receive real-time data on the station's performance, allowing for immediate action if any anomalies are detected.

Additionally, fostering a culture of accountability among the maintenance staff ensures that procedures are followed diligently, leading to fewer incidents and downtime. Encouraging open communication and feedback within the team can also lead to innovative solutions and improvements in maintenance practices. By recognizing and rewarding proactive behavior, organizations can cultivate a committed workforce that prioritizes the operational integrity of the lift station, ultimately contributing to the overall efficiency of wastewater management systems.

Safety Measures for Lift Station Maintenance

Maintenance of lift stations presents various safety risks, making it imperative to implement robust safety measures to protect personnel.

Personal Protective Equipment (PPE)

All personnel should wear appropriate personal protective equipment when working at lift stations. This may include gloves, hard hats, safety goggles, and high-visibility clothing. Ensuring that workers are equipped with the right gear minimizes the risk of injury and exposure to hazardous materials.

Training staff on the proper use of PPE is crucial to ensuring safety in the workplace, as adherence to these protocols helps prevent accidents. Regular inspections of PPE are also necessary to ensure that all equipment is in good condition and functioning properly. This proactive approach not only protects workers but also fosters a culture of safety within the organization, where employees feel empowered to prioritize their well-being and that of their colleagues.

Safety Protocols and Procedures

Establishing comprehensive safety protocols and procedures is essential for lift station maintenance. This includes proper lockout/tagout procedures before servicing equipment, hazmat response plans, and emergency evacuation routes.

Regular safety drills can ensure that all personnel are familiar with safety procedures, enhancing overall preparedness in case of unexpected situations. Furthermore, it is beneficial to conduct routine safety audits to identify potential hazards and areas for improvement. By involving employees in these assessments, organizations can leverage their firsthand experiences to enhance safety measures and create a more effective maintenance environment. Additionally, maintaining clear communication channels during maintenance activities can help in swiftly addressing any emerging safety concerns, thereby reducing the likelihood of accidents and ensuring a safer workplace for everyone involved.

The Future of Lift Stations

As technology evolves, so too do the systems we use for managing wastewater. The future of lift stations is likely to incorporate advanced technologies that improve efficiency and sustainability.

Technological Advancements in Lift Station Design

Recent advancements in lift station design feature smarter pumps, automated systems, and real-time data monitoring. These technologies contribute to more efficient operations and reduced energy consumption.

Additionally, implementing remote monitoring solutions can enable operators to manage lift stations from offsite locations, significantly enhancing operational control and response times. This capability allows for immediate alerts and diagnostics, which can prevent costly failures and minimize downtime. Moreover, the integration of artificial intelligence (AI) into these systems can predict maintenance needs and optimize pump performance based on varying flow conditions, further enhancing the reliability of wastewater management.

Sustainability and Lift Stations

With increasing focus on environmental sustainability, the design and operation of lift stations are adapting to meet greener standards. This may include the use of renewable energy sources, such as solar panels, and innovations in reducing discharge impacts on local environments.

Furthermore, integrating sustainable practices can also lead to cost savings over time, making the initial investment in modernizing lift stations not just an environmental imperative but also a financially sound decision. The use of green infrastructure, such as biofilters and constructed wetlands, can also play a role in treating wastewater naturally before it enters the lift station, thus reducing the burden on mechanical systems. Additionally, community engagement in sustainability initiatives can foster a greater awareness of water conservation, encouraging residents to participate in reducing overall wastewater generation.

As we look ahead, the role of lift stations in urban planning is becoming increasingly pivotal. With the rise of smart cities, lift stations are being integrated into broader infrastructure networks, allowing for enhanced data sharing and collaboration between various municipal services. This interconnectedness not only improves operational efficiency but also provides valuable insights into urban water management challenges, paving the way for innovative solutions that benefit both the environment and the community.