Understanding Well Water Chlorine Injection Systems: A Comprehensive Guide

Understanding Well Water Chlorine Injection Systems: A Comprehensive Guide

As the demand for clean and safe drinking water continues to rise, many homeowners with private wells are turning to chlorine injection systems as an effective solution. This comprehensive guide aims to provide insights into the intricacies of well water chlorine injection systems, including their functionality, benefits, and considerations for installation and maintenance.

The Basics of Well Water Chlorine Injection Systems

Understanding the fundamental components and operations of well water chlorine injection systems is essential for any homeowner considering this treatment method. These systems are designed to combat harmful bacteria, viruses, and other contaminants that may be present in well water, ensuring that the water is safe for consumption.

What is a Chlorine Injection System?

A chlorine injection system is a mechanical apparatus used to introduce chlorine into a water supply, specifically in private well systems. It operates on a straightforward premise: chlorine, a well-known disinfectant, is injected into the water to eliminate microorganisms that can pose health risks.

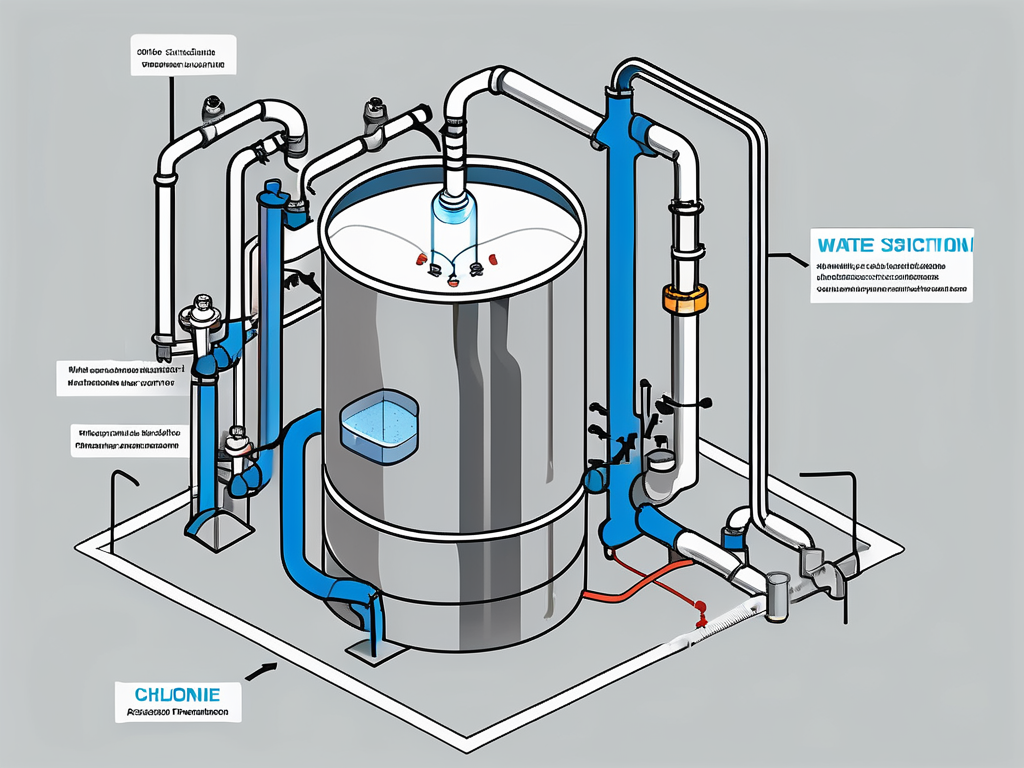

These systems can be configured in various ways, depending on the specific water quality issues a homeowner may face. The common goal remains the same: to purify well water and make it safe for human use. Typically, a chlorine injection system consists of a chlorine tank, a pump, and a mixing chamber, which work together to ensure that the chlorine is evenly distributed throughout the water supply. Homeowners can also monitor the levels of chlorine in their water, adjusting the dosage as necessary to maintain optimal disinfection without excessive chemical use.

Importance of Chlorine in Well Water Treatment

Chlorine plays a pivotal role in the disinfection of well water. It effectively destroys or inactivates a wide variety of pathogens, including bacteria like E. coli, viruses like Hepatitis A, and protozoa such as Giardia.

