Understanding the Benefits of a Bleach Injection System for Water Treatment

Understanding the Benefits of a Bleach Injection System for Water Treatment

In the realm of water treatment, the efficiency and effectiveness of systems in place are paramount to ensuring clean, safe water for public consumption and industrial uses. One such system that has gained popularity is the bleach injection system. This article explores the significant benefits of employing a bleach injection system in water treatment processes, providing insight into its functionality, advantages, and considerations.

What is a Bleach Injection System?

A bleach injection system is a specialized setup designed to inject sodium hypochlorite, commonly known as bleach, into water supplies. This process is primarily aimed at disinfection and helps in maintaining optimal water quality. The system ensures a precise and controlled release of bleach into the water, which can be pivotal in treating pathogens, organic materials, and other contaminants that affect water safety. The importance of such systems has grown significantly, especially in areas where water quality is a concern due to environmental factors or aging infrastructure.

Moreover, the use of bleach injection systems is not limited to municipal water supplies. They are also widely utilized in industrial applications, swimming pools, and agricultural settings, where maintaining water quality is crucial for health and operational efficiency. The versatility of bleach as a disinfectant makes it an invaluable tool in various sectors, ensuring that water remains safe for consumption, recreational activities, and agricultural use.

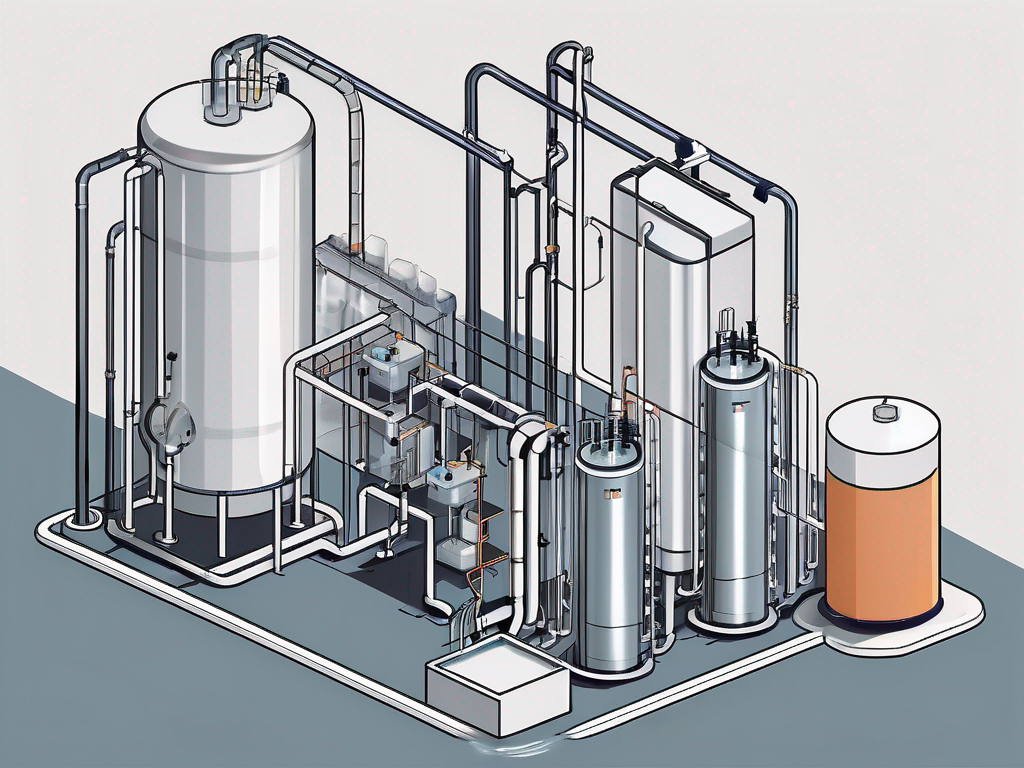

Key Components of a Bleach Injection System

The components of a bleach injection system are intricate yet essential for its operation. Key elements include a chemical feed pump, a solution tank, and appropriate piping and control systems. The chemical feed pump is responsible for delivering the bleach at a controlled rate, determined by the water flow rate and the necessary concentration levels. The solution tank holds the sodium hypochlorite until it is ready to be injected, while the piping connects the various components seamlessly. Each of these components plays a critical role in ensuring that the system operates effectively and safely.

