Understanding Residential Lift Station Pumps: A Comprehensive Guide

The Basics of Residential Lift Station Pumps

Residential lift station pumps play a crucial role in managing wastewater in residential areas, particularly those that are situated at lower elevations. These systems are designed to transport sewage and other wastewater materials from homes to a treatment facility or a municipal sewer system. Understanding how these systems work and their significance can help homeowners make informed decisions regarding their wastewater management needs.

What is a Lift Station Pump?

A lift station pump is a mechanical device that elevates wastewater to a higher elevation so it can flow downhill toward a treatment facility. Typically located underground, these systems consist of various components working in unison to ensure efficient waste movement. They are essential in areas where gravity alone cannot facilitate proper drainage.

The process encapsulates both the technology behind the pumps and the engineering skills needed to install and maintain them. When properly utilized, lift station pumps can significantly improve the efficiency of a home’s wastewater management system. These pumps are equipped with sensors and controls that monitor the wastewater levels, ensuring that they activate only when necessary, which helps conserve energy and prolong the life of the equipment.

Importance of Lift Station Pumps in Residential Areas

Lift station pumps are vital for homes located in low-lying areas, where the natural flow of wastewater may be impeded by terrain. Without these pumps, residents would face significant health hazards due to stagnant sewage and potential contamination of drinking water sources.

Moreover, these pumps prevent backups and overflows, protecting the environment and maintaining sanitation standards in residential communities. Their importance cannot be overstated, as they contribute directly to the well-being of households and communities alike. In addition to safeguarding public health, lift station pumps also play a role in preserving property values, as homes equipped with efficient wastewater systems are often more appealing to potential buyers.

Different Types of Lift Station Pumps

There are several types of lift station pumps, each designed for specific applications. The most common types include submersible pumps, which operate while submerged in the wastewater, and dry pit pumps, which are located outside the wastewater and can be maintained easily.

- Submersible Pumps: Ideal for smaller systems as they are efficient and minimize the risk of odors.

- Dry Pit Pumps: Easier to access for maintenance but require more space.

- Centrifugal Pumps: Commonly used for high-flow applications.

- Diaphragm Pumps: Useful for pumping sludge due to their ability to handle solids effectively.

Understanding these types allows homeowners to select the most appropriate solution for their specific needs. Additionally, the choice of pump can impact the overall efficiency of the wastewater system, as well as the frequency and cost of maintenance. Homeowners should also consider factors such as the pump's energy consumption and noise levels, as these can affect both utility bills and the comfort of living in close proximity to the lift station.