Furthermore, chlorine acts as a residual disinfectant, which means it continues to provide protection as water travels through pipes to faucets. This feature is vital because it helps to ensure that the water remains safe from recontamination. In addition to its disinfectant properties, chlorine can also help to oxidize and remove certain minerals and impurities, such as iron and manganese, which can cause staining and unpleasant tastes in water. By addressing both biological and chemical contaminants, chlorine injection systems offer a comprehensive solution for well water treatment, making them an invaluable tool for maintaining water quality in rural and suburban settings.

Components of a Chlorine Injection System

A well-designed chlorine injection system comprises several crucial components, each contributing to the overall efficiency of the disinfection process. Understanding these parts can help users appreciate how the system operates and respond appropriately to maintenance needs.

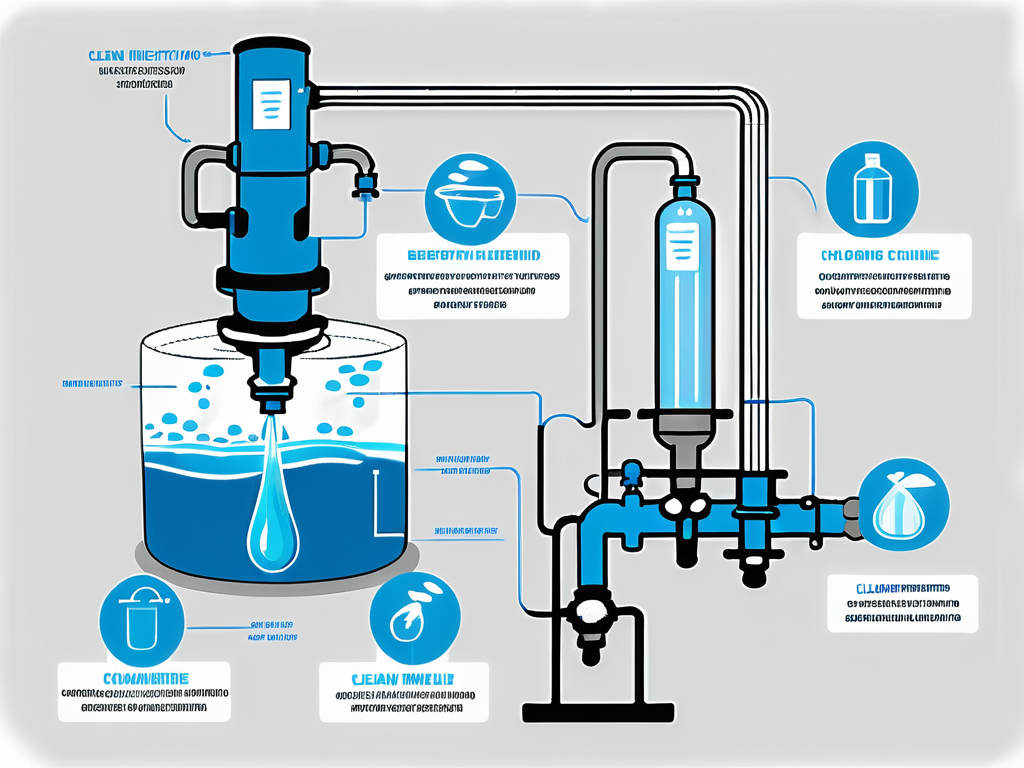

Chlorine Injector

The chlorine injector is the heart of the system, responsible for introducing chlorine into the water supply. It operates based on the principle of venturi, which creates a vacuum effect that draws chlorine solution from a tank and mixes it with the water. Proper adjustment of this injector ensures the correct dosage of chlorine is applied. Regular calibration of the injector is essential, as fluctuations in water pressure can affect the flow rate and consequently the concentration of chlorine introduced. Users should also be aware of the injector's maintenance schedule, as wear and tear can lead to inefficiencies and potential system failures.

Chlorine Solution Tank

This tank holds the liquid chlorine solution, which is typically a mix of sodium hypochlorite and water. The size of the tank may vary based on usage and should be monitored regularly to ensure it is filled adequately. A greater understanding of chlorine concentrations can lead to more effective treatment outcomes. Additionally, it is important to consider the tank's material and design, as these factors can influence the stability of the chlorine solution. For instance, UV-resistant materials can help prevent degradation of the solution due to sunlight exposure, thereby prolonging its effectiveness and ensuring consistent disinfection.