Additionally, systems often include monitoring equipment to measure residual chlorine levels, alarms for malfunctions, and safety features to prevent leaks or over-injection. These monitoring systems are vital, as they provide real-time data that can help operators make informed decisions about adjustments needed in the treatment process. Furthermore, regular maintenance of these components is essential to ensure longevity and reliability, as any malfunction could lead to inadequate disinfection and potential health risks for users.

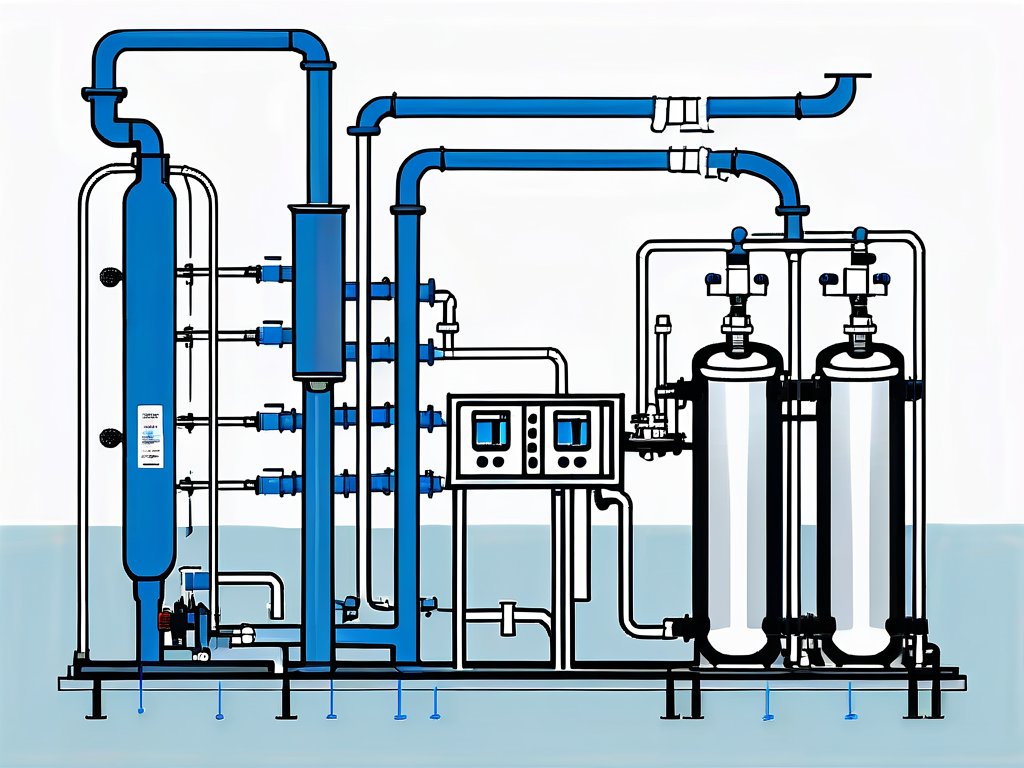

How Does a Bleach Injection System Work?

The operational mechanism of a bleach injection system is relatively straightforward. Initially, the bleach is stored in a solution tank at a designated concentration. When water enters the treatment process, the chemical feed pump activates and begins to inject the bleach into the water stream at a predetermined rate. This rate is crucial, as it must be calibrated to match the specific requirements of the water being treated, taking into account factors such as flow rate and contamination levels.

The injected bleach dissolves and interacts with the microorganisms present in the water. This interaction leads to the oxidation of bacteria and viruses, effectively disinfecting the water. Continuous monitoring ensures that adequate levels of bleach are maintained throughout the treatment process, safeguarding against potential contamination. Additionally, the system is designed to handle fluctuations in water demand, automatically adjusting the bleach injection rate to maintain consistent disinfection levels. This adaptability is particularly important in environments where water usage can vary significantly, such as during peak hours or in response to seasonal changes.