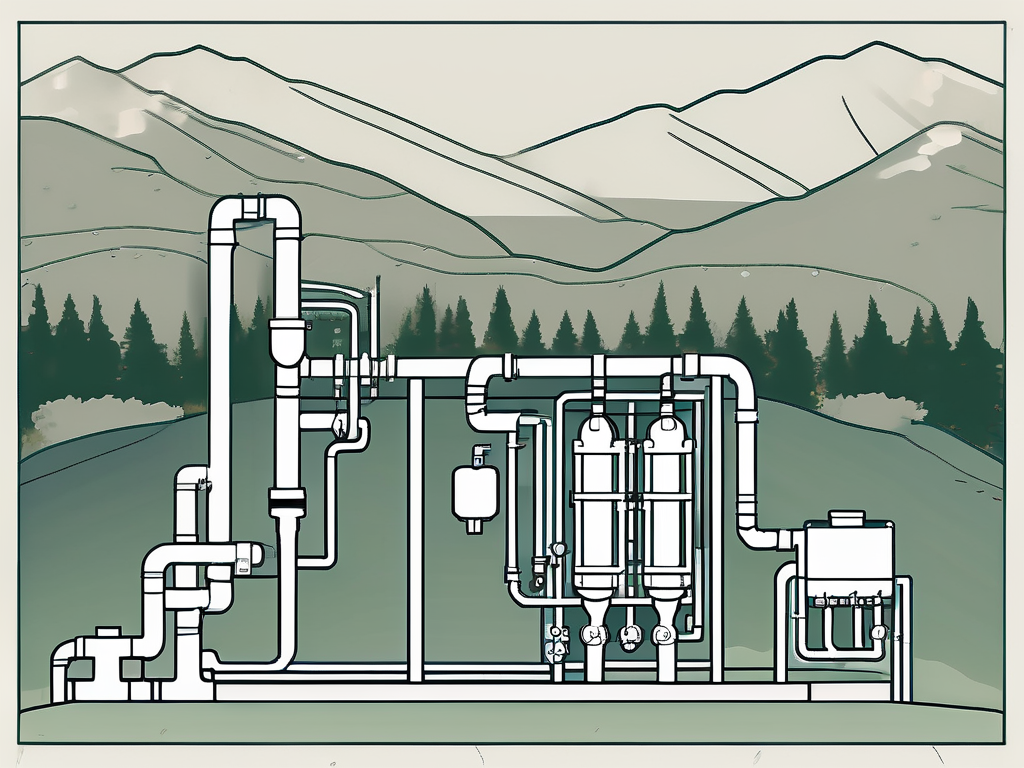

Key Components of a Lift Station Pump

To appreciate how lift station pumps function, it's essential to understand their key components. A well-designed lift station will have various parts working together to transport wastewater efficiently.

The Wet Well

The wet well is a vital component of any lift station, where the wastewater collects before being pumped out. The design of the wet well is crucial, allowing enough storage for the wastewater and ensuring that the pumps do not operate constantly, which can lead to wear and tear.

Regular monitoring of the wet well is essential to ensure optimal performance and adjust pumping schedules based on water levels. Additionally, the wet well's construction materials must be durable and resistant to corrosion, as they are constantly exposed to harsh wastewater conditions. Proper ventilation and odor control systems are also important to mitigate any unpleasant smells that may arise from the decomposition of organic matter in the wastewater.

The Control Panel

The control panel is the brain of the lift station pump system. It monitors various parameters, including water levels within the wet well, and automatically activates the pumps when necessary. Advanced control panels can also provide remote monitoring capabilities and alerts when maintenance is required.

Having a reliable control panel reduces the need for constant human oversight, making the system much more efficient. Furthermore, modern control panels often feature data logging capabilities, allowing operators to track performance metrics over time. This data can be invaluable for identifying trends, optimizing operations, and planning for future upgrades or expansions of the lift station system.

The Pumps

Pumps, as the primary components, drive the entire system and come in various designs and capacities. Different pumps have operational thresholds, and selecting the right one based on the required flow rate and head height is vital.

Regular maintenance of these pumps is crucial, as mechanical failure can lead to significant issues within the sewage system. In addition to routine inspections, implementing a predictive maintenance schedule can help identify potential problems before they escalate, thereby minimizing downtime. Some lift stations also incorporate backup pumps to ensure continuous operation during maintenance or unexpected failures, providing an added layer of reliability to the wastewater management process.

The Valves

Valves are essential for controlling the flow of wastewater in and out of the lift station. They can prevent backflow, control pressure, and manage flow rates. Regular inspections of valves are necessary to avoid malfunction, ensuring that the lift station operates smoothly without interruptions.

Valves should also be selected based on the specific requirements of the lift station, which can vary based on design and location. In some cases, specialized valves, such as check valves or gate valves, may be required to handle specific operational challenges. Additionally, the integration of automated valve systems can enhance the efficiency of the lift station, allowing for real-time adjustments based on changing conditions within the wastewater system. This adaptability is crucial for maintaining optimal flow and preventing potential blockages or overflows.