Injection Check Valve

The injection check valve serves as a preventive measure, ensuring that the chlorinated water does not flow back into the untreated well water. This component is vital for maintaining the integrity of the system and preventing contamination. Furthermore, the check valve must be inspected regularly for signs of wear or damage, as a malfunctioning valve can lead to backflow issues that compromise water quality. In some systems, additional safety features such as pressure relief valves or dual check valves may be employed to enhance reliability and safeguard against potential failures, ensuring that the disinfection process remains robust and effective.

Types of Chlorine Injection Systems

When exploring chlorine injection systems, it's crucial to recognize the various types available. Each system has unique characteristics that may make it more suitable for specific situations.

Liquid Chlorine Injection Systems

Liquid chlorine injection systems use sodium hypochlorite as a chlorine source. They are commonly utilized for disinfection purposes due to their ease of use and lower handling risks compared to gaseous forms of chlorine. These systems are ideal for homeowners looking for a straightforward and efficient disinfection solution. Additionally, liquid chlorine systems can be easily integrated into existing water treatment setups, making them a popular choice for both residential and small commercial applications. Their versatility allows for adjustable dosing rates, ensuring that the right amount of chlorine is used to maintain optimal water quality.

Furthermore, liquid chlorine systems often come equipped with advanced monitoring technology that helps track chlorine levels in real-time. This feature not only enhances safety by preventing over-chlorination but also ensures compliance with health regulations. As an added benefit, sodium hypochlorite has a relatively short half-life, which means it breaks down quickly in the environment, reducing the risk of harmful residuals in treated water.

Gas Chlorine Injection Systems

Gas chlorine systems, on the other hand, employ compressed chlorine gas delivered through carefully calibrated systems. While they can be more effective in certain scenarios, they also require specialized handling and precautions due to the potentially hazardous nature of chlorine gas. Therefore, these systems are often used in larger-scale applications, such as municipal water treatment facilities. The ability to inject chlorine gas in precise amounts allows for efficient disinfection over large volumes of water, making them indispensable in managing public health standards.

Moreover, gas chlorine systems are typically more cost-effective for large-scale operations, as they require less frequent replenishment compared to liquid systems. However, this efficiency comes with the necessity for stringent safety protocols, including the installation of leak detection systems and emergency response plans. Operators must be trained in handling chlorine gas and equipped with protective gear to mitigate any risks associated with accidental exposure. The robust nature of gas chlorine systems makes them a preferred choice for industries that demand high levels of water purification, such as food processing and pharmaceuticals, where water quality is paramount.

How Chlorine Injection Systems Work

The operational efficiency of chlorine injection systems is based on a sequence of well-defined processes. Understanding these processes can empower homeowners to use their systems effectively.