The Role of Bleach in Water Treatment

Bleach plays a crucial role in water treatment by helping to eliminate harmful pathogens and improve water quality. This powerful disinfectant is widely used due to its efficacy, availability, and ease of application. Understanding the science behind bleach and its interaction with water can elucidate its importance in this field.

The Chemistry Behind Bleach and Water Interaction

The primary active ingredient in bleach, sodium hypochlorite (NaOCl), dissociates in water to release hypochlorous acid (HOCl), a potent disinfectant. This reaction occurs rapidly, allowing for swift action against bacteria, viruses, and other pathogens. The effectiveness of bleach in water treatment is attributed to its ability to penetrate cell walls of microorganisms, leading to their destruction.

Moreover, the chemistry of bleach also allows it to react with various organic compounds, thereby oxidizing them and contributing to improved water clarity and safety. These interactions illustrate why bleach is a preferred choice in many water treatment applications. Additionally, the residual effect of bleach in water systems can provide ongoing disinfection, ensuring that any new contaminants introduced into the water supply are quickly neutralized, which is particularly important in preventing outbreaks of waterborne diseases.

Bleach as a Disinfectant: What You Need to Know

As a disinfectant, bleach has proven its efficiency in reducing the presence of harmful organisms that pose health risks. It is effective against a wide range of pathogens, which includes bacteria, algae, and viruses. This wide-spectrum efficacy is what makes bleach indispensable for municipal water treatment facilities, wastewater treatment plants, and even in residential settings.

However, it is vital to use bleach judiciously and in appropriate concentrations. Overuse can lead to by-products that may be harmful, highlighting the importance of adhering to recommended guidelines and regulations. For instance, the formation of chlorinated organic compounds, which can occur when bleach reacts with organic matter in water, necessitates careful monitoring and management. Ultimately, when used correctly, bleach serves as a reliable tool for ensuring safe drinking water. Furthermore, ongoing research into alternative disinfectants and methods continues to explore ways to enhance water treatment processes while minimizing potential risks associated with traditional chemicals like bleach, ensuring a safer and more sustainable approach to public health.

Advantages of Using a Bleach Injection System

Adopting a bleach injection system for water treatment offers a plethora of benefits that can significantly enhance the quality of water and streamline the treatment process. Understanding these advantages can aid stakeholders in making informed decisions regarding water treatment solutions.

Enhancing Water Quality

One of the most significant advantages of bleach injection systems is their ability to enhance overall water quality. By effectively eliminating pathogens, bleach ensures that the water is safe for consumption and other uses. This not only mitigates health risks but also promotes public confidence in water safety.

Furthermore, the oxidation properties of bleach help to break down organic matter and reduce odor, resulting in clearer and more palatable water. Enhanced water quality is particularly important for utility companies as they strive to meet regulatory standards and provide excellent service to customers. The ability of bleach to remove color and turbidity also plays a crucial role in improving aesthetic qualities, making water more appealing for recreational uses such as swimming and fishing.

Moreover, the effectiveness of bleach in controlling biofilm formation in distribution systems cannot be overlooked. Biofilms can harbor harmful microorganisms and lead to the deterioration of water quality over time. By regularly utilizing a bleach injection system, water treatment facilities can maintain cleaner distribution lines, thereby ensuring that the water delivered to consumers remains safe and of high quality.

Cost-Effectiveness of Bleach Injection Systems

Cost-effectiveness is another critical advantage of bleach injection systems. Compared to alternative disinfection methods such as chloramines or UV treatment, bleach injection systems generally have lower operational costs. Sodium hypochlorite is relatively inexpensive and widely available, making it cost-efficient for both large-scale municipal systems and smaller facilities.