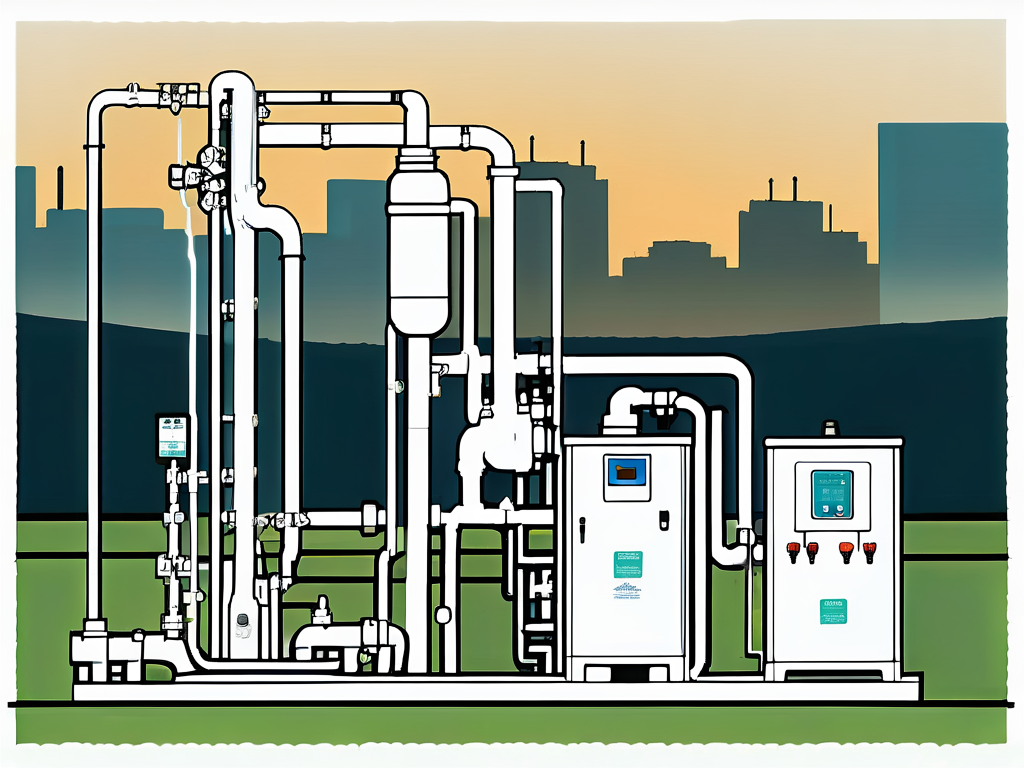

How Lift Station Pumps Work

Understanding the operation of lift station pumps is essential for effective wastewater management. These systems rely on gravity and pressure to function properly.

The Role of Gravity

Gravity plays a significant role in wastewater systems, and lift stations utilize it as much as possible. In proper design, the lift station relies on gravity for collecting wastewater in the wet well before pumping it out.

This "pull" of gravity allows for a more energy-efficient operation, as pumps only need to work harder when wastewater has accumulated to a specific level in the wet well. Additionally, the design of the wet well is crucial; it must be deep enough to accommodate fluctuations in wastewater flow while preventing overflow during peak usage times, such as during heavy rainfall or increased residential activity.

The Pumping Process

Once the wastewater level reaches a predetermined height, the control panel activates the pumps. As the pumps draw in the wastewater, it is propelled through the discharge piping toward the treatment facility or sewer line.

Understanding the pumping dynamics is essential, as fluctuating wastewater levels can impact efficiency, requiring timely maintenance and adjustments to pump operation. Furthermore, the type of pump selected—whether submersible or dry pit—can influence the overall performance and reliability of the lift station. Submersible pumps, for instance, are often preferred for their ability to handle solids and debris without clogging, making them ideal for environments with high levels of waste material.

The Discharge Process

After the wastewater has been pumped through the system, it undergoes the discharge process into the treatment facility. This stage ensures that the waste is appropriately treated to prevent environmental pollution and safeguard public health.