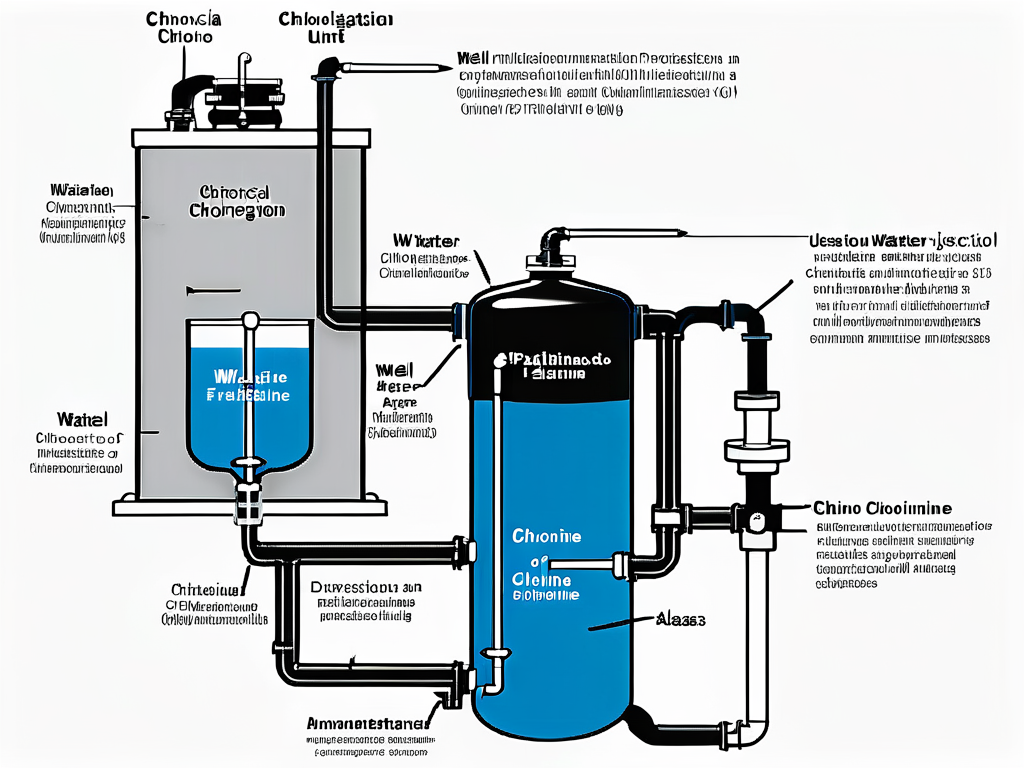

The Chlorination Process

The chlorination process involves several steps, beginning with the water draw from the well, followed by its passage through the chlorine injection system where chlorine is added. This mixture then flows through the plumbing into the home. The duration of contact time between chlorine and water is critical for effective disinfection.

Post-chlorination, the water is treated to remove any excess chlorine before it reaches the taps, which ensures that the drinking water does not carry an overwhelming chlorine taste or odor. This step is particularly important as it not only enhances the palatability of the water but also minimizes the formation of potentially harmful byproducts that can occur when chlorine interacts with organic matter in the water.

Moreover, the effectiveness of the chlorination process is influenced by various factors, including water temperature, pH levels, and the presence of other contaminants. Homeowners should be aware that fluctuations in these factors can affect the overall disinfection capability of the chlorine, making regular monitoring and adjustments necessary for optimal performance.

Maintaining Chlorine Levels

Maintaining optimal chlorine levels is fundamental for ongoing water safety. Regular testing is essential to ensure that the chlorine concentration remains within the desired range. Various test kits are available to aid homeowners in monitoring these levels.

Additionally, routine maintenance of the system components—including the injector and check valve—will help secure the performance and longevity of the system. This maintenance not only involves cleaning and replacing parts as needed but also checking for leaks or malfunctions that could compromise the system's efficiency. Homeowners should schedule periodic inspections, ideally with a professional, to ensure that all components are functioning correctly and to address any potential issues before they escalate.

Furthermore, understanding the signs of improper chlorine levels can be beneficial. For instance, if the water exhibits a strong chlorine smell or if there are noticeable changes in taste, these could indicate that the chlorine levels are too high. Conversely, if there are reports of bacterial contamination or if water tests show insufficient chlorine, it may suggest that the levels are too low. Being proactive in monitoring and maintaining chlorine levels not only safeguards health but also contributes to the overall reliability of the water supply.

Benefits of Using a Chlorine Injection System

The advantages of employing a chlorine injection system extend beyond just the elimination of pathogens. They contribute significantly to the overall quality of well water.

Improved Water Quality

One of the primary benefits is the notable improvement in water quality. Chlorination not only disinfects the water but also addresses issues like color, odor, and taste, leading to an overall better drinking experience.

In some cases, chlorination can even mitigate the presence of iron and manganese, further enhancing the water's palatability. This is particularly important for households that rely on well water, as these minerals can lead to staining of fixtures and laundry, creating additional maintenance challenges. By effectively managing these elements, a chlorine injection system helps maintain the aesthetic appeal of your home and prolongs the life of plumbing fixtures.

Protection Against Waterborne Diseases

Equipping your well with a chlorine injection system serves as a robust defense against waterborne diseases. For families, especially those with children or immunocompromised individuals, this added layer of protection reduces health risks associated with contaminated water.

In the face of potential contamination from surrounding agricultural runoff or natural interactions, the benefits of consistent chlorination cannot be overstated. Moreover, regular monitoring and adjustment of chlorine levels ensure that the water remains safe and clean, adapting to seasonal changes or fluctuations in water quality. This proactive approach not only safeguards health but also instills peace of mind for those relying on well water for their daily needs.

Cost-Effectiveness and Maintenance

Another significant advantage of a chlorine injection system is its cost-effectiveness over time. While the initial setup may require an investment, the long-term savings on water treatment and health care costs can be substantial. By preventing waterborne illnesses and reducing the need for frequent water testing and treatment, homeowners can allocate their resources more efficiently.