Moreover, the ease of integration with existing water treatment processes minimizes installation costs. Reduced equipment and maintenance costs also contribute to long-term savings, making bleach injection an economically viable solution for water treatment. The scalability of these systems allows facilities to adjust their usage based on demand, ensuring that they are not over-investing in chemicals or equipment during periods of lower water consumption.

Additionally, the long shelf life of sodium hypochlorite means that facilities can stock up on supplies without worrying about rapid expiration. This not only reduces the frequency of orders but also allows for better budgeting and financial planning for water treatment operations.

Safety and Health Benefits

The safety and health implications of using a bleach injection system cannot be overstated. When properly handled, sodium hypochlorite presents a lower risk of exposure than some other disinfectants. Its rapid action in neutralizing pathogens reduces the potential for waterborne illnesses, ultimately protecting public health.

Additionally, advancements in monitoring and automation technology have significantly improved the safety of bleach injection systems. Real-time monitoring of chlorine levels and automated alerts for potential issues enhance operational safety and ensure compliance with health regulations. These technological innovations not only help in maintaining optimal disinfection levels but also provide operators with valuable data that can be used for continuous improvement in water treatment practices.

Furthermore, the implementation of safety protocols and training for personnel handling bleach injection systems is vital. By fostering a culture of safety and awareness, water treatment facilities can minimize the risk of accidents and ensure that staff are well-equipped to manage the chemicals involved. This proactive approach not only safeguards employees but also enhances the overall reliability of the water treatment process, ensuring that communities receive the highest quality water possible.

Potential Drawbacks of Bleach Injection Systems

Despite the numerous benefits, it is also essential to consider the potential drawbacks of bleach injection systems. Acknowledging these challenges allows for better decision-making and operational planning.

Handling and Storage Concerns

A key concern with bleach injection systems lies in the handling and storage of sodium hypochlorite. Being a hazardous material, bleach requires proper training for staff to safely manage and maintain the system. Risks related to spills, exposure, and degradation of the chemical over time necessitate diligent oversight.

Additionally, storage conditions must be carefully monitored to prevent accidents and maintain the integrity of the bleach solution. It is imperative that facilities implement rigorous safety protocols and ensure that all regulatory requirements are met. This includes using appropriate containment systems to prevent leaks and ensuring that staff are equipped with personal protective equipment (PPE) such as gloves and goggles. Regular training sessions can help reinforce safe handling practices and keep staff updated on any changes in safety regulations.

Environmental Impact Considerations

Environmental impact is another factor to consider when utilizing bleach injection systems. While bleach effectively treats pathogens, it can also result in the formation of disinfection by-products (DBPs) when reacting with organic matter in the water. Some of these by-products may be harmful and pose environmental risks, making it crucial to monitor their levels closely.

Moreover, the introduction of sodium hypochlorite into the water supply must be managed correctly to avoid any detrimental effects on aquatic ecosystems. Regulatory compliance and environmental stewardship should guide the operation of these systems to mitigate negative impacts. In addition to monitoring DBPs, facilities should consider alternative disinfection methods that may produce fewer harmful by-products. This could involve exploring advanced oxidation processes or ultraviolet (UV) disinfection, which may offer a more environmentally friendly approach while still ensuring water safety. Engaging with environmental experts can provide valuable insights into the best practices for minimizing ecological footprints while maintaining effective disinfection protocols.

