Zero Liquid Discharge: Wastewater Treatment Explained

In the realm of wastewater treatment, Zero Liquid Discharge (ZLD) represents a pinnacle of innovation and efficiency. This method of treatment is designed to eliminate all wastewater discharge, ensuring that every drop of water is reused and no pollutants are released into the environment. This article will delve into the intricate details of ZLD, its processes, benefits, and applications.

Understanding ZLD requires a comprehensive grasp of its underlying principles, the technologies involved, and the various stages of the process. This article aims to provide an in-depth exploration of these aspects, shedding light on the complexities of this advanced wastewater treatment method.

Principles of Zero Liquid Discharge

The fundamental principle of ZLD is the complete elimination of liquid waste discharge from a system. This is achieved by recycling and reusing all wastewater, thereby reducing the demand for fresh water and preventing the release of pollutants. The goal is to create a closed-loop system where water is continuously cycled and reused.

Another key principle of ZLD is the recovery of valuable byproducts from the wastewater. During the treatment process, various substances are extracted from the wastewater, some of which can be reused or sold, thereby offsetting the cost of the treatment process.

Environmental Sustainability

The principle of environmental sustainability is at the heart of ZLD. By eliminating wastewater discharge, ZLD helps to protect water bodies from pollution, preserve water resources, and reduce the environmental footprint of industries. This aligns with global efforts to promote sustainable industrial practices and protect the environment.

Furthermore, by recovering valuable byproducts, ZLD contributes to the principle of resource efficiency. This not only makes economic sense, but also helps to reduce the extraction of natural resources, thereby contributing to sustainability.

Regulatory Compliance

ZLD also helps industries to comply with increasingly stringent environmental regulations. Many countries have implemented strict laws to limit the discharge of pollutants into water bodies. By achieving zero liquid discharge, industries can ensure full compliance with these regulations, avoiding penalties and enhancing their reputation.

Moreover, ZLD can help industries to future-proof their operations. As environmental regulations become even stricter in the future, industries that have already adopted ZLD will be well-positioned to comply with new requirements.

Technologies Involved in Zero Liquid Discharge

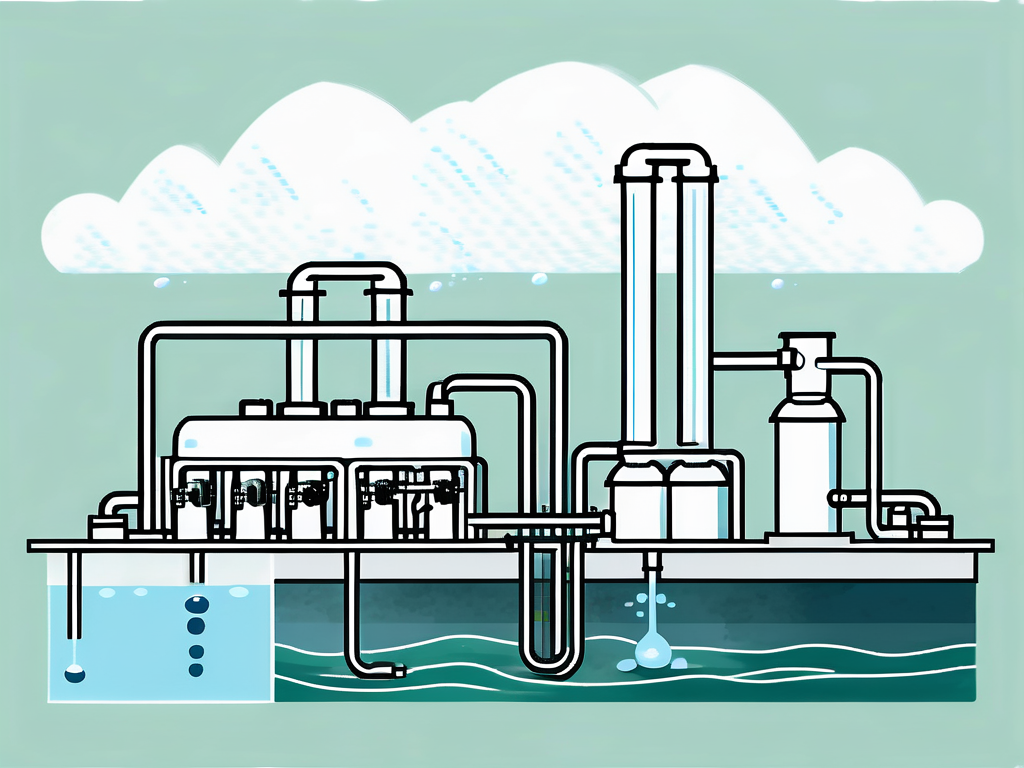

The implementation of ZLD involves a combination of several technologies, each playing a crucial role in the treatment process. These technologies are typically used in a sequence, with each stage of the process designed to remove certain types of contaminants and recover valuable substances.

The specific technologies used can vary depending on the characteristics of the wastewater and the requirements of the industry. However, the most common technologies involved in ZLD include pretreatment, evaporation, crystallization, and solid-liquid separation.

Pretreatment

Pretreatment is the first stage of the ZLD process. Its purpose is to remove large particles and substances that could interfere with subsequent stages of the process. This can involve various technologies, such as filtration, flotation, and chemical precipitation.

During pretreatment, substances such as oils, fats, and large particles are removed from the wastewater. This helps to prevent damage to downstream equipment and improve the efficiency of the subsequent stages of the process.