The efficiency of this process can vary based on the type of pump used, the landscaping of the area, and the infrastructure of the sewage system. Moreover, the discharge phase is closely monitored to ensure compliance with environmental regulations, as improper discharge can lead to significant ecological damage. Advanced systems may also incorporate flow meters and sensors to provide real-time data on wastewater levels and flow rates, allowing for proactive management and maintenance of the lift station to optimize performance and extend the lifespan of the equipment.

Maintenance and Troubleshooting of Lift Station Pumps

Proper maintenance of lift station pumps is critical to ensuring their longevity and efficiency. Regular check-ups can prevent minor issues from escalating into much more significant problems.

Regular Maintenance Tasks

Regular maintenance comprises various tasks, such as cleaning the wet well, checking electrical connections, and inspecting the pumps. Routine inspections should identify any wear and tear, which can lead to malfunction if not addressed promptly. Additionally, it is essential to monitor the pump's performance metrics, such as flow rates and power consumption, to detect any anomalies early on. Keeping a detailed log of these metrics can help in forecasting potential issues and planning for necessary maintenance.

Owner responsibility also extends to cleaning the area surrounding the lift station to minimize environmental contaminants impacting the system. This includes removing debris, vegetation, and any other materials that could obstruct access to the lift station or interfere with its operation. Regularly scheduled cleanings not only enhance the functionality of the lift station but also contribute to the overall aesthetic of the property.

Common Problems and Solutions

Some common issues with lift station pumps include clogs, mechanical failures, and issues related to electrical components. Identifying and troubleshooting these problems can save homeowners a significant amount in repairs. Furthermore, understanding the root causes of these issues can help in implementing preventative measures. For instance, educating residents about what can and cannot be flushed or drained into the system can significantly reduce the likelihood of clogs.

- Clogs: Often arise from non-biodegradable materials entering the system. Regular monitoring can mitigate this. Installing a screening system at the inlet can also help capture debris before it enters the pump, thereby reducing the frequency of clogs.

- Mechanical Failures: Regular inspections can help detect wear over time, allowing for timely repairs. Keeping an eye on the pump's vibration levels can also indicate mechanical issues; excessive vibration often signals misalignment or imbalance in the pump components.

- Electrical Issues: Conduct routine checks on the control panel and wiring to prevent electrical failure. Utilizing surge protectors and ensuring proper grounding can also safeguard against electrical surges that may damage sensitive components.

When to Call a Professional

Homeowners should not hesitate to contact a professional when they notice unusual sounds, odors, or repeated operational issues with their lift station pumps. A professional can identify underlying complications that may not be immediately apparent and ensure that repairs are carried out effectively. Moreover, professionals often have access to specialized diagnostic tools that can pinpoint issues more accurately than a standard inspection.

Ignoring small issues can quickly escalate into costly repairs, making preventative maintenance vital. Regular consultations with a licensed technician can also provide homeowners with valuable insights into the overall health of their lift station systems, helping them to make informed decisions about upgrades or replacements when necessary. By investing in professional expertise, homeowners can ensure that their lift station pumps operate smoothly and efficiently for years to come.

Choosing the Right Lift Station Pump for Your Home

Selecting the appropriate lift station pump is crucial for efficient wastewater management. Various factors come into play, such as type, capacity, and installation requirements.

Factors to Consider

Homeowners should consider several factors when selecting a lift station pump. Key considerations include the depth of the wet well, the volume of wastewater generated, and the distance to the discharge point.

More extensive arrays of pumps may be required for larger homes with increased wastewater needs, while smaller systems may suffice for minimal production. Additionally, the type of wastewater being handled—whether it is primarily greywater from sinks and showers or blackwater from toilets—can influence the choice of pump. Systems designed for handling solids may be necessary for blackwater applications, ensuring that clogs and blockages are minimized.