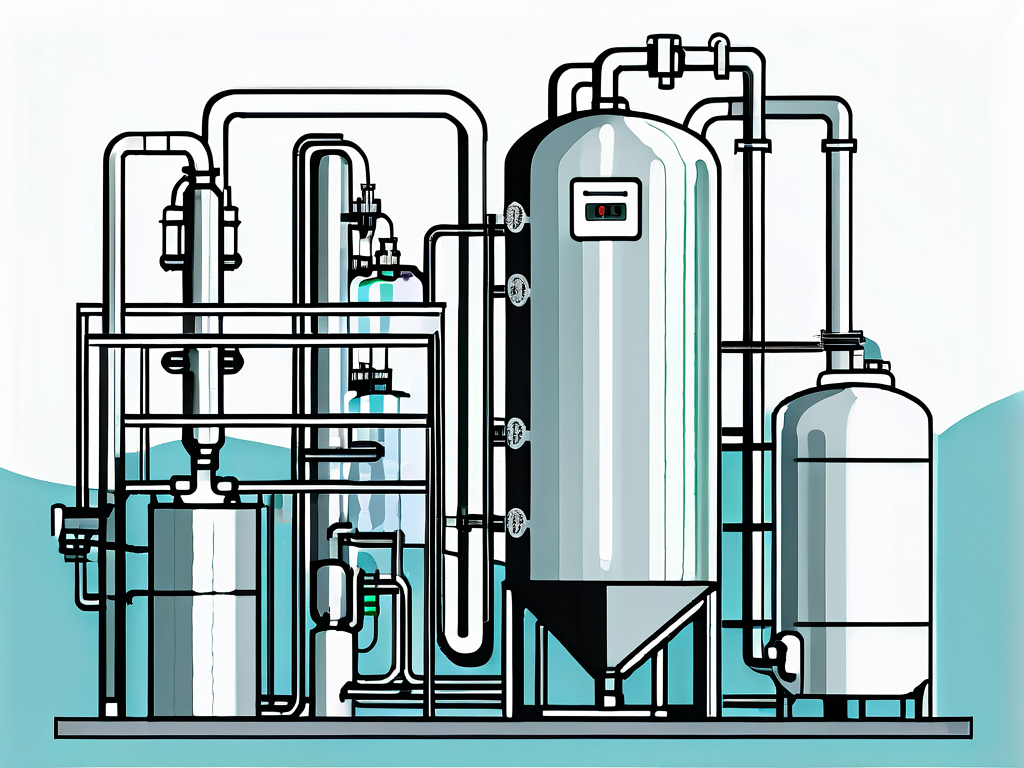

Choosing the Right Bleach Injection System

Selecting an appropriate bleach injection system is vital for ensuring the success of water treatment endeavors. Understanding the factors that influence this decision can help organizations invest wisely in their water management strategies.

Factors to Consider When Selecting a System

When assessing a bleach injection system, several factors should be taken into account, including the size of the facility, the volume of water treated, and specific treatment goals. It's essential to ensure that the system can handle peak flow rates and provide adequate disinfection levels.

Additionally, compatibility with existing infrastructure is crucial to avoid unnecessary modifications and costs. Consulting with experts and conducting a thorough needs assessment can lead to informed choices that align with operational goals. Furthermore, organizations should also consider the regulatory requirements specific to their region, as these can dictate the types of systems that are permissible and the standards they must meet. Understanding local regulations can save time and resources in the long run, ensuring that the selected system not only meets operational needs but also complies with legal mandates.

Maintenance and Upkeep of Your System

Once a bleach injection system is selected and installed, regular maintenance is vital to ensure its effective performance. Routine checks of components such as the feed pump, solution tank, and monitoring equipment are necessary to prevent malfunctions.

Moreover, staff training on proper maintenance procedures can significantly enhance system longevity and efficiency. Implementing a scheduled maintenance protocol ensures that any issues are promptly addressed, reducing downtime and maintaining reliable water treatment operations. In addition to routine maintenance, it is also beneficial to keep detailed records of all maintenance activities and system performance metrics. This documentation can help identify trends over time, allowing for predictive maintenance strategies that can preemptively address potential failures before they occur. By fostering a culture of proactive maintenance, organizations can optimize their bleach injection systems and ensure they consistently meet water quality standards.

Conclusion: Is a Bleach Injection System Right for You?

In conclusion, a bleach injection system can be an exceptional choice for water treatment, offering numerous benefits including enhanced water quality, cost-effectiveness, and safety. However, it is essential to consider the associated handling concerns and environmental impacts carefully.

Ultimately, the decision to implement a bleach injection system should align with the specific needs and capacities of your facility. By understanding the advantages and potential drawbacks, stakeholders can make informed decisions that contribute to effective and sustainable water treatment practices.