In addition, the maintenance of a chlorine injection system is relatively straightforward. Most systems are designed for ease of use, with automatic monitoring and dosing capabilities. This means that even those who are not particularly tech-savvy can manage their water quality effectively. Regular maintenance checks can ensure optimal performance, allowing families to enjoy clean, safe water without the constant worry of contamination.

Potential Drawbacks of Chlorine Injection Systems

While the benefits are significant, it is equally important to consider potential drawbacks associated with chlorine injection systems.

Chlorine Taste and Smell

Chlorine can impart a noticeable taste and odor to well water, which may be off-putting for some users. It may require additional treatment processes, such as carbon filtration, to mitigate these sensory issues.

Consulting with a water treatment professional can provide the best solutions for managing and reducing chlorine-related tastes and smells while still maintaining effective disinfection. In addition to carbon filters, other methods like reverse osmosis systems can also be employed to further purify the water, ensuring that users enjoy clean, fresh-tasting water without the harsh chlorine aftertaste. These solutions can enhance the overall drinking experience, making it more palatable for families and individuals who are sensitive to chlorine.

Health Concerns Related to Chlorine

Though chlorine is an effective disinfectant, the health implications of long-term exposure to chlorinated byproducts are an area of concern. Some studies indicate potential links to various health issues, prompting a need for careful management and oversight in its use.

Regular testing for chlorinated byproducts such as trihalomethanes (THMs) can help ensure that any risks are managed appropriately. Furthermore, it is crucial to stay informed about the latest research in water treatment technologies and health guidelines. Engaging with local water quality initiatives and participating in community discussions can provide valuable insights into the safety of drinking water and the effectiveness of various treatment methods. This proactive approach not only empowers individuals to make informed decisions but also fosters a greater understanding of the balance between effective disinfection and maintaining water quality standards.

Choosing the Right Chlorine Injection System

When considering the installation of a chlorine injection system, several factors should be taken into account. Proper selection can greatly enhance both efficiency and overall satisfaction with the system.

Factors to Consider

Homeowners should evaluate factors such as water usage, specific contaminants present in their well water, and local regulations regarding chlorination practices. Buying systems from reputable manufacturers substantiates product reliability and support. Additionally, understanding the flow rate of your water system is crucial, as it determines the appropriate size and capacity of the chlorine injection system needed to effectively treat your water without causing any adverse effects.

Seeking expert advice through consultations with water treatment specialists can lead to informed decisions that cater to individual household needs. These professionals can conduct comprehensive water testing to identify specific contaminants, such as bacteria or organic compounds, ensuring that the chosen system is tailored to address the unique challenges of your water supply. Furthermore, they can provide insights into alternative treatment options that may complement or enhance the effectiveness of chlorination, such as filtration systems or UV treatment.

Professional Installation and Maintenance

Professional installation is highly recommended to ensure that the system is set up correctly and functioning efficiently. Experienced technicians can advocate for best practices in managing the system and maintaining safety throughout the process. They will also ensure that all components, such as injection pumps and storage tanks, are installed in compliance with local codes and regulations, minimizing the risk of leaks or malfunctions.

Ongoing maintenance, including periodic checks and adjustments, is significant to preserve the longevity and effectiveness of the chlorination system. Regular service contracts with licensed professionals can offer additional peace of mind. These contracts often include routine inspections, calibration of the injection system, and replacement of parts as needed, which can help prevent costly repairs down the line. Moreover, maintaining a log of service records can be beneficial for homeowners, providing a clear history of the system's performance and any issues that may arise, ultimately contributing to a more reliable water treatment solution.

Frequently Asked Questions about Chlorine Injection Systems

Many homeowners have questions regarding the maintenance and operation of chlorine injection systems. Here are a few key queries often posed.

How Often Should the System be Checked?

It is recommended to check the system quarterly to ensure efficient performance and to conduct regular water sampling for testing chlorine levels and other contaminants.

Additionally, annual servicing by a professional can prevent more significant issues from arising, ensuring consistent and safe water quality.

What to Do in Case of System Failure?

In the event of a system failure, it is crucial to avoid using the well water until it has been investigated and resolved. Seek immediate professional assistance to diagnose the issue and implement repairs.

Having an emergency plan, including alternative water sources, is advisable for households relying solely on well water. Staying pro-active will help ensure health and safety are maintained.

In conclusion, well water chlorine injection systems are indispensable tools in safeguarding drinking water quality. Understanding their operation, benefits, and maintenance requirements sets the groundwork for making informed decisions that benefit your family's health and well-being.