Evaporation

Evaporation is a key stage in the ZLD process. It involves heating the wastewater to evaporate the water, leaving behind a concentrated solution of contaminants. The evaporated water is then condensed and collected for reuse.

Evaporation not only helps to reduce the volume of the wastewater, but also enables the recovery of valuable substances. For example, certain salts can be recovered from the concentrated solution and reused or sold.

Crystallization

Crystallization is the final stage of the ZLD process. It involves further concentrating the solution left after evaporation, causing the remaining substances to crystallize. These crystals can then be separated from the liquid and disposed of safely.

Crystallization is a crucial step in achieving zero liquid discharge. It ensures that all remaining substances are removed from the wastewater, leaving only clean, reusable water.

Benefits of Zero Liquid Discharge

ZLD offers numerous benefits, both environmental and economic. By eliminating wastewater discharge, it helps to protect water resources and prevent pollution. It also reduces the demand for fresh water, contributing to water conservation.

From an economic perspective, ZLD can help industries to save money on water costs, avoid regulatory penalties, and generate revenue from the sale of recovered byproducts. It can also enhance the reputation of industries, making them more attractive to customers and investors who value sustainability.

Environmental Benefits

The environmental benefits of ZLD are significant. By eliminating wastewater discharge, it helps to protect rivers, lakes, and oceans from pollution. This not only benefits the environment, but also the communities that depend on these water bodies for their livelihoods and well-being.

ZLD also contributes to water conservation. By recycling and reusing all wastewater, it reduces the demand for fresh water. This is particularly important in regions where water resources are scarce or under stress.

Economic Benefits

From an economic perspective, ZLD can offer substantial benefits. By reducing the demand for fresh water, it can help industries to save money on water costs. It can also avoid regulatory penalties by ensuring compliance with environmental regulations.

Furthermore, by recovering valuable byproducts from the wastewater, ZLD can generate additional revenue. These byproducts can be reused within the industry or sold to other industries, thereby offsetting the cost of the treatment process.

Applications of Zero Liquid Discharge

ZLD can be applied in a wide range of industries, from manufacturing to power generation. It is particularly useful in industries that produce large volumes of wastewater or that are subject to strict environmental regulations.

Some of the main industries that use ZLD include the textile, pharmaceutical, chemical, and food and beverage industries. However, the potential applications of ZLD are vast and continue to expand as the technology evolves.

Textile Industry

The textile industry is one of the largest users of ZLD. This industry produces large volumes of wastewater containing various pollutants, such as dyes and chemicals. By implementing ZLD, textile factories can eliminate wastewater discharge, recover valuable substances, and comply with environmental regulations.

ZLD can also help textile factories to save money on water costs and avoid regulatory penalties. Furthermore, it can enhance their reputation, making them more attractive to customers and investors who value sustainability.

Pharmaceutical Industry

The pharmaceutical industry is another major user of ZLD. This industry produces wastewater containing various substances, including active pharmaceutical ingredients (APIs), solvents, and other chemicals. These substances can be harmful if released into the environment, making ZLD an important tool for environmental protection.

By implementing ZLD, pharmaceutical factories can eliminate wastewater discharge, recover valuable substances, and comply with environmental regulations. This can help them to save money, avoid regulatory penalties, and enhance their reputation.

Challenges and Future Directions

While ZLD offers numerous benefits, it also presents certain challenges. These include the high energy requirements of the process, the need for skilled operators, and the disposal of the solid waste produced. However, ongoing research and development efforts are aimed at addressing these challenges and improving the efficiency and affordability of ZLD.

Looking to the future, ZLD is likely to play an increasingly important role in wastewater treatment. As water resources become more scarce and environmental regulations more stringent, the demand for ZLD is expected to grow. Furthermore, advances in technology are likely to make ZLD more efficient and affordable, expanding its potential applications.

Energy Requirements

One of the main challenges of ZLD is its high energy requirements. The process of evaporating and crystallizing the wastewater requires a significant amount of energy, which can make ZLD expensive to operate. However, advances in technology are helping to reduce these energy requirements and make ZLD more affordable.

For example, new types of evaporators and crystallizers are being developed that are more energy-efficient. There are also ongoing efforts to integrate renewable energy sources into the ZLD process, which could help to reduce its environmental footprint.

Disposal of Solid Waste

Another challenge of ZLD is the disposal of the solid waste produced. This waste contains the substances that were removed from the wastewater, and must be disposed of safely to prevent environmental pollution. However, the disposal of this waste can be expensive and complex, particularly in countries with strict waste management regulations.

One potential solution to this challenge is the further treatment of the solid waste to recover valuable substances. This not only reduces the volume of waste that needs to be disposed of, but also generates additional revenue. There are also ongoing efforts to develop new methods of waste disposal that are more sustainable and affordable.

Conclusion

ZLD represents a major advancement in wastewater treatment. By eliminating wastewater discharge, it helps to protect water resources, prevent pollution, and promote sustainability. It also offers numerous economic benefits, including cost savings, regulatory compliance, and the recovery of valuable byproducts.

While ZLD presents certain challenges, ongoing research and development efforts are aimed at addressing these and improving the efficiency and affordability of the process. Looking to the future, ZLD is likely to play an increasingly important role in wastewater treatment, contributing to the global efforts to protect our precious water resources and promote sustainable industrial practices.