Understanding Pump Specifications

A proper understanding of pump specifications such as flow rates, horsepower, and discharge head is paramount. Homeowners should review the specifications to ensure a suitable match for their specific needs, aiming for a pump that can efficiently handle the expected wastewater demands. It is also important to consider the pump's efficiency rating, as a higher efficiency can lead to significant savings on energy costs over time. Moreover, understanding the noise level of the pump can be essential, especially for homes located near living areas, as some pumps can be quite loud during operation.

Cost and Installation Considerations

While costs vary based on pump type and size, homeowners should factor in both initial purchase costs and long-term operational efficiencies. Skilled installation is equally crucial, as improperly installed pumps can lead to premature wear or functional issues. It's advisable to obtain multiple quotes from licensed contractors to ensure competitive pricing and quality service. Furthermore, homeowners should inquire about warranties and maintenance plans, as these can provide peace of mind and protect against unexpected repair costs down the line.

Consulting with professionals ensures that the right pump is selected based on individual requirements and installed correctly to optimize performance. Regular maintenance, including routine inspections and cleaning, can extend the lifespan of the pump and maintain its efficiency, making it a vital aspect of wastewater management that should not be overlooked. Understanding the local regulations regarding wastewater management can also help homeowners avoid potential fines or compliance issues, ensuring that their lift station pump operates within legal parameters.

Environmental Impact and Sustainability of Lift Station Pumps

As global awareness of environmental issues grows, lift station pumps are also evolving to become more sustainable and efficient. Understanding their environmental impact is critical for both homeowners and municipalities alike.

Energy Efficiency

Recent advancements in pump technology have led to the development of energy-efficient models that minimize electricity use while maximizing output. This shift not only reduces operational costs for homeowners but also lessens overall carbon footprints. The integration of variable frequency drives (VFDs) allows pumps to adjust their speed according to the flow requirements, further enhancing energy savings. Such technologies can lead to significant reductions in energy consumption, making them an attractive option for both new installations and retrofitting existing systems.

Homeowners should consider energy ratings and efficiency specs when selecting pumps to contribute to sustainable practices. Additionally, opting for pumps that utilize renewable energy sources, such as solar or wind power, can further decrease reliance on fossil fuels and promote a greener lifestyle.

Waste Management

Efficient waste management is essential in mitigating pollution and ensuring public health. Lift station pumps play a significant role in this process, transporting wastewater effectively to treatment facilities for proper processing. The design of modern lift stations often includes features such as odor control systems and noise reduction technologies, which not only improve the surrounding environment but also enhance the quality of life for nearby residents.

Regular maintenance, along with the correct pump choice, aids in averting environmental hazards related to wastewater overflow and contamination. Implementing a proactive maintenance schedule can help identify potential issues before they escalate, ensuring that the lift station operates smoothly and efficiently. Moreover, community education on proper waste disposal practices can further support the effectiveness of lift station systems, reducing the likelihood of clogs and backups.

Sustainable Practices and Innovations

Innovations in lift station technology, including smart pumping systems that adjust automatically based on real-time data, are paving the way for more sustainable wastewater management practices. These systems reduce energy use and optimize performance, demonstrating a clear commitment to enhancing environmental stewardship. Furthermore, the use of advanced monitoring systems allows for remote management and diagnostics, enabling quick responses to any operational issues and minimizing downtime.

As technology continues to progress, homeowners and municipalities will find new ways to implement these innovations in their lift station systems for improved standards. The integration of IoT (Internet of Things) technology in lift stations can facilitate better data collection and analysis, leading to more informed decision-making regarding maintenance and upgrades. By embracing these advancements, communities can not only improve their wastewater management processes but also contribute to broader sustainability goals.

In summary, understanding residential lift station pumps equips homeowners with the knowledge needed to manage their sewage systems effectively. From basic functioning to maintenance, making informed decisions can ensure a smooth and environmentally-friendly waste management process.